by Captain James R. Watson

Dragging your catamaran over sandy beaches can abrade away material on the bottom of the hull, thereby flattening the sectional shape. Usually this area will extend 4 or 5 feet each way of the hull’s mid-section. You need to fix it so it doesn’t wear through, and to maintain optimum design performance.

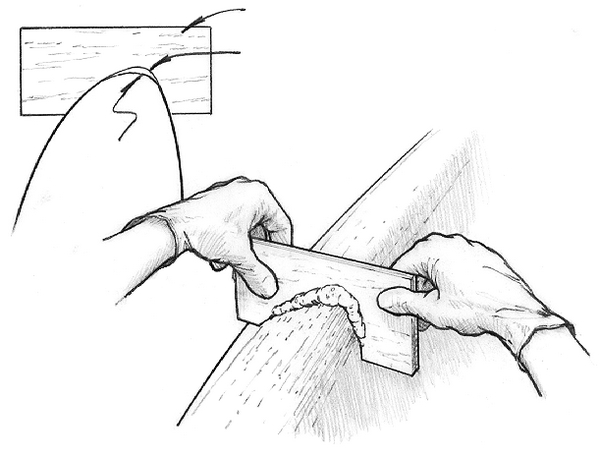

To repair, flip the catamaran over. Use dividers to scribe the hull shape onto ¼” thick plywood, or a similarly rigid material that can be cut and shaped to yield a template describing the existing bottom profile. Then, using drafting curves or freehand, draw in the estimated original or desired profile and cut the template. Several templates may be required if the flattened section extends to areas where the template does not fit the hull. The template should fit both hulls by simply flipping it over.

Sand the repair area with 50-grit sandpaper to prepare the surface for bonding. Mix WEST SYSTEM® 105 Resin and 205 Fast Hardener, then stir in 406 Colloidal Silica to produce a peanut-butter-like consistency. Spread this mixture over the repair area. If color is an issue, you can use a small amount of pigment to the mixture. Use the templates to shape the thickened epoxy and scrape away the excess to achieve the original hull shape. Smooth in the transition areas with a plastic spreader. When the epoxy has cured, sand it with 50-grit sandpaper and a long sanding block.