Testing Epoxy’s Adhesion to White Oak

By Bruce Niederer — GBI Technical Advisor

People have been building boats using white oak for centuries, sacrificing blood, sweat, and tears to engineer wonderful and enduring vessels of all shapes and sizes.

Oak was often used because of its desirable properties and behavior. It is dense, strong, rot-resistant, holds fasteners well, and can be steam bent. In the days before glues and adhesives, oak planking was used because it would swell considerably which resulted in tight and sound hulls, meaning little leaking and dry interiors. Of course, time marches inexorably forward, and eventually, builders began using adhesives to augment or, in some cases, replace mechanical fasteners.

We’ve been debating the issue of gluing oak ever since.

These days white oak is used more for keel timbers and frames, less so for planking. Regardless of the application, adhesion, while certainly important, is only part of the equation necessary for success. Still, it’s a good place to start. There are many who argue that adhesives have little use or no place in wooden boats. Sometimes that statement is qualified to apply only to “traditional” wooden boat construction. We have over 40 years of experience, data, and history to support our argument to the contrary and I will share some recent test data here. So get ready people— it’s GBI as Mythbusters.

When we say adhesion what we are referring to is tensile adhesion measured with our PATTI instrument according to ASTM D-4541 (results below). There are no peel or shear forces involved.

| Tensile adhesion test results | ||

| Adhesive | Surface prep | Average adhesion |

| 105/205 | 80-grit sanding + alcohol wipe ×2* | 1,864 psi |

| G/flex 650 | 80-grit hand sanding | 1,935 psi |

| G/flex 655 | 80-grit hand sanding | 1,780 psi |

| G/flex 655 | 80-grit sanding + alcohol wipe ×2* | 2,212 psi |

| *70% isopropyl alcohol in water | ||

The PATTI test uses compressed air to pull an aluminum stud from the surface of the test material to which it is bonded. It records the force required to break the bond in pounds per square inch.

What we learn from this data is surface prep can make a difference in adhesion as well as the choice of epoxy. While G/flex® yields significantly better values, standard WEST SYSTEM® 105 Epoxy Resin®/206 Slow Hardener® did pretty well without any surface prep at all, which does lend some support to our stated position that epoxy can bond white oak. But as I said, this is only one part of the story.

To get a more complete understanding of adhesion to white oak we recently completed short block shear testing according to ASTM D-905. We had two goals: first, to test adhesion to white oak under a shear load, and second, to collect some more data on our new Six10® Adhesive. All the specimens in this sample population were hand sanded with 80-grit followed by a thorough wipe with alcohol pads. The load is applied to the sample in the direction of the grain. The results are as follows:

| White oak short-block shear test results | |

| Adhesive | Average shear strength |

| 105/206 | 2,866 psi |

| G/flex 650 | 2,968 psi |

| Six10 | 2,834 psi |

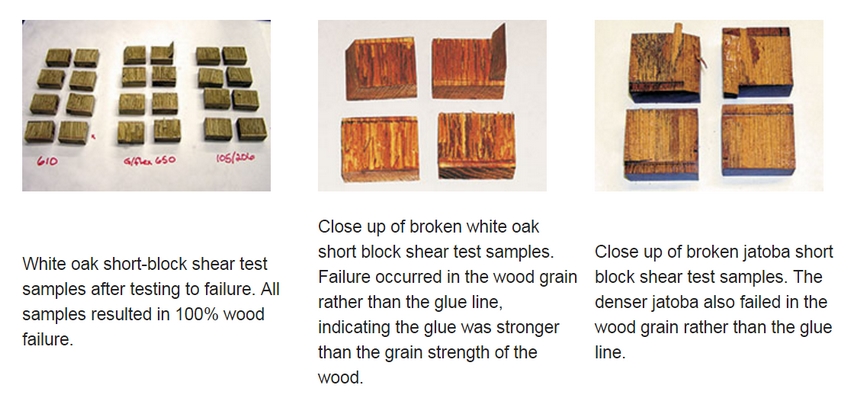

Referring to the photos (below) of the broken samples we can see that every sample in the population, regardless of which system was used, resulting in 100% wood failure. But that doesn’t mean all things are equal.

What are the practical implications we can assign to the observed results? Given that all the samples received the same prep, all of them resulted in 100% wood failure and all the values are very close, it is fair to say the glue is stronger than the shear strength of the oak. The slightly higher values achieved with G/flex can be explained by noting the extent of the wood failure. Because of the tough flexibility of G/flex, more wood got involved in resisting the applied shear force and so the value was somewhat higher.

What we learn from this test data is that, contrary to the opinions of the naysayers, with the proper surface prep white oak is quite bondable. It’s instructive to understand what these numbers really mean and how they might apply to something real, like a boat. For tensile adhesion picture this: you could lift a block of aluminum weighing just under a ton by a 1″ square piece of white oak glued to it.

An interesting point to make in that regard is the use of a wipe with an alcohol pad, a practice I am following more and more. Our current theory as to why this works is that the alcohol removes oils in the wood and the water in the wipe raises and opens the grain which allows for better penetration and therefore involves an increased amount of wood surface to better share the load. Regardless of the mechanism, the data doesn’t lie: that surface prep works well.

The results of testing we did on another dense wood from South America, jatoba, support this conclusion. The white oak we tested had a density of 10.461 g/in3 (39.9 lbs/ft3) while the jatoba had a density of 15.80 g/in3 (60.2 lbs/ft3), which is 33.7% denser than the oak. If density plays a role in adhesion we should be able to see that here. First, let’s look at the results:

| Jatoba short-block shear test results | |

| Adhesive | Average shear strength |

| 105/206 | 3,319 psi |

| G/flex 650 | 4,031 psi |

| Six10 | 4,088 psi |

Looking at the photos of the broken samples we see very similar results. Every sample has 100% wood failure and the average shear strength values are consistently similar. Again, it’s fair to say that the glue is stronger than the shear strength of the jatoba and that the higher values with the jatoba reflect the increased density and thus the increased shear strength over the oak samples.

Still not fully convinced? Good. Neither am I. As encouraging as this data is, I can’t help wondering if it accurately describes what we can expect in the real world. These samples were made in the lab under ideal conditions of moisture content, humidity, temperature, etc. How often are boats built that way? Good question. To try to answer it we are conducting another series of tests where the samples will be tortured in our environmental huts to really get that oak moving. I’ll report the results in the next issue of Epoxyworks.

Featured Image by JaneB13 on Pixabay.