Tips for mixing small batches of epoxy

By Tom Pawlak — GBI Technical Advisor

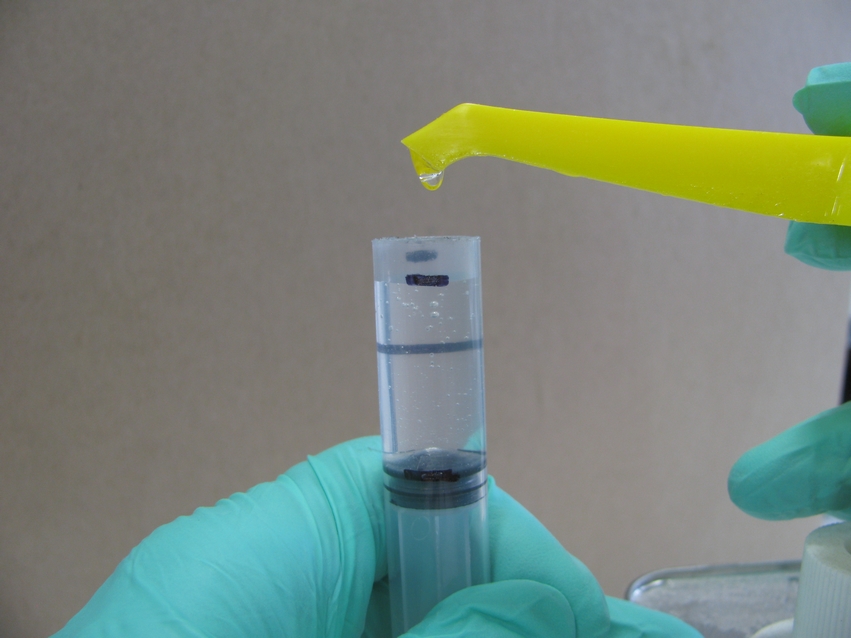

My favorite way to mix small batches of WEST SYSTEM® Epoxy, when less than full pump strokes on the mini pumps are required, is by metering resin and hardener into a graduated cylinder made with a plastic syringe. The 807 Plastic Syringes, in our product line, can be modified for this by cutting off the end of the syringe body so it looks like the end of a clear piece of plastic tubing.

For the 5:1 mix ratio needed for 105 Resin and 205 Fast Hardener or 206 Slow Hardener, you’ll need to measure ¼” back from the cut off end of the syringe body and make anindelible mark. From this ¼” mark, measure back 1-1/4″ and put another indelible mark. Now pull the syringe plunger down to the 1-1/4″ mark and fill the syringe with 105 Resin to the ¼” mark (using the mini pump to fill to the line exactly). Now top off the syringe with 205 or 206 Hardener dispensed from the hardener pump. Press the syringe plunger forward to dispense all the resin/hardener into a mixing cup and swipe the plunger tip clean along the lip of your mixing pot. The syringe can now be stored after wiping with dry paper towel for future use because all of the hardener was washed away with resin. Stir the resin/hardener mix in confidence knowing that you’ve measured exact quantities of resin and hardener.

If still smaller batches are needed, mark up the opposite side of the modified syringe with a 1/8″ mark and a 5/8″ mark and use your pumps to conveniently fill the syringe to the marks.

If you are working with 105 Resin and 207 Special Clear or 209 Extra Slow hardener, another syringe can be modified with the 3:1 by volume ratio with an indelible mark that is ¼” back from the cut off end and from this mark measure back ¾” and place another mark. This will yield the 3:1 by volume required for 105/207 or for 105/209.

Another approach to mixing accurate small batches of epoxy is to use inexpensive gram scales. These small scales allow you to mix up to 600 grams of epoxy at a time. This equates to about a pint of epoxy.

The appropriate mix ratio for our 105 Resin and 205 Fast or 206 Slow Hardener by weight is 5:1. Our 105 Resin and 207 Special Clear mix ratio is 3.7:1 by weight. 105 Resin cured with 209 Extra Slow Hardener is mixed at 3.6:1 by weight. These small gram scales have a tare feature that makes it easy to zero the scale after the initial cup tare and after weighing the first component.

Once your mixing cup is on the platen and the scale is tared to ZERO we prefer weighing the hardener first. We do this because accuracy on the hardener amount is more critical than the resin. In other words, because the amount of resin isn’t as critical as the amount of hardener, you have a bit of room for error. So if you overshoot the amount of resin by a bit it’s not a big deal but if you measured resin first and then you overshot your hardener you are more likely to be off-ratio. By starting with the hardener, the calculation for the resin amount is based on an exact weight of hardener.

These electronic scales, especially the battery-operated types, have an auto-off feature to save batteries. Be careful to touch the platen periodically so the scale does not shut off from inactivity.

Another excellent way to meter small batches of epoxy is to use Six-10 Adhesive. This adhesive is packaged (resin and hardener) in a standard size caulk tube and can be dispensed one click at a time from the caulking gun.

G/flex Epoxy 650 and 655 with its 1:1 by volume ratio is also convenient for making very small batches of epoxy.