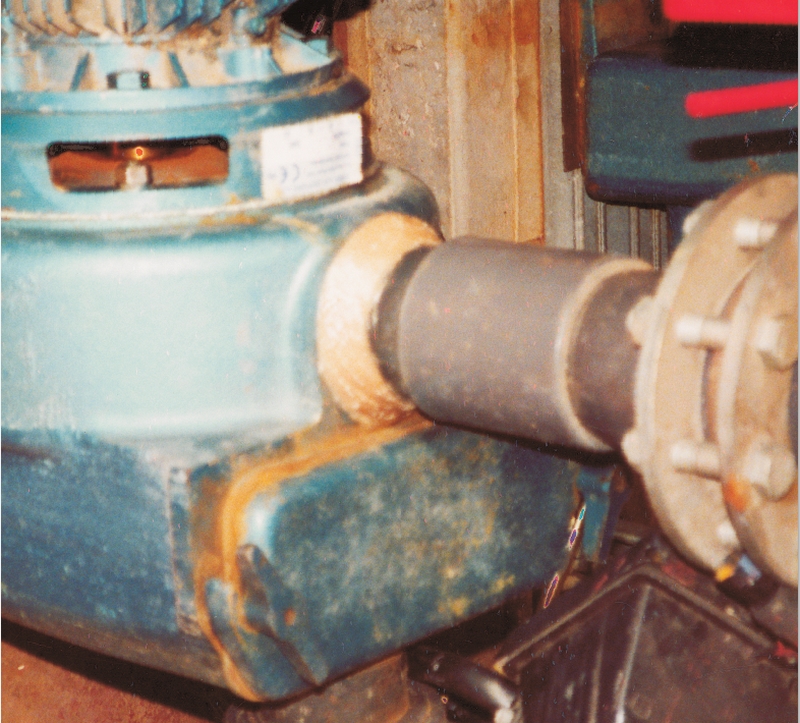

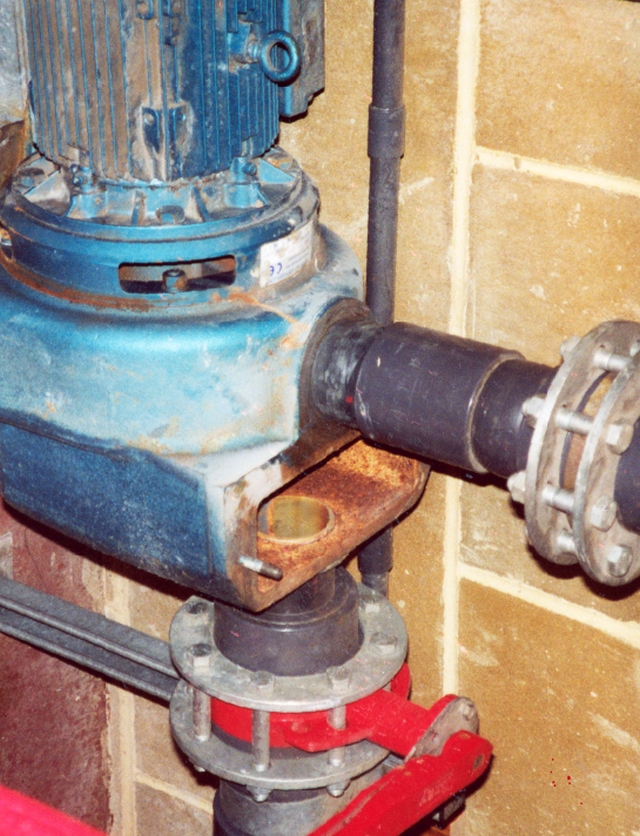

Above: The pool pump repair was 100% effective four months later.

Barry Bew, a sailing instructor at Arethusa Venture Centre, Gravesend, Kent, UK, used his experience as a plant engineer to make an emergency repair to a swimming pool circulating pump. The pump was leaking at joints between the 3″ ABS plastic inlet and discharge pipes and the cast iron pump body.

Barry cleaned up both bonding surfaces by grinding down to clean metal on the cast iron, down to clean plastic on the ABS pipes contaminated by thread sealant. He flame-treated the ABS bonding surface. He also applied a coat of unthickened epoxy to the cast iron bonding surfaces, then [wet] sanded the fresh epoxy into the surface.

Barry first applied a small fillet, with a minimum amount of filler added, around the joints. After the small fillet gelled, he applied a larger, thicker fillet around the joints. He allowed the epoxy to cure for 72 hours, keeping the cast iron warm with a fan heater, before pressurizing the joints. The pump’s output pressure is 15 psi. Barry reports the repair was still 100% effective four months later.