By The Teak Connection

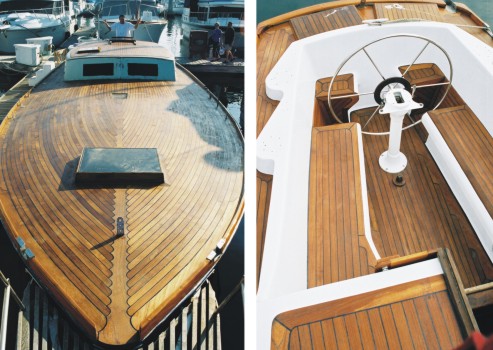

When it comes to meeting the challenges of the marine environment, no wood so nicely fits the bill as teak. Teak is a strong, hard, rot-resistant material. A naturally oily wood, teak will withstand the assault of the marine environment better than any other wood species. Teak is well suited for a variety of interior and exterior applications—from elegant teak and holly cabin soles to rugged toerails and handrails. Oiled, varnished or left natural, teak presents a rich, subtle beauty that is synonymous with traditional watercraft and quality. The color of fresh-cut teak ranges from light green to tan to brown. If left exposed to the elements without protection of oil or coating, it will weather to an attractive light gray color.

While there are a variety of teak sub-species and look-alikes, Burmese teak, Tectona Grandis is the finest timber available. This grade of lumber consistently offers the long-term performance and stability required in the marine environment.

Protective treatments

There are four popular methods of treating teak surfaces. Each has advantages and disadvantages, and each should be carefully weighed before committing to one method.

Natural—Teak is one of the few woods which can be left natural without deteriorating. An occasional water wash down will keep grit and dirt from being ground into the wood grain. There are also commercially available teak cleaning solutions which will help restore weathered, gray teak.

Oiled—Many owners prefer the look of oiled teak. Oiled teak will retain its golden color longer than natural wood, and the oil will help to keep the wood from drying out. It is a temporary treatment at best, and requires periodic re-oiling. This may range from once a season in the Great Lakes to as many as four times a year in South Florida. In subtropical climates, oiled teak is also subject to mildew growth which darkens the wood over time. Mildewed teak can be restored to near its original color by using commercially available treatment systems.

Varnished—There is nothing quite so beautiful as a deep coat of varnish on your teak. Clear varnish will showcase the beauty and warmth of the wood grain while protecting the surface. Many varnishes today also provide ultra-violet light protection for the wood. Of course, varnishing is a time-consuming project. Varnished exterior wood usually must be sanded and recoated annually, while interior surfaces may last for years before they need refurbishing. Care must also be taken to touch up nicks and dings in the varnished surface to prevent dark spots.

Epoxy coated and varnished—This last method is best used in new construction. It involves coating all wood surfaces with a mixture of WEST SYSTEM 105 Resin and 207 Special Clear Hardener, then applying multiple coats of varnish over the epoxy. The epoxy virtually eliminates the movement of moisture into and out of the wood. This makes it more resistant to cyclic swelling and shrinking, and provides the ultimate stable base for varnish. In addition, the hard epoxy coating protects the wood grain from nicks and dings. Varnish with a strong UV resistant additive is still required, however, because sunlight damages epoxy. The key to this process is coating all of the surfaces of each piece of wood with epoxy, which makes it particularly applicable to new construction.

Storage

Your investment in wood stock is just that, an investment. Take care to protect your teak lumber and plywood while storing it. Stack the wood off the ground, using evenly spaced wooden slats every foot or so. Prevent sagging and warping by using a lot of spacers to provide support beneath the wood. Also place spacers between individual wood pieces or sheets. Good air circulation will promote the continued seasoning of your material and help prevent mildew and rot. Lastly, keep the teak covered against rain and snow.

Working with teak

The same properties that make teak such a desirable building material also make it difficult to work with. Teak is tough on tools, and requires sharp blades for clean, fair cuts.

Teak is a naturally oily wood. When gluing it you must take extra care to ensure solid bonds. Your best choice for bonding teak is G/flex 650 or G/flex 655 epoxy. Abrade the teak’s surface with 60-grit sandpaper, then thoroughly wipe the surfaces with paper towels and alcohol or solvent immediately before bonding. As soon as the wood is dry, liberally coat all bonding surfaces with epoxy, assemble and then clamp or fasten. Don’t exert too much clamping pressure, which will squeeze epoxy out and result in a glue starved joint. If the bond will call for filler, 405 Filleting Blend is the best choice.