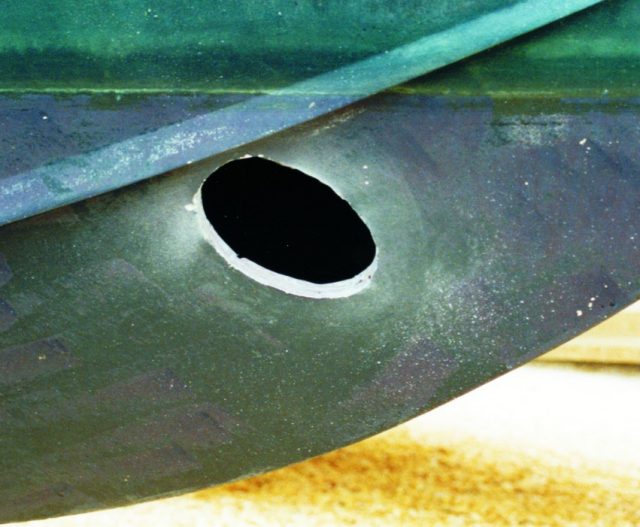

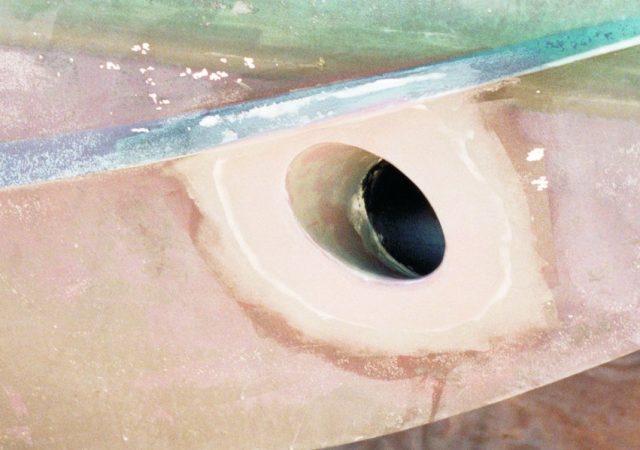

Above: After installing the bow thruster, the fairing compound is sealed with epoxy, and bottom paint is applied to the boat’s exterior.

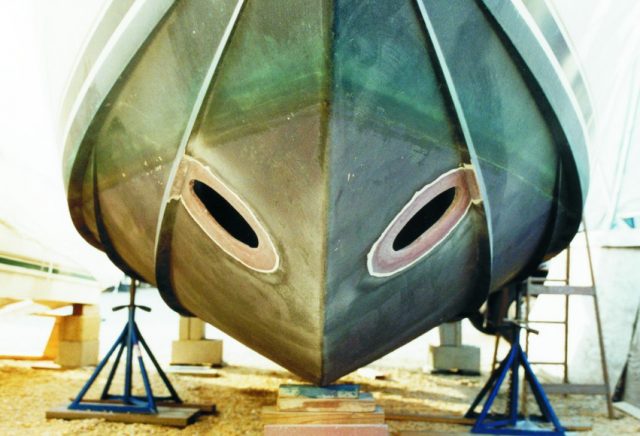

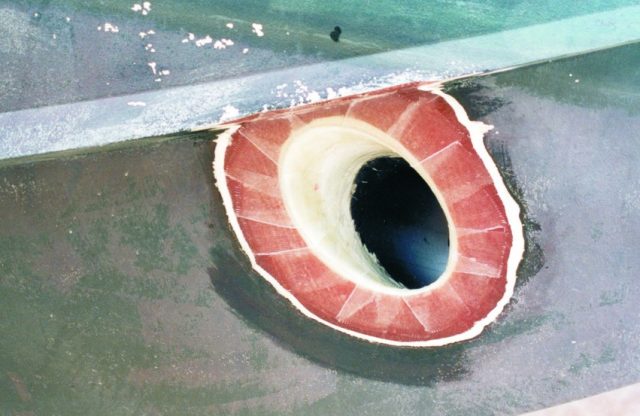

Island Heights, New Jersey architect, John B. Wilson, needed to install a bow thruster in his 26′ Albermarle sport fisherman, using WEST SYSTEM® Epoxy products. The toughest part of the job was cutting through the 1″ solid hull laminate. After trying several tools, he had success with a Roto Zip™ with a ½” carbide bit by making two ½” deep passes. The only other difficult job was cutting away a portion of the floor in the storage area under the V-berth to make room for the 5″ diameter thrust tube. The Vetus unit Wilson used delivers 77 lbf of thrust. In hindsight, Wilson says he should have used the next size larger unit. It delivers more thrust and uses the same size tube, but the larger motor would have been more difficult to fit under the V-berth.

Wilson’s photos documented the sequence of steps for installing his bow thruster.