By Jon Fox

For the past two years, the Drafting/Pre-Engineering autobody class I teach at Tuscola Technology Center in Caro, Michigan has been invited to participate in a contest sponsored by Summit Racing. Students build a custom pedal car that is displayed and judged at the AutoRAMA show at Cobo Hall in Detroit. Summit Racing either supplies participating schools with one of their stock pedal cars which can be modified and customized, or students may build their entry from scratch. We constructed our entry from scratch both years. Our first car was inspired by the Delehaye roadster and built of aluminum in an Art Deco style.

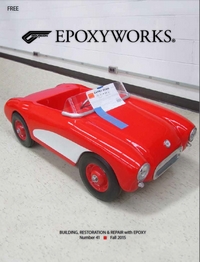

This year we made our car look like a 1957 Corvette and constructed it from composite. We initiated our design by drawing the wheels full size and in their accurate wheelbase positioning. We then downloaded and printed every 1957 Corvette profile image we could find online and sketched the shape proportionally on the wheelbase layout. Once sufficiently refined, the sketch was converted to measurable geometry and drawn in CAD in multiple 2D (orthographic) views.

Full-size CAD drawings were generated and used as patterns for shaping a glued-up rigid foam plug. We carefully shaped and detailed the plug, then layered it with WEST SYSTEM 105 Resin/205 Fast Hardener and a mix of donated and scavenged fiberglass cloth. Initially, the idea was to build a multi-section mold from the plug, but we only had two and a half months so time constraints made it necessary to construct the final body on the plug. When the layup was complete we melted the foam out with acetone. We covered the body shell with gelcoat made of resin thickened with silica micro-balloons and gray pigment, then sent it to the Tech Center’s auto body class for final surface refining and paint.

With the body sent to be finished, we turned our concentration to the mechanical aspects of the car. While a ’57 Vette would have had independent suspension on the front and a traditional straight drive axle on the rear, four-wheel independent suspension would become a trademark on future models. Our custom pedal car would have independent suspension all around so we designed front and rear cradle assemblies which housed control arms and spindles. The front features fabricated ball joints and shocks. The rear incorporates articulated axle shafts that move with the suspension. Suspension geometry keeps both front and rear wheels vertical through 2” of travel. Nearly all suspension parts were hand fabricated out of aluminum sheet. Control arms were fabricated on hammer forms and welded together.

Additional features include working head, tail and front marker lights compliments of our electronics class. They also added a pair of speakers and an MP3 player. A student designed and etched a printed circuit board and added components to build a power supply and amplifier. Headlight lenses were made by cutting flat plexiglass then heating and forming them over the end of a round metal shaping hammer.

The Corvette has competed at AutoRAMA and both Regional and State MITES conventions. It received third place at AutoRama and first both times at MITES. It represents a huge effort by students from four Tech Center programs and hands-on experience in a broad range of technical specialties. Few students will ever be exposed to a project so broad and technical in nature.

My class was always blessed by the stewardship of people like Tom Pawlak and Joe Parker (now retired) of Gougeon Brothers, who has been on our advisory committee for many years and who has been a regular guest speaker in the classroom. We’re grateful to everyone at Gougeon who has helped us.