by Captain James R. Watson

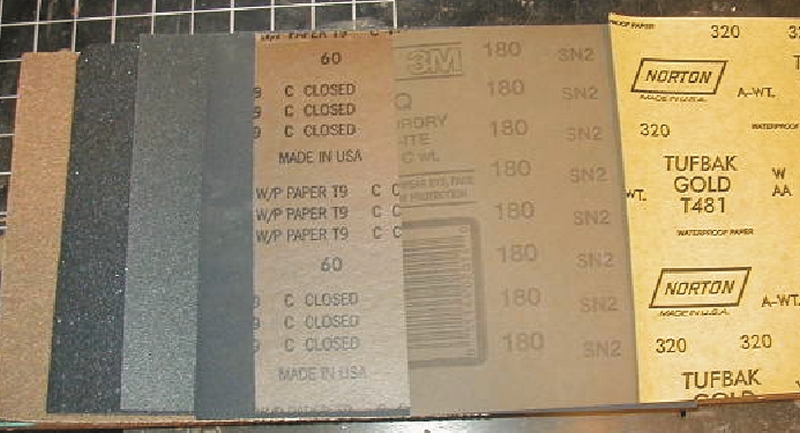

Above: For wet sanding epoxy, a typical grit sequence for smoothing an already flat surface would be 80 or 100 grit, then 150 or 180 grit, and finally 220 grit.

Wet sanding with waterproof sandpaper is often the best approach to sanding cured epoxy. Wet sanding epoxy emoves any amine blush while you sand, reduces clogging of the sandpaper, and reduces dust and exposure to partially cured epoxy. It lets your sandpaper go farther and provides a visual clue that everything is properly sanded. However, when working with bare wood or wood that cannot get wet, you will need to dry sand.

Cured epoxy is difficult to sand because of its hardness. In fact, cured epoxy is just softer than plastic laminate such as Formica® At 70°F, WEST SYSTEM® Epoxy cures to 90% of maximum physical properties within 24 hours. Epoxy cuts easiest after 24 hours of cure, but before 48 hours or more: it has cured enough to be cut, but has not reached full mechanical properties. Epoxy’s hardness dulls sandpaper fast. In addition, cured epoxy can quickly fill sandpaper, rendering it ineffective after several swipes. That’s because the very outer layer of epoxy can form an amine blush, the result of a reaction with moisture in the air as it cures.

Advantages of Wet Sanding Epoxy

Wet sanding epoxy removes amine blush

All room temperature cure amine-base hardening epoxies are susceptible to amine blush to some degree. This amine blush is soft and can be a little greasy or gooey; it doesn’t cut, but clogs or balls up so you can go through a lot of paper with little progress. (When epoxy balls up it’s an indicator that the epoxy isn’t fully cured.) Amine blush should be removed to prevent interference with subsequent coats of epoxy, paint, or varnish.

Washing with water is effective for blush removal, but wet sanding is far more efficient for large areas.

Wet sanding epoxy improves performance

Water improves cutting performance by flushing cut material from the surface that can come between the abrasive surface and the substrate. In addition, water keeps the abrasive surface clear of debris so it doesn’t clog the abrasive surface.

Wet sanding epoxy reduces dust

Because cut particles are wet when sanded, wet sanding virtually eliminates airborne dust. This reduces exposure to partially cured epoxy dust and thus is safer from a health and safety standpoint.

Waterproof Sandpaper

Waterproof sandpaper is usually a closed coat, silicon carbide. It’s available from most automotive paint and supply stores. Grits from 60 to 1000 are available, although you should only need 60 to 80 grit for initial abrasion, and 180 to 220 grit or maybe 320 for final sanding prior to priming or varnish. If your cured epoxy has runs and irregularities, I suggest starting with 60 or 80 grit sandpaper. Work your way up until you get the degree of finish you’re after.

Wet Sanding Epoxy—Tips

Wet sanding is normally done by hand. Never use an electric-powered sander when wet sanding or you could get electrocuted. We have used air-powered dual action (DA) machines for wet sanding (which is messy), but we usually sand by hand.

I use a hard rubber sanding block like the one in the photo to hold the paper when smoothing and abrading most surfaces. A curved or soft pad may be necessary on curved surfaces, but you can wet sand without a block or pad by simply folding the cloth to fit your hand and dipping the paper in water. On heavily irregular or textured surfaces such as a sculpture, the waterproof paper won’t contour enough, so use an abrasive pad like 3M Scotch Brite® with water.

I usually put water in a bucket. If the shop is cool, I’ll put hot water in a cooler (it holds heat as well as cold) to help keep it warm. I dip the rubber sanding block with sandpaper attached into the water when more water is needed. Another approach is to fill a squirt bottle and spray the substrate as you’re sanding.

Use a window squeegee to scrape excess water and cut material from the substrate so you can visually inspect the surface better. When wet, the surface is shiny, but when squeegeed, it appears dull and highlights the surface texture. When wet sanding, especially with aggressive grits, you have to keep an eye on your progress. Rinse and squeegee away water between changes in grit to avoid contaminating the finer grit with the previous coarser grit. Be sure to remove any remaining debris right after wet sanding because it’s hard to remove after it dries. Rinse water should sheet evenly, without beading or fish eyeing. If rinse water beads up, wet sand again until the beading is eliminated.

To prepare the surface for subsequent epoxy coats or painting, wipe the dry surface with a paper towel to loosen any remaining debris and then sweep it with a bench brush. Don’t use rags—they may contaminate the surface. Follow with an electrostatic dust cloth, such as a Pledge Grab-it®. We use a tack cloth prior to painting, but not for subsequent epoxy coats because the tack cloth is resinous saturated cheesecloth which can contaminate the substrate and interfere with epoxy adhesion.

Constant immersion in water softens your skin and makes your hands more susceptible to cuts and abrasions. Wet dry cycles can also result in chapped skin. Use a dry skin cream such as Pond’s® to combat this problem. If you wet sand with the paper in direct contact with your skin, it’s possible to abrade your skin away. I’ve been without fingerprints for a few days as a result. The upshot is, your hands will be cleaner than they’ve been in years, possibly with fingers a safecracker would envy.

Wet sanding can make a mess. All the cut debris in the solution with water ends up on the floor. This is difficult to sweep up when dry. But the advantage, as mentioned before, is that wet sanding produces no dust.

Much of the quality of a final finish is in surface preparation. Wet sanding eases the task without sacrificing quality.