By Terry Monville – GBI Technical Advisor

Knowing how or why your boat’s gelcoat cracks occurred in the first place is the key to a successful repair. For example, if hitting a seawall or dropping a champagne bottle on deck is what caused the cracks, after fixing them you will know how to prevent them in the future: Don’t drink the champagne causing you to hit the seawall and drop the bottle.

Then there are those cracks that seem to appear in the gelcoat from nowhere: in cabin and cockpit corners, around screw holes, or in the middle of the deck. It can be challenging to figure out what caused them.

So, What is Gelcoat?

Gelcoat is a pigmented, high-quality polyester resin used as the finish on fiberglass boats. Like any other polyester resin, it has good points and bad. Let’s look at some of the bad points that lead to cracking.

After it’s applied, gelcoat shrinks 4 to 7 percent during the cure and can have less than 1 percent elongation. This contributes to gelcoat’s nice, hard finish, which we like, but also makes gelcoat brittle, particularly if it was applied thicker than recommended.

Gelcoat should be about 20 mils (.020 of an inch) thick when the manufacturer properly applies it to the mold. But when the builder sprays gelcoat on the mold of a boat deck with cabin top corners and seat backs, the edges tend to get more than needed. Or the gelcoat runs down and builds up in an inside corner, or too much or too little gelcoat gets sprayed on the whole mold.

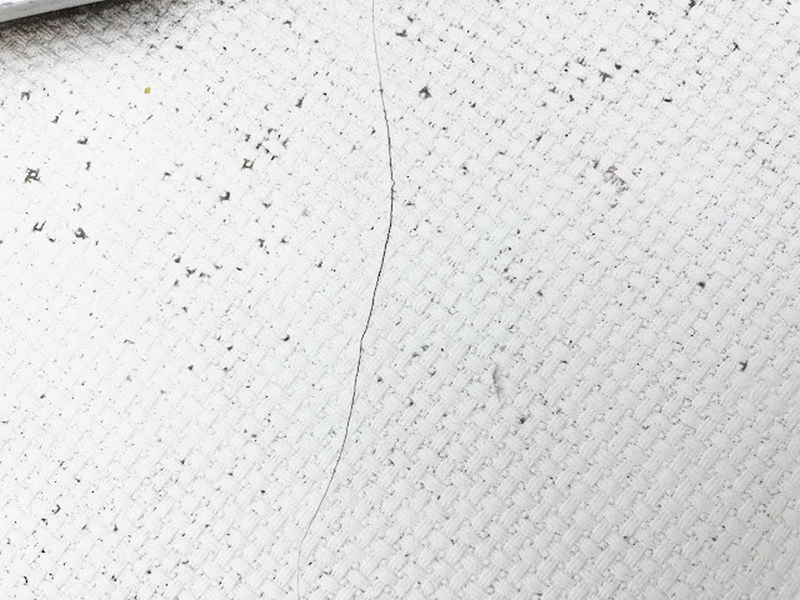

Minor Single Line Gelcoat Cracks

Thick areas of gelcoat don’t have reinforcing fabric to help hold them together. The stress is relieved in the form of a crack. This can happen when the part is pulled from the mold or years down the road, where a little more stress is introduced from the part flexing. Generally, these cracks will appear as single-line gelcoat cracks in the cabin or cockpit. This type of cracking is hard to avoid and is part of boat ownership. Luckily, the repair is simple and straightforward, as I’ll explain later.

Another common crack is a screw hole crack: a hairline crack or two coming from a piece of deck hardware. This can happen after a self-tapping or sheet metal screw is used to add a piece of hardware, even if you’ve used a proper pilot hole for the screw. The threads on the screw create pressure on the gelcoat causing it to crack. Not using a pilot hole or using one that is too small will create even more of an issue. They are often seen around snaps for canvas and beverage holders. When mounting hardware with self-tapping screws, you should drill the pilot hole and then countersink to remove the gel-coat to the threads’ diameter. This will prevent the threads from creating pressure on the gelcoat and make a small pocket for sealant to help seal the screw.

Repairing Minor Gelcoat Cracks

- Use a rotary tool or scraping tool to open the crack into a “V” shape. You will need to go through the gelcoat to the fiberglass and open the full length of the crack. Next, use 80-grit sandpaper to scuff up the opening you created. Fold the sandpaper so you can get a corner of it into the opened crack.

- After removing the dust, you can fill the crack with G/flex® 655, Six10®, or WEST SYSTEM 105 Epoxy Resin® and a choice of hardener thickened with 406 Colloidal Silica Adhesive Filler.

- After the epoxy has fully cured, wash it with water to remove any amine blush. The blush is water-soluble, which means water is the best option to remove it. You can now sand and apply a color-matching gelcoat to the area.

If the gelcoat cracks were caused by fiberglass flexing, add some fiberglass reinforcement to the backside to help prevent future cracks.

If a screw hole repair has a fiberglass core behind it, seal the core with epoxy. With balsa or foam core, use a bent nail to remove a small amount of core from behind the fiberglass, then fill the area with 105/20X thickened with 404 High-Density Adhesive Filler. For plywood or other wood core, make an oversized hole and fill it with 105/20X and 404 High-Density filler. Both methods provide a good seal on the core and more holding strength for the fasteners. For greater detail on fastener bonding, read the Fiberglass Boat Repair & Maintenance manual’s section on hardware bonding or visit westsystem.com/hardware-bonding.

Stress Cracking

A concentrated group of cracks generally running in the same direction indicates a more severe problem. This is often found on the leading edge of the cabin top where it meets the deck. This can be the result of a high flex area enduring heavy seas or too much load on the boat. Cracks may also form at a bulkhead or other hard spots behind the fiberglass when the boat flexes, creating pressure.

To repair this type of cracking, remove the gelcoat from the area and inspect the fiberglass for deeper cracks. Simply wipe the area with a wet cloth so the cracks or fractured fiberglass will appear as white lines in the laminate.

Continue until the fractured laminate is removed, then do a traditional fiberglass repair following these steps:

Grind out the area to a taper of 12 to 1 from the deepest point.

Cut fiberglass patches starting with the largest first, working your way smaller to fill the area that has been ground away.

Using WEST SYSTEM Epoxy, wet out the fiberglass pieces and apply them to the repair area, starting with the largest patch first and working your way to the smallest. Let the epoxy cure.

Wash the area with water and a nylon scrub pad to remove any amine blush, and sand the repair fair with the surrounding area. If there are low spots, thicken WEST SYSTEM Epoxy with 407 Low-Density Fairing Filler and use it as a fairing compound to fill in low areas. Let the epoxy cure, wash it, and sand it to shape.

After final fairing, apply two coats of unthickened WEST SYSTEM Epoxy to seal the repair area.

Wash and sand the cured seal coat of epoxy, then apply a topcoat of paint or gelcoat. See Fiberglass Boat Repair & Maintenance, pages 19-25 for detailed instructions.

Thermal Fatigue Gelcoat Cracks

The environment can dramatically affect gelcoat. Wax can protect it from fading, but there is no way to protect gelcoat against the repetitive expansion and contraction of temperature change. This movement can cause cracking, which may appear in a parallel or a random pattern.

Parallel patterned cracks will vary in length from short to several inches and are a few to several inches apart. I have heard them referred to as old age cracks. Often, these are caused by an expansion of the deck laminate, making the gelcoat more susceptible to flexural stress.

Short, random cracks are also referred to as gelcoat crazing. Crazing can be localized to a small area or completely cover a deck. I have seen cockpit soles that remind me of a shattered car window. Crazing is caused by the gelcoat expanding and contracting over a given area.

We get customer calls asking if sanding the gelcoat and rolling epoxy over it will fill the gelcoat cracks and prevent them from returning. Sadly, the answer is no. Cracked gelcoat should be removed. After gelcoat removal, sand the fiberglass laminate with 80-grit sandpaper. After sanding, make any needed repairs to the area. Roll on a minimum of three coats of WEST SYSTEM® Epoxy to seal the fiberglass before applying a finish coat of paint or gelcoat.

When gelcoat cracking is a symptom of another problem, repairing the crack and not repairing the underlying cause could lead to repeated cracking. In the case of a thick gelcoat, thinning the gelcoat is not practical.

After the repairs are completed, some boats remain crack-free for years. Taking your time and doing the job right will pay dividends in time and money.

Our Fiberglass Boat Repair & Maintenance manual has illustrated instructions on many aspects of fiberglass boat repair, including gelcoat repairs. It’s available for free download in the instruction section on westsystem.com.