by Jim Derck and Captain James R. Watson, GBI Technical Advisors

Making a hole-locating tool

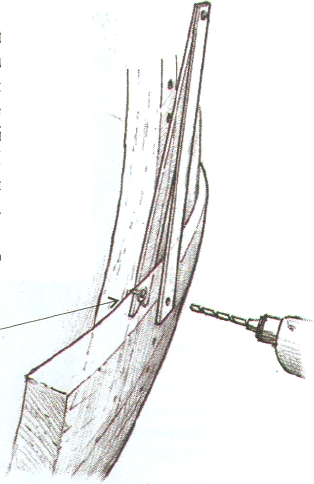

When replacing planking, often you have to drill a new hole through the wood and “hit” the existing hole on the frame (so as not to riddle the frame with new holes). This tool will help you properly locate the new hole. You can either modify a set of barbecue tongs to make this tool, or fashion one from strips of aluminum. Drill a hole in the blades. Attach a pointed stud to the lower blade.

Slip the lower blade behind the plank. Use the stud to find the existing hole in the frame. The hole in the upper blade allows you to drill through the plank in exactly the right spot.

Similarly, a V-shaped slot in the lower blade would allow you to locate a protruding bolt. —Captain James R. Watson

Making a curved-tip syringe

If your epoxy application calls for a curved tip syringe, you can easily make one by modifying a WEST SYSTEM® 807 syringe. Simply submerge the tip in boiling water for several minutes. (If you’re careful, you can also heat the tip with a match or other small heat source.) Then remove it and apply pressure to induce a curve. Hold the tip in the desired shape until the plastic cools. —Jim Derck

For sanding perfectionists

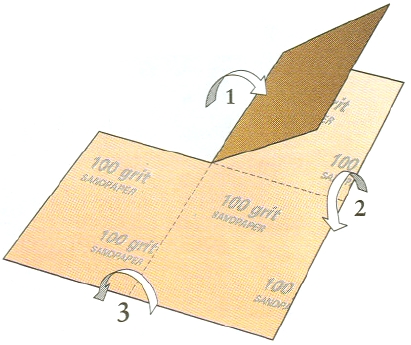

Here’s a way of folding paper for hand-sanding so that grit sides don’t rub against each other. Reverse the fold order to expose the two unused sides.