By Tom Pawlak — GBI Technical Advisor

This fast blister repair method is tailored to fixing individual gel coat blisters prior to bottom painting. The advantage of this method is it can repair blisters on hulls recently pulled from the water or hulls that have been out for some time.

Fast Blister Repair Method

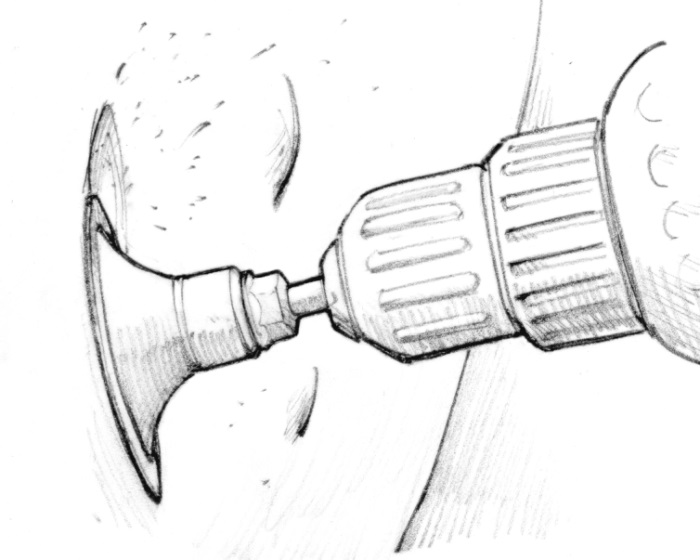

- Open the Blisters

Open blisters with a small abrasive tool like 3M’s Rolock™. 2″ diameter sanding disk with 60-grit sandpaper. Make sure you have removed the entire blister, including the edges of the blister dome.

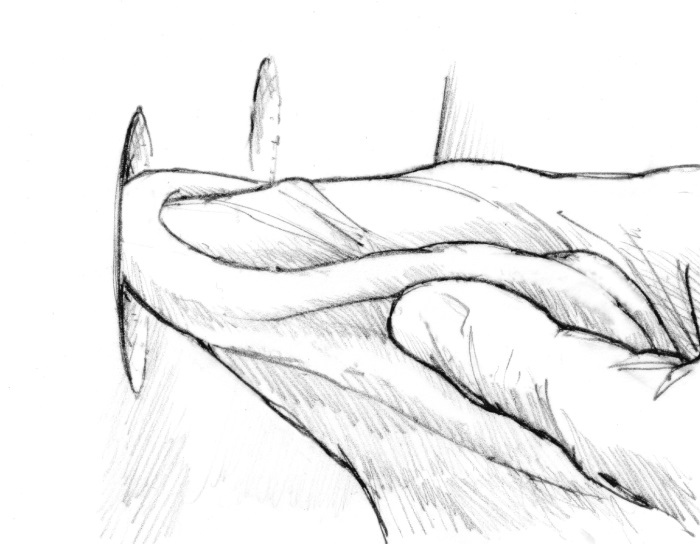

- Clean the Cavity

Wipe the cavity clean with an alcohol prep pad or paper towels that have been soaked in isopropyl alcohol. Be generous with the alcohol and change towels frequently so the contaminants are removed rather than spread. Repeat the alcohol wipe process and allow the laminate to dry to the touch. It is particularly important to repeat the alcohol wipe on blisters that were fluid-filled at the time they were ground away.

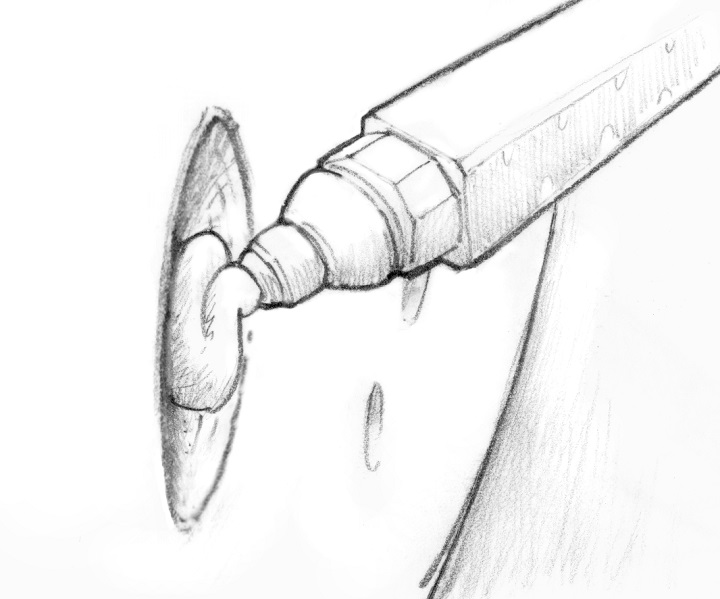

- Fill with Six10

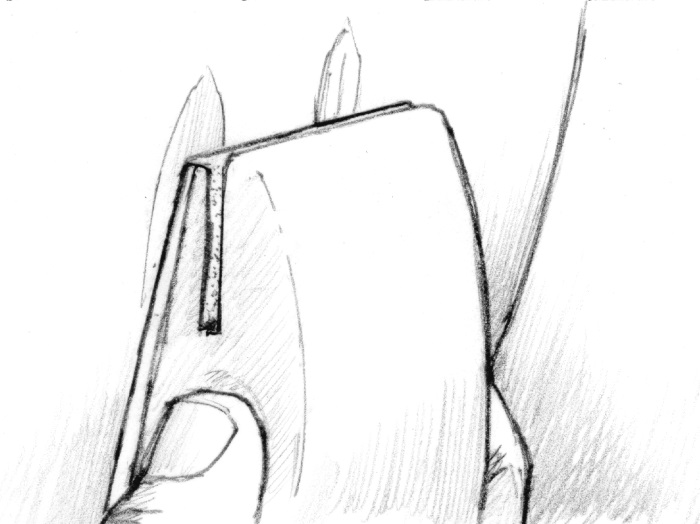

Fill the cavities with Six10 Thickened Epoxy Adhesive dispensed through the static mixing wand.

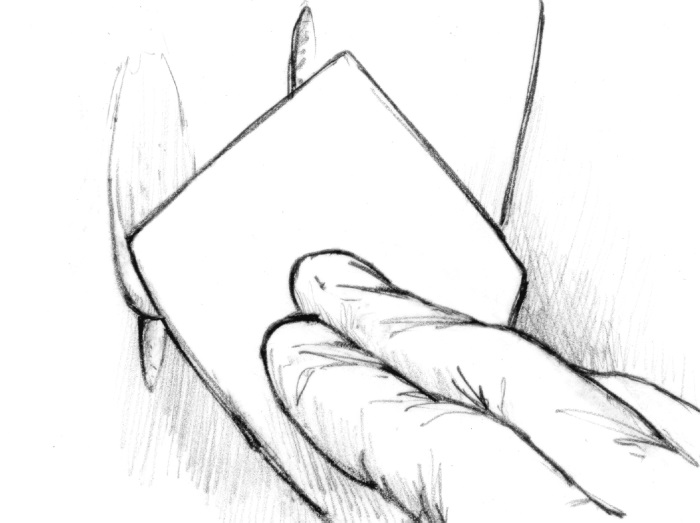

- Spread the Six10

Spread the Six10 Adhesive flush with the surrounding hull with a wide putty knife or plastic spreader. Avoid overfilling the cavities because Six10 is difficult to sand.

- Wet Sand

Wet sand with 80–120-grit wet/dry sandpaper or wash with water (no soap, no ammonia) and sand dull with 100-grit sandpaper. If you are using Six10 in warm conditions, you should be able to wet sand and bottom paint later the same day. If working in cooler temperatures, allow the epoxy to cure overnight before sanding.

- Paint

The final step is applying your choice of bottom paint to complete this fast blister repair job.

Why this Fast Blister Repair Method Works

Six10 Adhesive is epoxy thickened with fumed silica, which allows the epoxy to remain an excellent moisture barrier. When the static mixer is used to dispense it the blister cavity is filled with air-free epoxy. This is important because small bubbles in coatings and putties degrade moisture barrier potential by creating shortcuts for moisture to permeate the hull. In the end, Six10 produces a moisture barrier that is better than the original gelcoat.

In our Gelcoat Blister manual, we recommend filling and fairing extensively blistered hulls with WEST SYSTEM® Epoxy thickened with one of our low-density fillers (407 Low Density or 410 Microlight®). The hollow microscopic spheres used to make low-density fillers easy to sand, make them poor moisture barriers. So, the blister manual requires that an effective epoxy barrier coat be applied over the filled and faired surface.

Six10 Adhesive is an excellent option for filling ground-out blister cavities—especially if you don’t plan to barrier coat your hull.

More Good Reasons for Using Six10

Six10 is simple to use. No stirring is required when the epoxy is dispensed through the static mixer. The Six10 cartridge fits any standard caulking gun and always dispenses epoxy at the perfect mix ratio. Six10 makes filling blisters easy and efficient. This is comforting to know whether you’re doing the job yourself or paying someone else to do it.