by Bill Bertelsen—GBI Test Engineer

Our Technical Advisor Jim Derck (now retired), noticed that some fabrics seemed to have a remarkable thirst for epoxy. To determine exactly how much epoxy it takes to wet out and bond different kinds of fabric, Jim conducted a carefully controlled experiment.

First he weighed and measured large pieces of several kinds of fabric and calculated their specific weight in ounces per square yard. He then cut 14″ x 14″ squares and squeegeed epoxy into one or two fabric layers over waxed glass.

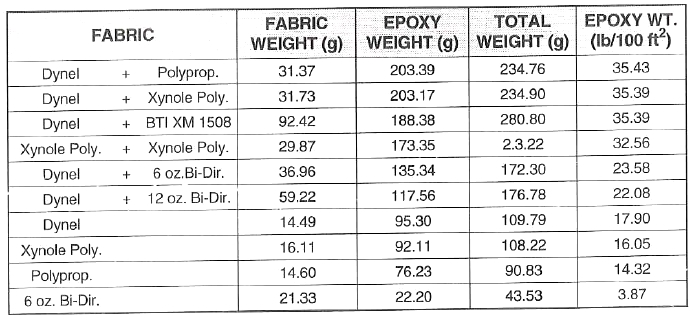

When these samples cured he removed them from the waxed glass and trimmed them to 13″x13″. He then weighed them a second time determine their epoxy content. The table above shows the results. The fabrics are ranked highest to lowest in epoxy take-up, as reflected in the listing of pounds of epoxy needed to treat a 10’ x10’ area (lb/100 ft²).

Jim applied enough epoxy to ensure a complete wet-out. This was not necessarily enough epoxy to completely fill the weave. Up to 30% more epoxy could be required to fill the fabric weave.