By Tom Pawlak — GBI Technical Advisor

Wooden windows frequently become weathered and develop rot due to their constant exposure to the elements. Often times repairing a wood window is much faster, cheaper and more aesthetically pleasing than replacing it. Over the years we’ve been contacted by architects in search of instructions on how to repair this kind of damage using WEST SYSTEM Epoxy. The following method is what we share with them to restore weathered wooden sills, sashes and trim:

• Remove all the paint in the affected areas.

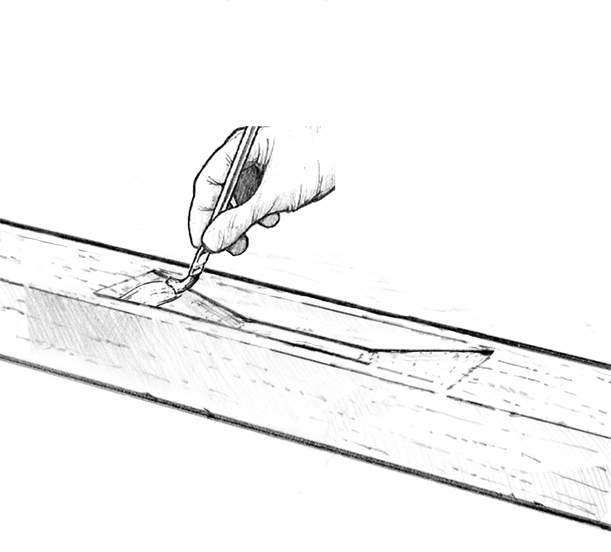

• Expose clean wood by opening up cracks and splits with a saber saw blade, broken hack saw blade, scratch awl or the tip of a pocket knife.

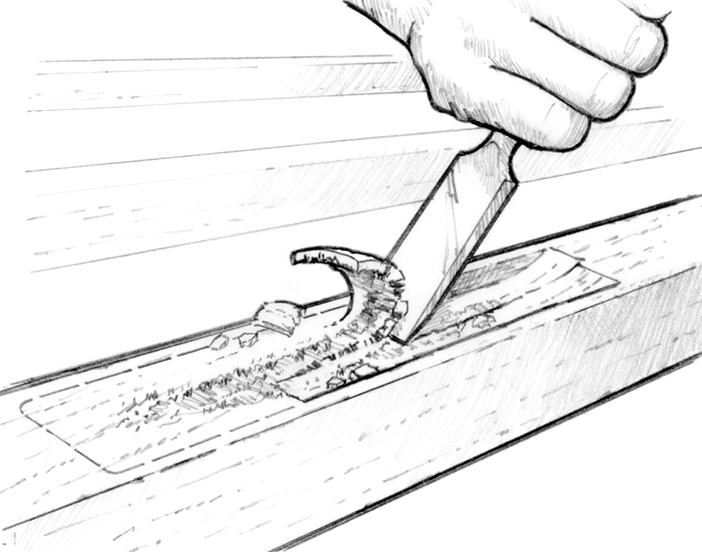

• Excavate rotted material and remove all loose, compromised or weathered wood fibers with a stiff hand-held wire brush worked parallel to the grain in the wood.

• Dry the surrounding area.

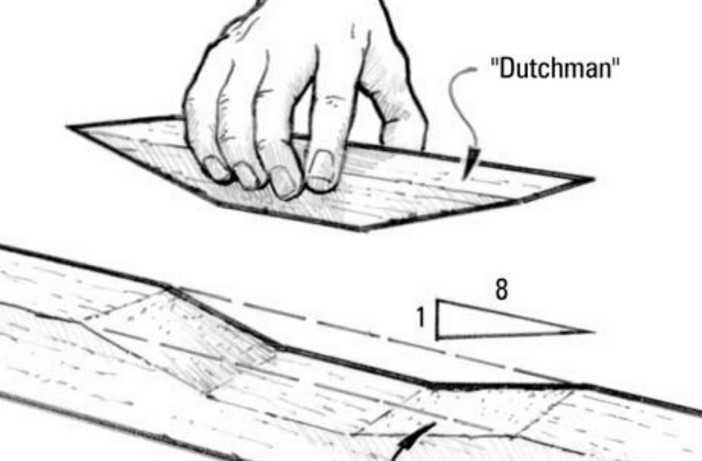

• If the cavity is more than ½” deep and a ¼” wide cut and fit a wood plug to fill the bulk of the cavity. Alternatively, gaps can be filled with thickened WEST SYSTEM® 105 Resin mixed with 206 Slow Hardener or 209 Extra Slow Hardener. Use 105 Resin with 205 Fast Hardener if working in temperatures at or below temperatures of 60°F (16°C).

• Care must be exercised because epoxy generates heat (exotherms) if applied in mass. Applying too much at one time will cause the epoxy to exotherm and smolder or in an extreme case, it can generate enough heat to catch fire.

• Follow the working temperature guidelines in the WEST SYSTEM Epoxy User Manual & Product Guide when selecting hardeners for the job.

• Coat the immediate area, the excavated cavity and wood plug with unthickened WEST SYSTEM Epoxy. Keep brushing the epoxy on until the wood will not absorb anymore. It will take multiple applications on the end grain to completely fill the pores.

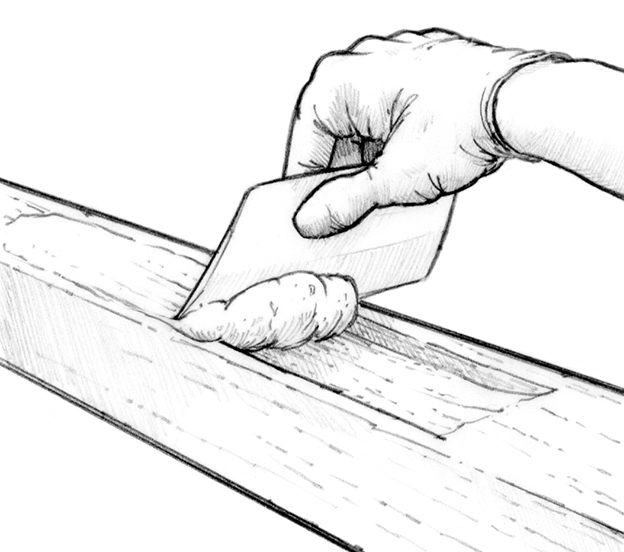

• Thicken the epoxy with one of the high-density fillers (406 Colloidal Silica, 403 Microfibers or 404 High-Density Fillers) to a mayonnaise consistency and apply it to the cavity.

• Press the wood filler piece (if any) into the thickened epoxy displacing much of it in the process.

• Clean up any excess epoxy.

• Allow the epoxy to cure until it becomes tacky.

• Apply epoxy thickened with 407 Low Density or 410 Microlight (mayonnaise consistency) to fill in any remaining low spots.

• Allow the epoxy to cure.

• Sand the low-density epoxy smooth and flush before applying a good, fast drying wood primer. The following primers have worked reliably over WEST SYSTEM Epoxy:

• Cover Stain Primer/Sealer made by Zinsser

• Bulls Eye 1,2,3 made by Zinsser

• Flash Bond 400 made by XIM

• Fresh Start, an acrylic-modified latex primer made by Benjamin Moore

• Alkyd based oil paint primers can be used over WEST SYSTEM Epoxy but they will dry slowly unless they are applied sparingly.

If you want to avoid sanding the epoxy, you can apply certain fast-dry house paint primers while the epoxy is still partially cured (rubbery). All of the previously listed primers can be used that way except the Alkyd based oil paint.

If you are restoring window frames, remove all the window glass and paint in the glass glazing areas. Abrade the surface with sandpaper or with a sharp wire brush and apply a coat of unthickened 105 Resin/Hardener to seal these surfaces and protect the wood from moisture absorption. Allow the epoxy to cure before sanding lightly and resetting windows in glazing putty.