by Tom Pawlak — GBI Technical Advisor

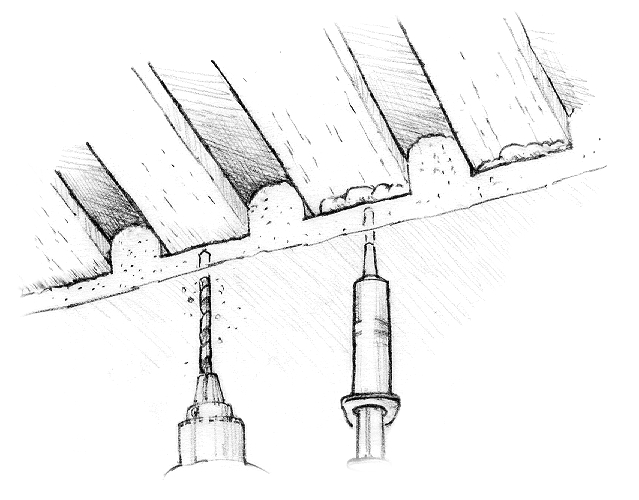

Above: Tom’s approach to repairing cracked plaster involves Drilling into the lath and injecting thickened WEST SYSTEM Epoxy.

A 100-year-old friend called in tears because her living room ceiling had cracked and she was afraid that the plaster was going to fall. I did my best to calm her and offered to come over and take a quick look.

I took my 4′ aluminum straight edge so I could determine if the plaster had pulled away from the wood lath. The straight edge revealed about 1″ of sag in one corner of the ceiling. I carefully pressed upon the plaster and verified that it had pulled away from the wood lath layer. I assured her that it could be repaired without tearing the ceiling down, then went home to get the necessary supplies for repairing cracked plaster.

My plan was to drill a series of holes through the plaster, inject some thickened epoxy into the holes, and force the plaster back into position with a plywood caul (a sheet of plywood to provide broad support) and prop sticks to hold it up, and let it cure. The repair went off without a hitch.

Steps in repairing cracked plaster

- Tape a piece of 4-mil clear plastic sheathing to the ceiling and trace the crack pattern onto the plastic.

- Remove the plastic and trace the crack pattern onto the plywood caul.

- Cut openings in the plywood, using a saber saw, at the points where the major cracks intersect. This allows you to verify if the cracks are coming together uniformly during the propping sequence (below). Tape the plastic back in position on the ceiling.

- Prop the plywood caul in place over the area. Use prop sticks cut to a length that will push and hold the loose plaster up against the lath. I used several prop sticks cut to length from scrap ¾” × 2½” lumber.

- Dry-fit the repair to verify that the plaster can be forced back into position. I used the hack saw blade to fish out a few loose chunks of plaster that had come loose that kept the plaster from getting back against the wood slats. Verify that the plaster is in position by checking the fit of the intersecting cracks. Use a hacksaw blade as a depth gauge to check how tight the plaster fits against the lath.

- Drill holes through the plywood and through the plaster, stopping short of drilling through the wood lath layer.

- Inject thickened epoxy into all of the holes—about ½ of an 807 syringe-full (±6 cc) per hole. I used 404 filler thickened to a mayonnaise viscosity because it cures with less heat (in mass) than our other fillers and because it will wet out dry surfaces.

- Realign the pieces of plaster at the cracks if necessary. The cut-out sections on the plywood caul allow you to check alignment. Adjust the prop sticks as necessary by inserting shims between the tops of the prop sticks and the plywood caul.

- Allow the epoxy to cure overnight. Remove the prop sticks, plywood caul, and plastic after an overnight cure.

I tapped all around the repair listening for dull sounds that would indicate poor adhesion. Thankfully, all of the repaired spots had a nice crisp, solid sound to them. The surrounding area beyond the drilled and filled area sounded a bit off-key, so I drilled more holes and injected a bit more epoxy into the surrounding area. I wanted to be certain that the ceiling would not come away from the wood lath in the future.

At this point in the repair, I could have proceeded with conventional patching spackle but I decided to proceed with epoxy so the repair could be finished quickly.

I used a syringe and thickened epoxy to top off all of the previously filled holes and to fill the cracks. I thickened epoxy with 410 Microlight® because the ceiling had a swirl texture which would make the cosmetic repair a bit of a challenge. 410 Microlight thickens to a smooth troweling consistency and can be carved and sanded easily, if need be, after the epoxy cures. Using a plastic spreader (that had been intentionally nicked up with a hacksaw to leave furrows and ridges), I spread the epoxy in a swirling motion, which provided a texture similar to the rest of the ceiling.

The epoxy was allowed to cure for about three hours before painting. I chose Benjamin Moore’s™ Fresh Start (100% Acrylic Latex) Interior/Exterior paint primer. Most fast-drying house paint primers (the kind that dry in 45 to 90 minutes) can be applied successfully to green epoxy (while it is still a bit soft). KILZ™, Bulls Eye™ 1-2-3 Primer/Sealer and Cover Stain™ Primer/Sealer also work well for this. An hour and a half later I applied the latex topcoat paint to finish off the repair.