Sailing Canoes

By Hugh Horton

The cover of Epoxyworks 16 shows Serendipity, the sailing canoe I built for Meade Gougeon on a Bell “Starfire” hull after he had seen me sailing my Starfire-based Puffin in the summer of 1998. The Starfire hull was designed by Dave Yost.

Sitting at the lunch table in the Gougeon’s boat shop in 2001, Meade said he was thinking of building a few Serendipity sisters and asked me if I’d like one too. I said no because

I wanted to build the plywood hull I’d been sketching. But after glancing around the table at Jan and the others, I changed my mind.

We bought six carbon and Kevlar Starfire bare hulls. I built a plug for the Serendipity sisters’ decks and we made a mold. All hands helped with vacuum bagging the decks. I molded the Kevlar™ coamings and built the seats. Meade organized and built the rigs. Meade, Jan, Rob Monroe, my wife Kayann and I sail and paddle the Serendipity sisters mostly in the Great Lakes and along the west coast of Florida. Howard Rice sails Sylph at home in Micronesia. One Serendipity sister remains unfinished.

Bufflehead’s development was helped immeasurably by refinements to the Serendipity sisters and Kayann has her Walela.

Bufflehead

Bufflehead (pictured at top) is 15′ 6″ by 33″ and the Serendipities are 15′ by 34″. Bufflehead’s displacement is 380 pounds while the Serendipity boats displace about 300. But these numbers do not show how much more full-ended Bufflehead is below the waterline, nor her great reserve buoyancy. Both qualities help fast sailing more than they hinder slow paddling and light air sailing. I’ve increased the sail area to 54 square feet from the sisters’ 41 square feet or Walela’s 44 square feet.

The Plans

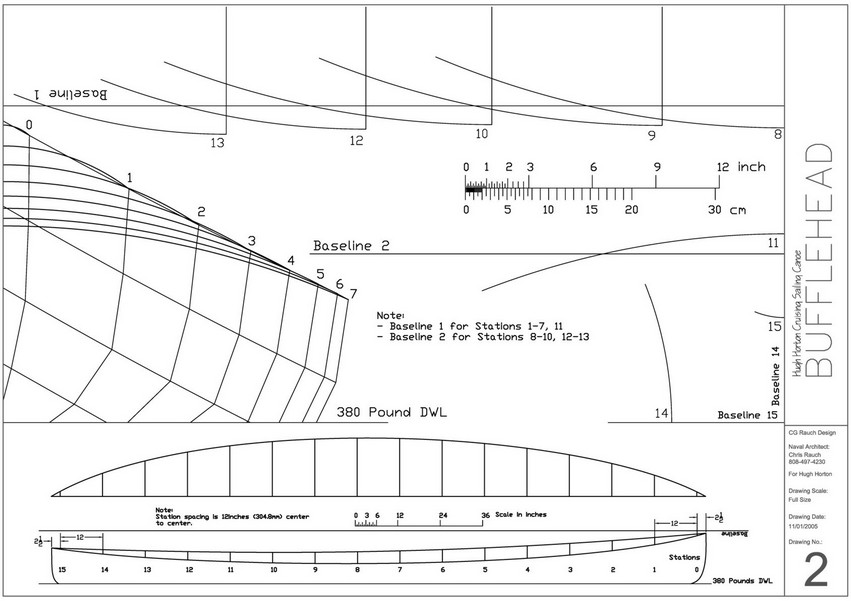

Bufflehead’s plan has no construction drawings. Rather than trying to offer a foolproof system for building, I caution that Buffleheads are for experienced builders and sailors who can choose their preferred construction method for building a lightweight boat.

Plywood and wood composite structures can be durable and light and are fully within the construction capacity of many garage boat builders. As a starting point in Bufflehead’s plans, photos show how I and others have built our Buffleheads. A bibliography of building techniques is in the plan, too. Experienced builders know, though, it’s still a sailboat and the hull and deck are just the beginning.

The Bufflehead plan has everything the experienced builder needs: full-sized stem profiles and body plan for either ply or strip construction, and patterns for the chined deck strakes. The deck sections for a strip built deck or for the jig for the chined deck come as a PDF. Critical dimensions are on hard copy sketches or JPG image files. Details are available from photos of the object being built, in use, or on a one-inch grid.

Small parts can be built on the kitchen table. I mold or glue components where the epoxy and I are most comfortable. Mast fittings, the rudder case, the leeboard tube and the seat parts can be built in your dining room. The sanding portion of any of this, much of which can be done by hand, I do outside in a breeze in good light.

Flotation

Flotation is important. You must have enough flotation, and it must be placed properly. Just not sinking isn’t good enough; you must be able to rescue yourself, to right your boat, and sail or paddle away.

I prefer a wide-open hull with no obstructions, in which I’ve secured plenty of effectively placed flotation. Flotation held by nylon mesh can be proprietary kayak or canoe bags, dry gear bags, plastic bottles, box wine bladders, closed-cell foam blocks, etc.

Nearly any flotation can keep your boat afloat in crisis. But it must be secured and placed widely enough to prevent the boat from rolling, not just high and not just low.

Others prefer full bulkheads and sealed chambers. Howard Rice wants his Bufflehead to be self-bailing, too, so he can proceed after capsize, using Elvstrom-style bailers to suck water out of the boat as he sails away.

Rigging on a Bufflehead Sailing Canoe

Will you be satisfied with a prototype rig? Is a piece of 6061 aluminum pipe okay for your mast instead of a carbon one? Or are you convinced you want to try a gunter and its advantages, in spite of reefing eccentricities waiting to be resolved? Or do you not care a whit about fine windward performance and prefer a traditional, low-tech rig?

I delivered Meade’s Serendipity with a light, free-standing, rotating gunter with a sprit boom, one reef, and no battens. As Meade wrote in Epoxyworks 16, “Hugh challenged me to come up with a better rig, which I attempted nearly immediately.”

Meade has evolved a series of fully battened sails, using full or half wishbones. Besides being the “patron saint” of cruising sailing canoes, Meade has led the way in rig development. His first mast was aluminum, the rest have been carbon spars. Each of us has experimented, too.

Gunters had been my favorite for their unique advantage of the mast reefing with the sail. The gunter has neither extra windage nor mass swinging about above the reefed sail. The spars can be built more as a woodworking project than a molding project. For better upper sail shape, Stu Hopkins of Dabbler Sails helped me with a “batwing” gunter. A long batten springs from the heel of the yard, so the yard and batten lower and fold down as easily and reliably as any rig, and one can have a full, shapely roach. My first batwing gunter had a half wishbone boom, derived from Meade’s design. The latest has a sprit boom.

The rig I recommend now is Meade’s style of rig, a fathead, full-length battened sail using external hoops and clips, set to shape by a sprit boom or full or half wishbone boom. It’s shown with Stu’s sail and Ron Sell’s mast on Jim Renouf’s Bufflehead Eden and in some photos on my Bufflehead.

The seat. Aye, mate, there’s the rub. The seat must work for two disparate activities, paddling and sailing. I scoot the seat side-to-side a foot, and twice that fore and aft. For sailing, I usually want to be low and slouchy, but high or low with kinetic and isometric action is much of it, too.

I delivered Meade’s Serendipity with a light, free-standing, rotating gunter with a sprit boom, one reef and no battens. As Meade wrote in Epoxyworks 16, “Hugh challenged me to come up with a better rig, which I attempted nearly immediately.”

When paddling actively I want the seat firmly in place, but not more fixed than needed. The friction of the seat’s bare teak corners with the scuffed Kevlar bottom is usually enough, along with my mass and feet holding or pushing. For either single-blade paddling or double, I want to sit inches higher than when sailing. For double-blade paddling, I usually want to be centered. The harder I’m paddling, the more I want to be sitting upright.

My seat design is effective but time-consuming to make. Some Bufflehead sailors use Legacy Paddlesports fishing kayak seats.

Paddles I use both double-blade and a single-blade paddles. I tend to think of the double for going and the single for sightseeing or for a stroke here or there. Often I carry five paddles: two double-blades and three singles, one of which is a specialized deck paddle. I love mine, a straight shaft beaver tail that Ron Sell built to my sketch. It’s only four feet overall because I sit low for sailing. The thin blade extends well up the shaft for low-seat Omering, a version of Northwoods or Canadian paddling in which the blade stays underwater on the return stroke. It’s silent and my hands are dry enough to change camera batteries. It stows smoothly on deck.

Our double-blades are longer than those used with white water kayaks or with narrow sea kayaks because our beam is wider with more freeboard, and we’re usually paddling at lower angles. The leeboard is an NACA foil section from, say, 0007 to 0012. It pivots up and down from a horizontal tube on the port side, perpendicular to the boat’s centerline. Its mount does not cross the cockpit. Its friction system by Jan Gougeon is by far the best I’ve seen. He has an evolution of it in mind using a tapered axle in a cone, rather than a cylindrical axle in a tube. Either way, friction is easily set as it’s wanted for fingertip control, and it stays put.

The rudder blade is an eight-inch 6061 aluminum plate. The case is ply and carbon. Dual steering control sticks are lashed to a wood composite yoke.

If Buffleheads were not agile and easily turned due to their rocker, I’d think about a foiled rudder. But the low drag flat plate is effective, durable, and foolproof.

At the 25th annual Cedar Key small boat meet in May 2009, I watched Meade beach his Yello Thing among three Buffleheads. At the time, Yello Thing was borrowing his Serendipity’s sail and rudder. Those four boats were derived from Puffin through Meade’s Serendipity and were much better because of the lunch table conversation nine years before. Now Meade is adapting Serendipity’s seat back to support his head and shoulders for dozing. It’s an idea I’ve wanted to develop too, and another one on which he’s a step ahead.