by Captain James R. Watson

If you’ve had quantities of left over WEST SYSTEM® Epoxy after completing a project, you may have wondered how long the material would remain usable. Epoxy users have asked us these kinds of question regarding older epoxy:

“I bought some of your epoxy at a rummage sale, it’s old, is it still okay to use?”

“I know my epoxy sat in a shipping truck in freezing conditions, is it going to be all right to use?”

“My hardener appears to have changed color and has a different odor. What affect might it have on my project?”

These concerns have to do with shelf life. This, and related issues are discussed in this article.

When something we expect to be the same appears different, we get worried. But most of these concerns hinge on changes that may not jeopardize the material’s quality either for application or when cured. Let’s investigate.

Shelf life

Shelf life is the time a material may sit unused and still perform as designed. Shelf life commences when a material is made. The shelf life of some materials is shortened once the package is opened, others not. For example, a can of soda can sit on a grocers shelf for a year and still tastes fine when opened. But no matter how long it sat unopened, it is best when first opened and afterwards quickly looses fizz and flavor. Honey, on the other hand, seems to retain its consistency and flavor indefinitely, even after the jar has been opened.

We have mixed 15-year-old WEST SYSTEM 105 Epoxy resin with newer hardener and it cured fine (See Shelf Life in Real Life). Although material that is several years old should cure as designed, you might want to save it for applications where strength or clarity are not paramount.

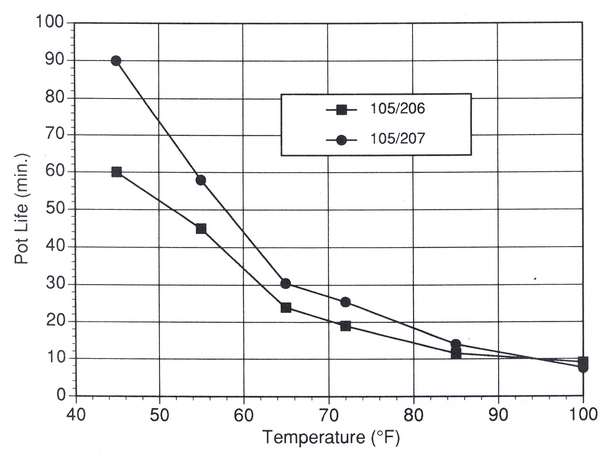

The easiest, most accurate method to test questionable resin and hardener is to perform a simple pot life test. In an environment of 72°F, combine a total of 100 grams of resin and hardener (at proper ratio) in a 2″ diameter container. Begin timing and stir for exactly 2 minutes, then set it aside. Don’t hold it, because your body heat will accelerate the cure and skew the results. Take caution, as larger amounts of epoxy can produce high heat during cure. Note when the epoxy gels; this is the end of the mixture’s pot life. If the resin and hardener are still good, you should have obtained the following results:

Temperature has a dramatic effect on pot life. A temperature increase of 10°C (18°F), will cut the pot life approximately in half. A small change in the temperature where you are running the pot life test will effect the results. Figure 1 in the gallery below shows the relationship between temperature and the pot life of WEST SYSTEM 105/206 and 105/207 at 72°F.

WEST SYSTEM resins and hardeners do no have a strict shelf life. Certain changes may make them less effective for some jobs, but the resin and hardener will still be reactive. Will you will note a expiration date on the product containers, this is because we are an ISO 9001 company and keep “retains” of every batch we make. Due to the many batches we make and space limitations, we only keep these retains for 2 years. The “expiration dates” on our containers are 2 years from the date of manufacturer, but actual shelf life is typically far longer.

Changes in product characteristics

WEST SYSTEM 105 Resin

The viscosity of 105 Resin is very responsive to temperature (see Figure 2 in gallery below). A seemingly slight decrease in ambient temperature can effect viscosity noticeably. This makes pumping, pouring and stirring much more difficult. Simply warming the resin solves this problem.

Unrelated to temperature, resin may thicken after several years. This condition is not reversible, but the product can still be used if extra care is taken to ensure thorough mixing with hardener.

Decades ago, the resin was susceptible to crystallization which made it appear milky. This was aggravated by exposure to freeze/thaw cycles. But crystallization was easy to revert by heating the resin, much the same way crystallized honey is restored. Today milky, crystallized epoxy is rare, thanks to a slight reformulation of the product. But if it crystallizes, warming the can in water bath and gently stirring should resolve this.

WEST SYSTEM 205 Fast Hardener

This hardener may emit a strong ammonia-like odor if it has been stored in a closed container for a long time. Once opened, the ammonia odor escapes and the hardener’s scent returns to normal.

Exposure to metal may cause the 205 Fast Hardener to turn deep red or purple. The metal from certain large capacity dispensing pumps may accelerate this condition, and exposure to the metal of the hardener container may also cause this change. The hardener’s color will not affect the epoxy’s cured physical properties. In thin film coatings, the color is difficult to detect, but mixed with white fillers it becomes very noticeable. The hardener color change is not reversible.

WEST SYSTEM 206 Slow Hardener

This product can also emit a strong ammonia-like odor, but is not as likely to turn red.

WEST SYSTEM 207 Special Clear Hardener

This product is not prone to reddening. Thin layers of 207 Hardener, (such as a drip from a mini pump) may solidify from exposure to air. This can plug the pump nozzle and have to be ‘picked’ away.

WEST SYSTEM 209 Extra Slow Hardener

A thin film of this hardener may also solidify when exposed to the air. This white solid is the result of a chemical reaction between a component of the amine hardener, moisture and carbon dioxide (CO2) in the air. A strong ammonia-like odor may develop if it is stored in a sealed container for a long time.

When age is not the issue

Most often, problems with older epoxy are not related to age but to some other condition, such as the presence of a contaminate.

Moisture contamination is a common culprit, especially when the product is left outside with the container top off and dew or rain finds its way into the container. Condensation inside a container can occur when stored in a cold environment and warmed quickly.

Hardener/resin cross contamination

Sometimes through carelessness, hardener finds its way into the resin container or vice versa. This form of contamination is marked by chunks of cured material or stringy areas. This can happen if one spoon is used to draw both resin and hardener. Not much can be done to resolve this form of contamination, and both resin and hardener may be wasted.

Other contaminates may factor in. An epoxy container stored on a damp surface such as a basement floor can corrode, contaminated the contents of the can. Other common contaminates include dirt, saw dust, sand or dust particles, all of which can easily enter an uncovered container. Contact with chemicals, oil, paint or solvents can also permanently damage resin or hardener.

Excellent Shelf Life Helps Offset the Cost

Those who have used polyester resins know that its shelf life is only about six months. Afterwards, it turns to a useless jelly-like substance. An abundance of expired material can easily offset any initial cost savings these materials may offer. Fortunately, WEST SYSTEM Epoxies are not so limited. Their excellent shelf life, augmented by proper storage and good housekeeping, permit quantity purchases. You can always have some epoxy handy for whatever little project may come along.