WEST SYSTEM 105 Resin and 206 Slow Hardener recently passed a rigorous adhesive boil test performed by an independent laboratory. This test determines if a wood laminate and its adhesive is suitable for long-term use in a marine environment.

These tests were initiated to certify WEST SYSTEM Epoxy for use in a 38 meter sailboat scheduled for construction at Hodgdon Yachts, Inc. in East Boothbay, Maine. Hodgdon is building the boat for an Italian customer who wants it certified by Registro Italiano Navale (RINA). This certification requires that the boatbuilding materials pass the EN-314 Italian Boil Test for “outside”, a standard test for external glues other than phenolics.

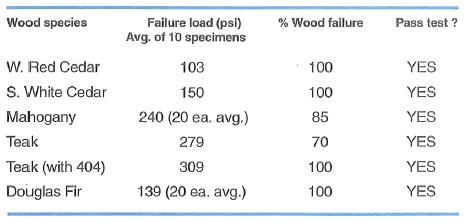

Gougeon Brothers, Inc. fabricated the western red cedar, southern white cedar, mahogany, Douglas fir and teak test specimens to Hodgdon’s specifications. They bonded all specimens (except one) with WEST SYSTEM 105 Resin and 206 Slow Hardener, thickened slightly with 406 Colloidal Silica at 1.7% by weight. One teak sample was bonded with WEST SYSTEM 105 Resin and 206 Slow Hardener, thickened slightly with 404 High-Density filler at 11% by weight.

Saginaw Valley State University (SVSU) in University Center, Michigan, conducted the tests, which expose the wood laminates to boiling water for 72 hours. The wood absorbs water and swells to its maximum size. This puts considerable stress on the wood/adhesive bond line. The test is completed by pulling the samples apart and recording the force required to pull the laminated wood specimen apart. The failure load is calculated by dividing the force required for failure by the cross sectional area in the test specimen.

SVSU technicians were unaware of the wood species and glue types used to fabricate the samples. Gougeon provided them only with sample numbers to differentiate the samples.

In order to pass the test, the WEST SYSTEM laminates had to meet the following criteria: When the failure load is 29 psi to 58 psi, there must be at least 80% wood failure in the test section. When the failure load is 58 psi to 87 psi, there must be at least 60% wood failure. When the failure load is 87 psi to 145 psi, there must be at least 40 % wood failure. When the failure load exceeds 145 psi, the laminate passes regardless of the mode of failure.

All of the wood species laminated with WEST SYSTEM easily surpassed the minimum requirements of the test. The results are shown in the table below.