By Russell Brown — Port Townsend Watercraft

The PT Skiff is a fuel-efficient center console runabout that looks good, handles well, and can carry a load. It is very quick with only 20 horsepower.

We studied the hull shape of the PT Skiff with the most advanced design tools seeking maximum fuel efficiency and good performance under various speeds, loads and conditions. The prototype proved to go 22 knots lightly loaded and made over 16 knots with four people and gear. The hull is fairly narrow, which allows for its uncommon efficiency and a more comfortable ride in rough weather.

Water ballast provides the option of extra weight to add stability in this light and relatively narrow boat. Ballast is used when at the dock and can also make the boat ride better in wind and chop.

The tank is part of the structure of the boat. It fills and drains automatically. The ballast can either be kept in, or kept out by locking the air vent valve located near the steering wheel.

Other design features make this boat travel comfortably in rough weather. A fine entry to reduce pounding, high freeboard, and lots of flare in the topsides helps to keep you dry. The deep forward cockpit is comfortable and feels secure.

To develop the PT Skiff as a kit boat for commercial sale, we modified it and built a second prototype. The original design needed foam flotation in many of the compartments in order to comply with USCG requirements.

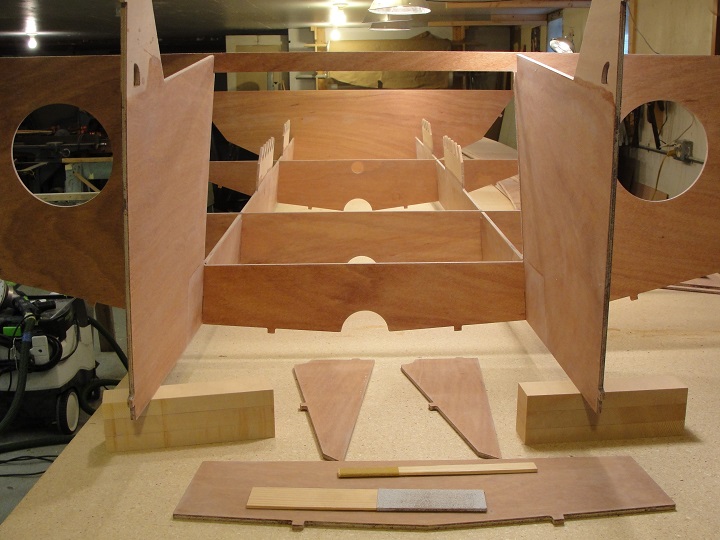

Much of the flotation needed is to provide stability in the case of a swamped boat, so it made sense to put some of this buoyancy at the outer edges of the boat. While building the first boat we were already considering side decks as a way to simplify construction, so we chose to redesign the boat with side decks and allowed for 3″ of foam to be fitted in the space underneath.

The PT Skiff is built from plywood and epoxy for lightweight, longevity, ease of construction, and minimal cost and waste. One would have to use materials such as carbon fiber and honeycomb to produce a boat that weighs less, and these materials would only beat wood/epoxy in one of the four factors mentioned above.

Boatbuilding with wood and epoxy is not hard, but it is a science. To build a lightweight boat that is both strong and long-lasting, one must understand the materials. This is why the manual that accompanies the kit is as much about the technology as it is about building the boat.

The kit is cut from 12 sheets of Lloyds approved BS 1088 Okoume marine plywood. It is a high-quality wood and is the best product for the purpose. The pieces go together quickly and perfectly. Longer pieces are joined with puzzle joints that align them both vertically and horizontally, and all 10 frames are located with tongues that fit into slots in the hull, so there is not much measuring. The kit also includes gluing cleats (inside corner reinforcement) that are pre-cut to size and length.Building this boat is within the means of talented amateurs with general hand tool skills, as long as they carefully follow the manual. The resulting boat is very advanced. One was recently built by students at the Northwest School of Boat Building (see page 24) and is for sale through the school.

The manual for the PT Skiff is highly detailed, with step-by-step text and photos. Additional portions describe various construction techniques. To produce the manual, we built and tested the completed Mark II boat shown in the photos. We were as careful in composing the manual as we were in designing the boat and assembling the kits. These construction photos and images are of the skiff currently being offered by PT Watercraft, located in Port Townsend, Washington. There are performance videos and a blog with more on the website at www.ptwatercraft.com.

PT Skiff Specifications

- LOA: 18’4″ (5.6m)

- Beam: 6′ (1.63m)

- Draft: 15″ (.38m)

- Water Ballast: 37.5 gal (142L) 321 lbs

- Engine: 20hp 4-stroke

- Fuel Capacity: 6 gal portable tank

Plans are available through ptwatercraft.com