By Kai Sturmann. In this article, we explore the rebirth of a classic rowing shell.

Not having any particular skills in wooden boat building or repair, I embarked on a project to resuscitate a near-derelict wooden rowing shell. Determination is a 23′, Joseph Garofalo-built, single sliding-seat wherry. While fully expecting this to be an immersive project and learning experience, my confidence to take this on was built on the expertise of friends and my faith in epoxy.

Read more: Rebirth of a Classic Rowing ShellThe hull is constructed of thin cedar plywood on oak keelson and frames built over temporary molds. In essence, a one-layer cold molded construction. Determination’s condition presented two primary challenges:

Several of the frames had rotted away at their lower ends, allowing the keelson to separate from the rest of the structure, thus deforming the hull and rendering it unstable Fig. 1.

The skin of the hull was perforated in several places, showing several unsightly and deteriorating fiberglass repairs. At the bow, the plywood skin had pulled back from the stem post.

A knowledgeable friend provided a solution to the first problem by suggesting that I fashion gussets and pull the keelson up in line utilizing throughbolts Fig. 2. Once the hull shape was restored, new frame ends were scarfed onto the existing upper frame remnants and secured using thickened WEST SYSTEM® Epoxy Fig. 3. Structural integrity was further enhanced by thickened epoxy fillets on either side of the keelson, running the full length of the boat (up to, and including, the stem and stern posts).

Having achieved integrity in the frame structure, it was time to address the problems of the hull itself. A proper wooden boat repair—restoring the hull to its original, as-built condition—was out of the question. Determination was too far gone for that. Despite that assessment, the interior of the boat (apparently somewhat protected from the elements) cleaned up extremely well. The beautiful old-growth cedar showed remarkable potential. The exterior of the boat was a different story. It was worn and weathered, and in some places, completely done. The once beautiful hull had slowly transitioned through patina to unsightly. I wanted Determination to be seaworthy and beautiful. Which way to go here? Would form follow function, or could function follow form? Epoxy allowed me to have it both ways.

Applying a layer of woven E-glass, set in epoxy, over the exterior hull was the obvious solution. This would provide structural integrity and, if painted, a satisfactory appearance. However, it occurred to me that carbon fiber was a better option aesthetically and might provide additional structural resilience.

One challenge was the upper edge of the carbon fiber sheathing which would abut the spruce sheer strake. Carbon cloth frays immediately upon cutting, so I had to find a way to create a clean edge. I had no experience with vacuum bagging but felt that it might be successful in forcing the saturated carbon fiber to conform to that concave edge. Once the epoxy set, the excess cloth could then be trimmed in a clean line Fig. 4.

I fashioned a vacuum pump apparatus utilizing a medical ventilator pump that had exceeded its certified lifespan (Gast model 0870) Fig. 5. Materials were sourced from Jamestown Distributors, Fibre Glast Developments, and Composite Envisions, utilizing WEST SYSTEM products exclusively, whenever available.

The interior and exterior of the hull were stripped and sanded to bare wood. Any existing fiberglass patches were removed, and work began on the interior surfaces.

Perforations and large cracks were filled with a thickened epoxy mixture. Once faired and sanded, these areas were covered with a thin layer of cedar veneer bonded with epoxy under vacuum pressure Fig. 6. This worked well, allowing me to get used to the vacuum pump and assorted materials. I placed two layers of 4 oz. woven E-glass into clear epoxy on the lowest section of the bilge as reinforcement for a pair of suction bailers Fig. 7 & 8.

The outside surface was prepped, and the defects were filled with thickened epoxy. I added additional longitudinal stability with a single layer of 6″ unidirectional carbon tape running the length of the boat along the centerline below the keelson Fig. 9. At this point, timing and scheduling became critical. The intent was to ensure chemical bonding between the various layers applied.

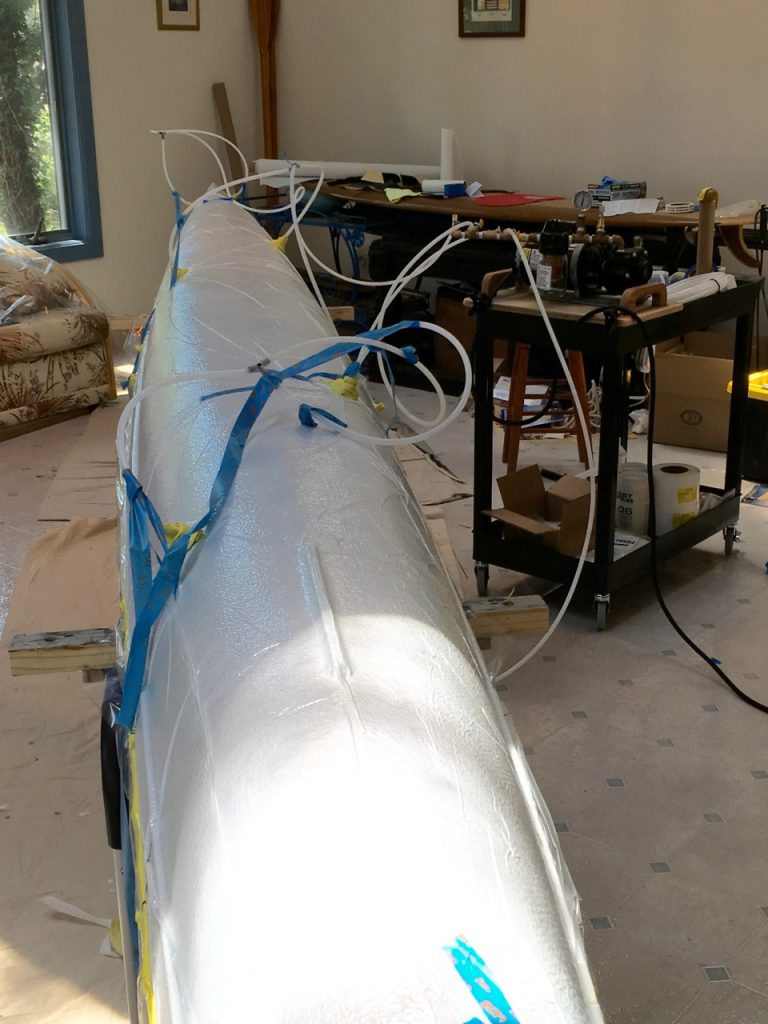

Lay-up began by wetting out the hull with a black-pigmented epoxy saturation coat. This was done to prevent the wooden surface from showing through the carbon fiber. Once this became tacky, 4 oz. carbon fiber twill weave cloth was rolled out over the hull, draped into place, and trimmed. This was quickly wet out with clear epoxy (WEST SYSTEM 105 Epoxy Resin®/207 Special Clear Hardener®). The epoxy was followed by the application of release fabric, breather fabric, and the vacuum bag film. Sealant tape along the edges made the vacuum bag film air-tight and appropriate hose connections were made, before applying the vacuum pressure at (-)15mm Hg. Fig. 10.

Once the epoxy had cured, the vacuum apparatus was peeled away, and the carbon cloth was trimmed. A hot coat of clear epoxy was then applied and allowed to cure. The finished surface was surprisingly fair and required minimal sanding. The final stage was application of Epifanes® Poly-urethane Clear Satin for UV protection.

Shrink-wrapping tape was used to prevent epoxy from contacting the wooden surfaces not intended for the carbon sheathe. This worked well; there was no bleed through the tape and excess was easily removed leaving a smooth surface and clean lines Fig. 11. The interior and sheerstrakes were finished with five coats of Epifanes Clear Varnish.

I’m pleased with the results. To my knowledge, this approach has not been reported before. It lends itself well to repairing and restoring other light rowing or sailing craft. Working with the epoxy in a temperature-controlled environment was predictable and straightforward. I’m grateful for the assistance provided by my brother and friends.

One day after the initial launching, Determination completed the 20-mile open-water Great Peconic Race. She successfully competed in the Head of the Charles Regatta (2022) Fig. 12.

Explore more Boat Repair Articles.

Fore more techniques and information, download WEST SYSTEM’s Wooden Boat Restoration & Repair Manual for FREE!