by Jim Derck—GBI Technical Advisor

It’s difficult to prevent cloth from lifting when fiberglassing around a sharp wooden corner. Even if you were able to lay glass tightly around a sharp corner, it could easily be dented. The slightest compression of the underlying wood could leave a void, and an invitation for moisture and the problems it creates. To avoid these problems, we always recommend rounding over the corner so the glass will lay flat against the surface. However, there may be times when you need a sharp corner. Here’s a method to make sharp fiberglass corners that are strong enough to prevent dents and protect the underlying wood.

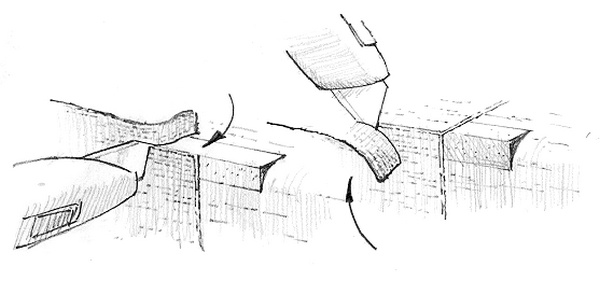

Start by cutting a chamfer on, or rounding over the corners you plan to glass. Coat the surface with epoxy, then build up the edges to their original shape with a mixture of epoxy thickened to a non-sagging consistency. When the thickened epoxy cures, sand both sides of the corner fair.

Apply the glass to each side of the corner in separate operations. Apply fiberglass cloth to the first side of the corner, letting it extend slightly past the corner. Allow it to gel. When it is at a flexible leathery stage, use a sharp utility knife to trim the material extending past the corner. Then apply the glass to the other surface in the same way. Apply the build-up coats to the glass and finish normally. The corner can be left sharp or rounded slightly with a sanding block.

Filling the corner with epoxy helps reinforce it, makes it harder to dent and will prevent water from seeping into the underlying wood if it is dented.