by Brian Knight—GBI Technical Advisor

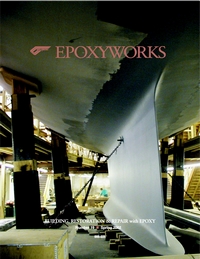

Above: Scheherazade, the 154’7″ yacht that required testing of large bonded-in fasteners.

Scheherazade is a 154′ 7″ Bruce King-designed ketch under construction at Hodgdon Yachts, in East Boothbay, Maine. Scheherazade is 60% larger than Antonisa, the last Bruce King/Hodgdon Yacht collaboration, and is the largest sailboat under construction in the United States.

We first looked at Scheherazade in EPOXYWORKS 17, Spring 2001, before she was rolled and set on her 153,000 lb ballast keel. On a March 2002 visit, Scheherazade was resting on her massive keel (cover), while far above, surrounded by multiple levels of staging, work continued on her interior and deck.

A yacht this size will generate some huge loads on the structure and on the hardware. It also generated some large-scale testing at Gougeon Brothers, Inc.

Hardware bonding is a technique for installing hardware and metal fasteners in ways that take full advantage of epoxy’s excellent physical properties. Hardware bonding is being used in important ways in the construction of Scheherazade. Much of the hardware on this boat is attached by bolts that do not have a nut and washer attached—they are simply glued into a blind hole. For the most part, this hardware and its fasteners carry heavy loads. For example, the propeller shaft strut is attached to the hull by several 1½” diameter silicon bronze bolts that are glued into Douglas fir blocking in the hull. They are not through-bolted. Additionally, the backstay chainplates are bonded into the shear clamp with ¾” stainless steel threaded rod.

This yacht is being built to the specifications of Lloyd’s Register of Shipping. Lloyd’s requested that we perform a series of tests to determine the amount of force necessary to extract some sample large bonded-in fasteners. Test samples had to reflect the construction methods used on Scheherazade, and the fasteners had to be the same 1½” diameter and alloy as used on the boat. Hodgdon Yachts was kind enough to supply us with the proper fasteners.

Preliminary testing

Although we have volumes of test data on end grain hardware bonding, we were uncertain of the force required to remove the bolts from edge grain and flat grain Douglas fir. Because of this, we decided to run two preliminary tests to give us a better idea of the magnitude of force required.

For the preliminary tests, we used a Douglas fir laminate left over from a previous test program. This laminate was made of four layers of ¾” Douglas fir bonded together to make a 3″ thick panel; from this, we cut two 12″×12″ test pieces.

For the preliminary tests, we bonded a ¾”×18″ threaded steel rod into a 1″ diameter hole drilled in the center of each panel. We drilled a 2″ deep hole in one panel and a 3″ deep hole in the other panel. To center the rod in the hole, we glued small, 1/8″ thick chips of cured epoxy to the rod near its end and at the point where the rod exited the hole. These epoxy spacers were glued approximately 120° apart around the circumference of the bolt. The bonding adhesive for this test was WEST SYSTEM® 105 Resin and 206 Hardener with no fillers or additives.

We used the MTS Test Machine to extract the large bonded-in fasteners. It is capable of generating 100,000 lb of force. It can accurately record the force exerted on the fastener at any time as well as the amount of deflection in the entire system.

The bolt embedded 2″ into the laminate required 8,908 lb of force to pull the bolt loose. The bolt embedded 3″ into the laminate required 13,948 lb. From these two tests, we could predict the force required to remove the fasteners in the tests required by Lloyds.

Required tests of large bonded-in fasteners

Lloyd’s requested that we test both the ¾” diameter stainless steel bolts that would be used to anchor the running backstay hardware and the 1½” diameter silicon bronze bolts that would hold the propeller strut to the hull.

The samples for the required tests were somewhat different than those of the preliminary tests. Lloyd’s requested that we test several different embed depths, some deep enough to result in the bolt breaking before being pulled from the laminate. We suggested that the bolt should be extracted from the laminate, not broken. Breaking the bolt would tell us only the strength of the bolt, but not the strength of the bolt/epoxy/wood assembly. From the preliminary tests, we calculated the deepest embed that would allow the fastener to be extracted without breaking the bolt. By testing several different embed depths, we would be able to predict how deep a fastener would have to be embedded to perform as designed: that is, the minimum fastener embed depth that will produce a failure in the rod rather than the glue joint.

The large bonded-in fasteners test specimens

For the tests on the ¾” stainless steel rods, we built seven laminated wood blocks, 12″×24″×5½” thick. All were laminated ¾” clear Douglas fir. The photo (below) shows how the bolt was oriented relative to the grain of the wood. We drilled one ” diameter hole into each of these samples and bonded a rod in the center of each hole. Two of the rods were embedded 5″ deep and five rods were embedded 6″ deep.

Additionally, Lloyd’s requested two more tests on the much larger 1½” silicon bronze fasteners that would be used to hold the propeller strut to the bottom of the hull. The force required to extract these large bonded-in fasteners was expected to be very large (50,000 lb+), so we increased the size of the panel to 24″×24″×12″ thick. The wood grain is oriented differently in this test than in the ¾” rod test (below). This reflects the way the grain is oriented in the hull of the boat. Each fastener was bonded into a 1″ hole drilled 9″ deep.

The test apparatus

The end of the bonded-in fastener is threaded into a socket on the actuating cylinder on the base of the test machine. The test is performed by pulling the bonded threaded rod downward out of the woodblock. We knew that we needed a very substantial method of holding the wood sample up while the fastener is withdrawn from it.

The woodblock is held in a ” steel angle frame. The frame is suspended by six 1″ threaded steel rods attached to a wood/steel composite slab just below the top of the test frame. The slab is a 4½” thick plywood core sandwiched between two pieces of ¼” steel, bonded together with epoxy, and nicknamed “the Monolith” (from the movie 2001: A Space Odyssey). The Monolith is anchored to the crosshead of the MTS Test Frame with a 2″ diameter bolt. At the very top of the test apparatus is the cylindrical load cell, which measures the force the machine is exerting on the fastener.

It is not an easy thing to hold onto a piece of wood and pull on the other side of it to the tune of more than 50,000 lb, but that is exactly what we hoped our apparatus would do. Between the frame, the six steel threaded rods, the Monolith, the 2″ diameter bolt, the 1½” silicon bronze threaded rod, and a test machine with a pulling capacity of 100,000 lb, something has to go. We hoped it would be the epoxy joint or the wood, not the fixture or the test machine.

The test procedure

The force on the 1½” threaded rod was “ramped up” in a steady progression starting at zero. A load of 10,000 lb was added every minute (3500 lb/minute on the ¾” rod test). Except for the muffled pounding of a hydraulic pump and a line moving steadily upward on a computer screen, nothing much seemed to be happening in the first minutes of the test-until the sound of a small pinging crack. The weight of another SUV was added… another crack. Moments later, in a progression of cracking terminating in a loud 27-ton crunch, the block gave up the threaded rod. In five minutes, the test was over. In both tests, the machine’s travel limit was set to 1″, so the rod remained partially embedded in the block.

Conclusions

It took an average of 22,000 lb of force to remove the ¾”×6″ embed, 19,400 lb to remove the ¾”×5″ embed and 55,000 lb of force to remove the 1½”×9″ embed silicon bronze rods. The force required in pounds per square inch of hole surface area ranged from 1,000 to 1,600 psi depending on the quality of the wood in the test sample.

The test provided the information necessary to determine the embed depth necessary to result in a bolt failure rather than a glue/wood failure. The test also proved conclusively that if you really want a fastener to hold, bonding it in with epoxy will do the job.

Further observations on large bonded-in fasteners

A tested 12″×24″×5½” sample was split apart after a test. This sample had a large crack running the complete length of the sample after the test had finished (below left). I drove a wedge into the crack, which split the block the remaining distance. The photo (below right) shows how the wood adjacent to the threaded rod was destroyed-graphic evidence of the forces exerted during this test.

A tested 24″×24″×12″ sample was cut apart on a large band saw so we could examine what happened in the area around the bolt. The photo above shows that the wood was permanently deflected around the bolt. You can see the distortion in the glue line where the wood was bent in the direction of the bolt movement. The wood fiber closest to the bolt is distorted more than the fiber farther from the bolt. This is the result of the wood compressing near the bolt and crushing. Farther away from the bolt, the distortion becomes less noticeable until, a few inches from the bolt, there is no visible deflection.