by Tom Pawlak — GBI Technical Advisor

Above: Tom’s wife Mary paddles aboard her Gougeon 12.3 kayak on the Rifle River Recreation area in Lupton, Michigan.

I recently modified the deck of my wife Mary’s fiberglass canoe (one of dozens built from the Gougeon 12.3 mold) to make it more seaworthy and to facilitate a spray skirt. More like a kayak. Previously, the decks covered only the ends of the boat, leaving the middle 40% wide open. I’m fairly pleased with how it turned out.

I’m thinking of making a quick mold off of the deck this winter so Gougeon employees can make the same deck for their boats if they wish. The original decks were made off of the bottom and near the ends of the mold that produced the hull. To extend these decks, I just made fiberglass parts off of the bottom of the boat, cut them to size, glued them in place, faired it all in, and painted.

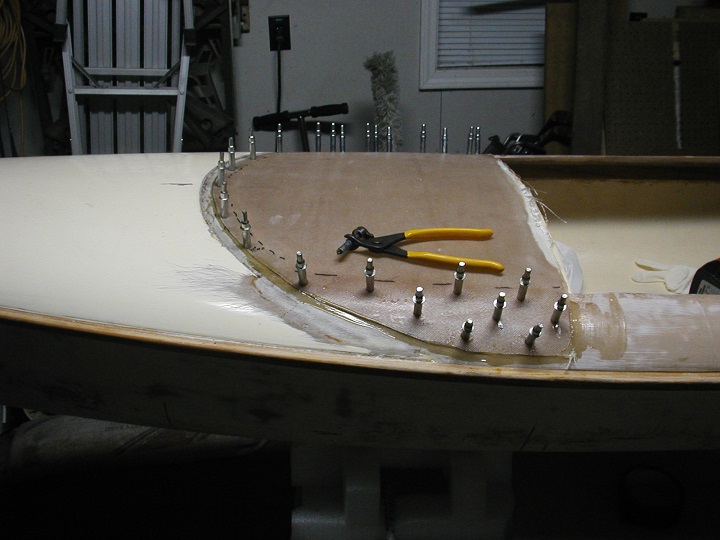

I borrowed a bunch of Cleco clamps and the Cleco tool that installs and removes the clamps to temporarily hold the pieces in place while the glue hardened. What a great invention. The aluminum skinned aircraft builders use them to position panels before final assembly. Cleco clamps are available from www.eastwoodco.com.

The deck extensions were molded off of the bottom of the kayak in four separate panels. I mold released the bottom of the boat so I could use it as a male mold.

From this, I made two 10″-wide × 7′-long fiberglass panels (one from each side of the boat) from the turn of the bilge area (at the waterline) and centered along the length of the boat. These molded shapes became the deck along each side of the cockpit. Then I made a panel 3′ in from each end that extended from the turn of the bilge on one side to the other.

These panels were used to extend my original decks that were about 3½’ long each. The panels were all glued together with lap joints of fiberglass and faired before being painted by brush with one-part polyurethane paint.