By Bruce Niederer — GBI Technical Advisor

My article, White Oak Redux (Epoxyworks 34), generated two responses we wanted to share. We consider ourselves students as well as tech advisors and so we’re always open to learning something from others. Our readers are generally pretty savvy people, and when they take the time to write us a thoughtful letter, we feel compelled to share what we learn from them with the rest of our readers.

Dear Editor,

Let me briefly comment on White Oak Redux in Epoxyworks 34.

The explanation given for the higher shear strength of the solid oak samples vs. the glued oak samples based on imagining longer shear lines in the solid wood does not hold up under critical scrutiny. One could imagine similar “long” shear lines in the glued samples.

A more plausible explanation: Think of a glued sample as a 3-ply block consisting of a thick ply of wood, then a thin, but finite ply of epoxy-infused wood, and another ply of thick wood. Plain wood and epoxy-infused wood obviously have different properties, in particular, they have different shear moduli. The magnitudes of the two moduli are unimportant in themselves; what matters is that they are different. Since the three plies are exposed to the same load and have equal shear areas, the shear stress in each is the same, but the shear strains are not on account of the different moduli. On the ply boundaries, the shear strains will jump from one value to a different value, creating a high strain gradient at this point. High strain gradients are failure initiators. This predicts failure in the wood part of the glued sample in the area of high strain gradient at a smaller load compared to the failure load for the same wood in the absence of a high strain gradient. In short, plain wood is stronger.

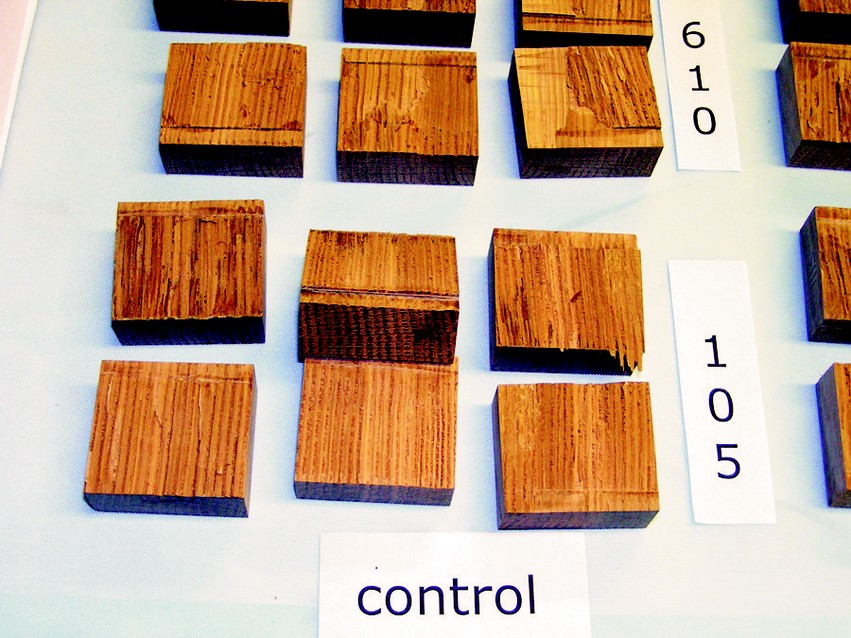

Looking at the somewhat vague pictures of failed blocks in the article, it does appear the above hypothesis is confirmed. The failures occur in the wood on planes more or less parallel to and close to the glue surfaces, namely where the strain gradient is high.

Very truly,

Ralph Koebke

St. Augustine, Florida

Dear Mr. Koebke,

Thank you for taking the time to write your very insightful letter in response to my article White Oak Redux. Although you didn’t mention your background or experience, we all surmised you must have some sort of engineering or science background. Many of our customers are very savvy builders with various levels of experience and training, but we don’t often receive letters that reveal the level of understanding and sophistication we found in your comments.

We, of course, know that all things being equal, the solid wood will outperform a glued sample in shear. But in practice, all things aren’t equal. Large parts of solid white oak can be very dimensionally unstable. It will change along its width and length plus it can twist with changes in moisture content. Coating the oak can help stabilize the moisture transmission and so too the dimensional instability, but we’ve known of many instances where the movement in the solid wood cracks the epoxy, which can allow moisture to intrude behind the coating. The resulting trapped moisture becomes a breeding ground for rot formation. For that reason, we promote using WEST SYSTEM® Epoxy to laminate thin strips of oak to build the necessary thickness for the part because it relieves much of the linear stresses found in solid wood parts. Alternating grain orientation in the laminate stack is a very effective way to accomplish building a stable oak part of nearly any size.

The ongoing controversy in the wooden boat building community is that there are a large number of “purists” who believe oak cannot be glued effectively with epoxy. The point of this follow-up article as well as the first article was to conclusively prove white oak can indeed be bonded using epoxy even and especially in highly loaded applications like stems, frames, and scarf joints. We felt that tensile adhesion did not tell a complete story and so we initiated the short block shear study and included the environmental cycling to torture the wood and glue lines to mimic a more realistic situation. Our goal was to do our best to dispel these deeply entrenched myths regarding epoxy adhesion to white oak.

I was looking at the differences in shear values between solid and glued shear samples from the solid block side because the failed samples were very interesting. In the aftermath of the test, the wood fibers that ran through the shear plane as described in the article were tenacious even after 6 weeks of cycling from saturated to dry. I had to force the two halves apart with a pry bar. I misspoke myself in the article by saying “As shown is this diagram, each solid oak sample has grain that passes through the straight-line shear plane. This grain structure, not present in any of the glued samples, effectively increases the area of the shear plane which results in a higher value.” Obviously, the shear plane is a set dimension regardless of grain orientation so the area doesn’t change. What I should have said is “This grain structure, not present in any of the glued samples, effectively increases the relative strength of the block which results in a higher shear value.”

That said, we believe your explanation is much more nuanced and provides a better and more technical explanation. You have provided our readership a more complete understanding of the science behind epoxy glued oak joints in this shear test and by extension, in boat building applications.

Thanks again for taking the time to write us.

Regards,

Bruce Niederer

Senior Tech Advisor/Chemist

Hi,

I have been a subscriber of your free Epoxyworks publication for many years and I still like it very much.

I used often WEST SYSTEM 105. In Epoxyworks 34, Spring 2012 I do not understand why they say in White Oak Redux just before the conclusion that “3M 5200 …cannot be used below the water line.” Here is the description from 3M: “3M™ Marine Adhesive/Sealant 5200 is a one-part polyurethane that chemically reacts with moisture to deliver strong, flexible bonds. It has excellent adhesion to wood, gelcoat, and fiberglass. It forms a watertight, weather-resistant seal on joints and boat hardware, above and below the waterline. In addition, its flexibility allows for the dissipation of stress caused by shock, vibration, swelling or shrinking.”

We use it on many boats and everything seems to be fine between the hull and the keel. Am I wrong?

Claude,

Quebec, Canada

Dear Claude,

You are absolutely correct about the product description by 3M regarding 5200. I based my comment on the fact that I had a through-hull transducer that was mounted using 3M 5200 which began allowing water to seep through and find its way to the bilge. When I pulled the fitting to repair it, what I found was that the 5200 was basically disintegrating. I was able to push the transducer out by hand. To say the least, I was not favorably impressed.

Regardless, I know that many people routinely use 3M 5200 below the waterline in many applications, for instance, to restore classic Chris Crafts and Hacker Crafts. Don Dannenberg is an outspoken proponent of this technique. Some of the boats he’s restored are kept at docks and not trailered, and we have not heard of any wholesale failure of the 5200 from these folks.

That said, I will retract my comments here and the online version will be edited such that the comment is removed. I should have kept my personal prejudices to myself.

I still won’t use 5200 below the waterline on my boat, but I never argue with success. You should not let my comments give you cause for concern on any project you used the product for.

Please accept my apology and best regards,

Bruce Niederer

Senior Tech Advisor/Chemist

I’d like to thank both gentlemen for taking their valuable time to write us their letters, and for giving us permission to reprint their letters. Although I can’t promise every letter to the Editor will get printed, I encourage all of our readers to contact us with questions or comments. We will always answer you, regardless of whether we publish your note in Epoxyworks.