A MiniMax Hydroplane

By Jeffrey Carpenter

In late 2018, my son and I were given a unique opportunity by the Michigan-based Water Wonderland Chapter of the Antique and Classic Boat Society (ACBS) to build an 8′ MiniMax hydroplane based on original plans from the early 1960s. Almost anything from that era seems to be popular again. Maybe it’s nostalgia or maybe the designs of that groundbreaking decade were just ahead of their time. Either way, the MiniMax’s appeal seems as relevant today as it did in 1962. We accepted the challenge without hesitation.

The youth-centric building project commenced in February 2019 at the Grand Rapids, Michigan Boat Show. We were in front of a live audience, and ACBS members generously donated wood and fasteners. Sons and daughters participated and even younger siblings got involved. Those initial marathon building sessions were the start of a nearly seven-month journey to complete our boats.

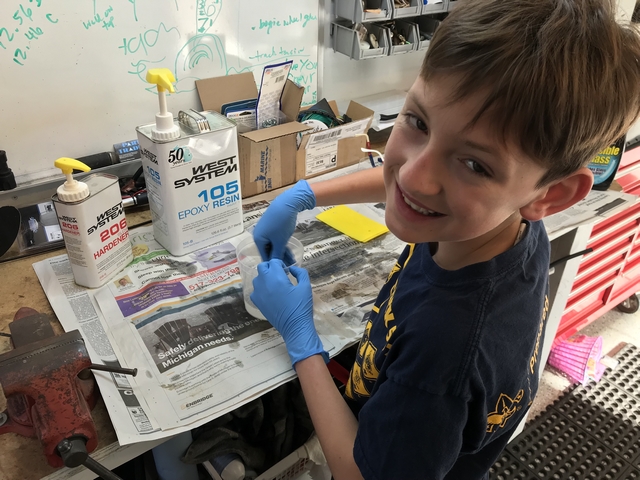

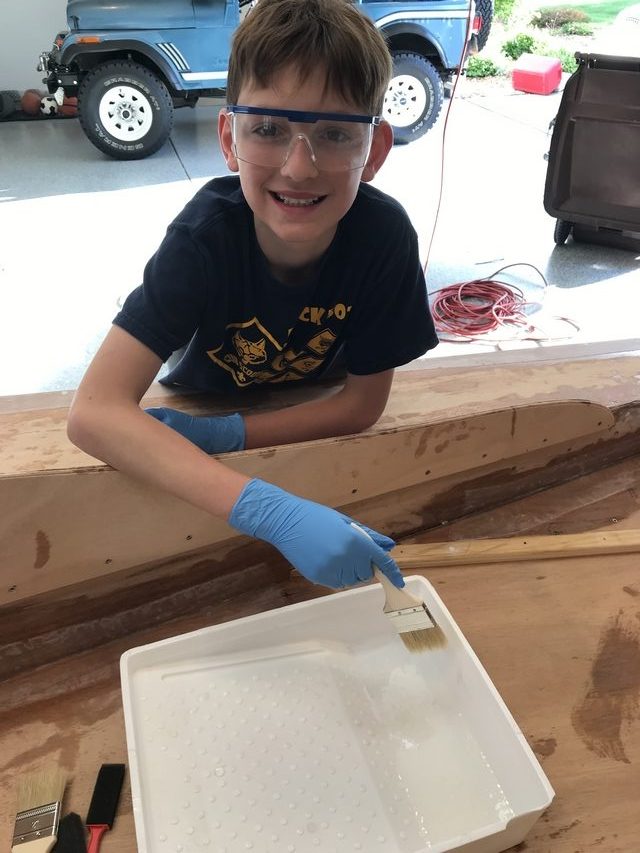

Joshua and I wanted this boat to last for generations and knew that the most effective defense against deterioration was to encapsulate the structure in a waterproof coating. We were both new to boat building and restoration. The volunteer advisors from ACBS, many with a lifetime of experience, suggested WEST SYSTEM® 105 Resin and 205 Fast or 206 Slow Hardener to waterproof our hydroplane.

As fabrication moved forward we found many practical uses for epoxy: sealing the flotation compartments, applying fiberglass cloth to the bottom of the hull and critical seams, adding strength to the transom, and ensuring that every square inch of the boat was waterproof. If you have not experienced a small hydroplane it must be stated that you need a swimsuit and a positive attitude as you will get wet. It’s all part of the fun.

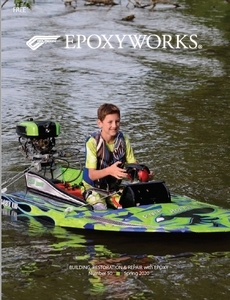

I have always wanted to try out the process of vinyl wrapping and decided this would be the perfect test case. We selected Edgewraps of Ashley, Michigan and Joshua worked with the staff to design his own custom wrap. The styling is quintessentially 11-year-old boy–lime green, blue, black, and chrome with plenty of hot-rod inspired flames. It’s named River Hornet.

Will this boat stand the test of time? Absolutely. The epoxy served as a perfect base for the wrapping process after wet sanding with 220-grit to ensure smooth vinyl adhesion. Under the three coats of epoxy is plenty of fiberglass reinforcement and a lot of sweat equity—perfect for a youth-centered project. Our MiniMax is rigged with period-correct controls, many from Portage Bay Systems of Seattle, Washington, and a restored 1956 Sea King 12hp outboard (manufactured by the Gale division of OMC) that Joshua helped tear down and re-assemble. The motor is complete with a modern safety lanyard and yes, more lime green paint.

This project demonstrates that the next generation of inventors, fabricators, and builders is ready, willing and able to learn new skills. The experience deserves to be celebrated and we hope more youth become interested in this or any similar endeavor.

In August 2019, Joshua displayed his finished hydroplane at the 42nd annual Les Cheneaux Antique and Wooden Boat Show in Hessel, Michigan located in Michigan’s beautiful Mackinac Straits region. He represented his accomplishment alongside several other youth projects and their families sponsored by ACBS. The conversations with attendees about their own childhood boating experiences alone were worth the effort. I am proud of Joshua—he is my son after all—but I am equally as proud to have confirmed that today’s youth are just as capable as ever.

Thank you for sharing in our journey and best of luck with your own inspired projects.