Jim Brown built this strip canoe in his New Hampshire garage. He used mostly cedar strips with some white pine and IPE on the gunnals. Using WEST SYSTEM® 105/207, he applied two layers of 6 oz. fiberglass to the bottom of his canoe and one layer to the inside.

Ice Cream Cone Sculpture – George Abrams

After selling his Core Sound 17, George Abrams switched to art. He mostly does his art for fun, coming up with some creative projects including this ice cream cone sculpture. These sculptures were built out of carbon fiber and fiberglass using WEST SYSTEM® 105/205 and 105/207.

Engine Hatch Mod – Gary Barg

Gary Barg has a 2000 Tiara Express 40 boat that had a power uplift table that stored in the engine hatch tub. It was high maintenance. It collected enormous amounts of dirt and bugs. Keeping it clean was always an issue. One fall, he and his wife had it. They pulled out all the mechanisms, stainless steel scissor lifts, hydraulic motors, lead screws, etc. They unfastened the engine hatch and loaded it into their pick-up with the aid of their dock neighbors.

Ice Cream Cone Sculpture – George Abrams

After selling his Core Sound 17, George Abrams switched to art. He mostly does his art for fun, coming up with some creative projects including this ice cream cone sculpture. These sculptures were built out of carbon fiber and fiberglass using WEST SYSTEM® 105/205 and 105/207.

Engine Hatch Mod – Gary Barg

Gary Barg has a 2000 Tiara Express 40 boat that had a power uplift table that stored in the engine hatch tub. It was high maintenance. It collected enormous amounts of dirt and bugs. Keeping it clean was always an issue. One fall, he and his wife had it. They pulled out all the mechanisms, stainless steel scissor lifts, hydraulic motors, lead screws, etc. They unfastened the engine hatch and loaded it into their pick-up with the aid of their dock neighbors.

The project moved to their home basement for the winter. They cut the fiberglass tub bottom out and left just enough lip to float the table top flush with the boat deck. They also fabricated a bottom to support the new deck. They used extruded aluminum angle, ¾” plywood and Six10® Thickened Epoxy Adhesive. They attached four jack screws to the bottom of each panel to level them to the existing top deck.

With the advice of the WEST SYSTEM® Technical Advisors, They did three pours of 105 Epoxy Resin® with 206 Slow Hardener®. For the first pour they weighed the four panels down with paint cans to prevent the panels from floating up. For the last pour the Technical Advisors suggested to add filler for softness if any sanding would be required. There was no sanding required. The final pour flowed beautifully. In total, they poured about three gallons of epoxy.

After the gelcoat was complete, the hatch looked like it came straight from the factory. They added insulation on the underside. With the above changes, They added about 10 inches of head room in the engine room.

The project moved to their home basement for the winter. They cut the fiberglass tub bottom out and left just enough lip to float the table top flush with the boat deck. They also fabricated a bottom to support the new deck. They used extruded aluminum angle, ¾” plywood and Six10® Thickened Epoxy Adhesive. They attached four jack screws to the bottom of each panel to level them to the existing top deck.

With the advice of the WEST SYSTEM® Technical Advisors, They did three pours of 105 Epoxy Resin® with 206 Slow Hardener®. For the first pour they weighed the four panels down with paint cans to prevent the panels from floating up. For the last pour the Technical Advisors suggested to add filler for softness if any sanding would be required. There was no sanding required. The final pour flowed beautifully. In total, they poured about three gallons of epoxy.

After the gelcoat was complete, the hatch looked like it came straight from the factory. They added insulation on the underside. With the above changes, They added about 10 inches of head room in the engine room.

Teardrop Camper – Bill Lawson

This 5’x10′ teardrop camper was designed and built by Bill Lawson. He wanted a camper that could transport his ILCA dinghy to regattas and would be comfortable to stay in for the duration of the event. This year alone, he’s taken it to regattas all the way from Florida to Nova Scotia. The trailer was built with Okume plywood, WEST SYSTEM® 6 oz. fiberglass cloth, and 105/207. The interior cabinetry is cherry and birch. The roof racks are Ipe. He has enough battery to go off grid for four days and takes four hours to recharge while towing.

Trebuchet – Bob Garrison

One of Bob Garrison’s past build projects was a trebuchet. An integral part of the design was that the trebuchet could be moved by three people, a pickup truck, and a tractor. This way it could be assembled for the main entertainment at his big annual cookout in September.

The trebuchet was built using mostly 2×6 lumber and WEST SYSTEM® 105 Epoxy Resin® with 206 Slow Hardener®. The round counter weight and the four anchor blocks were made of poured concrete. Machinery was needed to move these. It took about a day to get it assembled or disassembled for storage.

Trebuchet – Bob Garrison

One of Bob Garrison’s past build projects was a trebuchet. An integral part of the design was that the trebuchet could be moved by three people, a pickup truck, and a tractor. This way it could be assembled for the main entertainment at his big annual cookout in September.

The trebuchet was built using mostly 2×6 lumber and WEST SYSTEM® 105 Epoxy Resin® with 206 Slow Hardener®. The round counter weight and the four anchor blocks were made of poured concrete. Machinery was needed to move these. It took about a day to get it assembled or disassembled for storage.

Cedar Kite-Flying Man – Robert Crowell

15 years ago, Robert Crowell built a cedar kite-flying man sculpture for Kitty Hawk Kites, on the Outer Banks of North Carolina. Twelve boards were laminated together with WEST SYSTEM® Epoxy to form the sculpture. It was finished with epoxy and topped with coats of Captain’s Varnish. After visiting recently, he was pleased to see what good shape it was in, since the weather there can be very harsh. “As expected, after 15 years, the finish is practically gone but the laminated boards are holding well. A true test of your product!”

This sculpture was initially featured as a reader project in Epoxyworks 25 back in the summer of 2007.

15 years ago, Robert Crowell built a cedar kite-flying man sculpture for Kitty Hawk Kites, on the Outer Banks of North Carolina. Twelve boards were laminated together with WEST SYSTEM® Epoxy to form the sculpture. It was finished with epoxy and topped with coats of Captain’s Varnish. After visiting recently, he was pleased to see what good shape it was in, since the weather there can be very harsh. “As expected, after 15 years, the finish is practically gone but the laminated boards are holding well. A true test of your product!”

This sculpture was initially featured as a reader project in Epoxyworks 25 back in the summer of 2007.

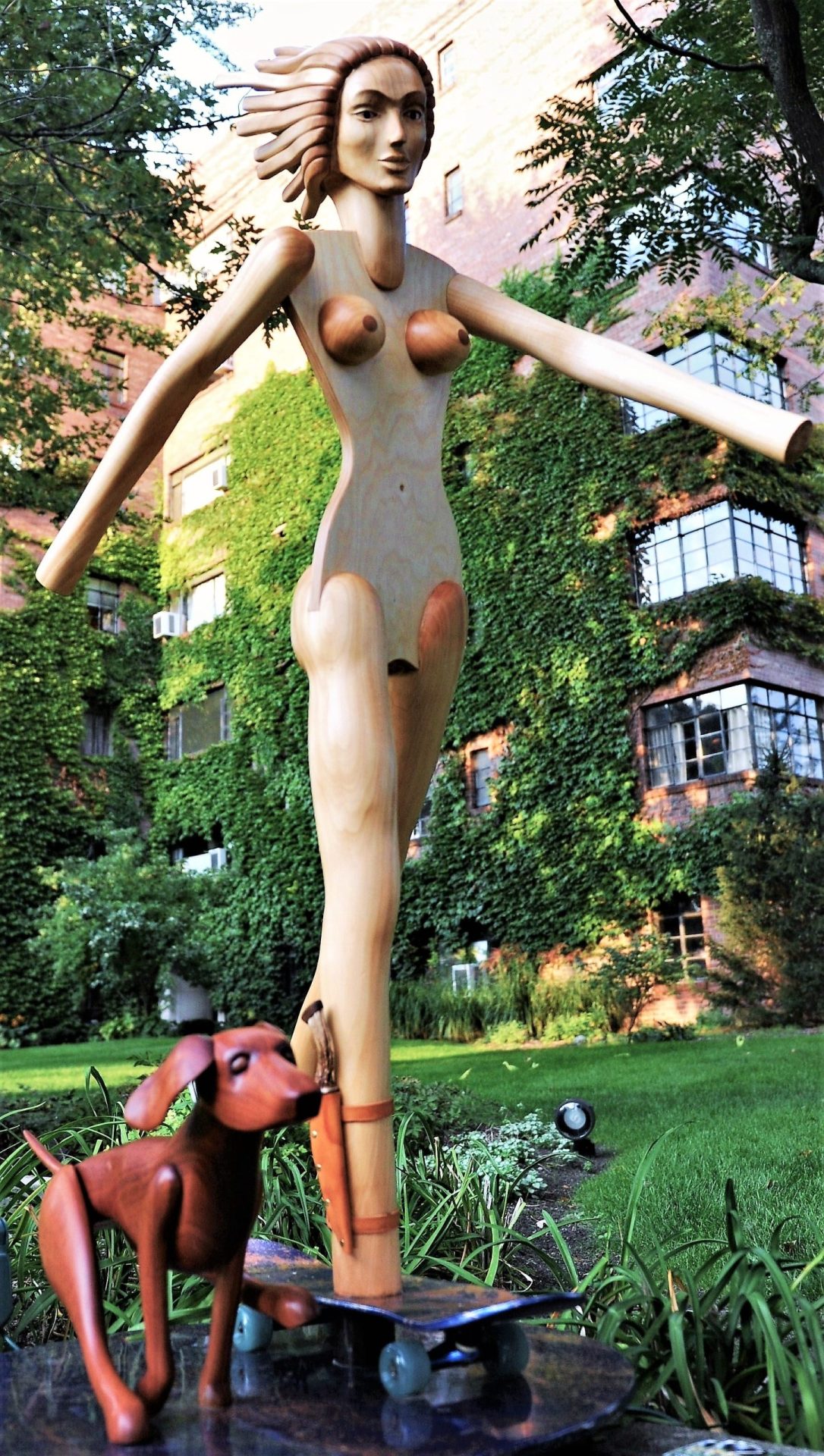

Diana & Hound – Chuck Mack

Diana & Hound is an interpretation of Diana the Huntress from Greek Mythology. The sculpture was coated with WEST SYSTEM® Epoxy for short-term outdoor exhibiting. The sculpture has been exhibited in many locations throughout Michigan—Art Prize in Grand Rapids, Art Rapids in Elk Rapids, and currently in Traverse City. To view more of Chuck Mack’s work, visit chuckmackdesign.com.

12′ Canoe & 13′ Kayak – Jon Bauer

Jon Bauer built two boats with WEST SYSTEM® Epoxy. He says, “I found this product very easy to use and it resulted in a professional finish.”

First up is his stunning lapstrake craft 12′ canoe, which was completed back in 2016. In 2022 he completed his last boat, a 13′ kayak.

12′ Canoe & 13′ Kayak – Jon Bauer

Jon Bauer built two boats with WEST SYSTEM® Epoxy. He says, “I found this product very easy to use and it resulted in a professional finish.”

First up is his stunning lapstrake craft 12′ canoe, which was completed back in 2016. In 2022 he completed his last boat, a 13′ kayak.