By Rachael Geerts – GBI Composites Materials Engineer

Here is an inside snapshot of how the composites materials world is growing at my alma mater, Winona State University. Located in Winona, Minnesota, this university has the only accredited four-year undergraduate program for composite materials engineering in the US. Through this program, students learn the fundamentals of engineering while investigating different materials. This program challenges students both academically and creatively. Students are encouraged to ask questions and strive for a deeper understanding of why things are done the way they are done. From this, they can explore how things can be improved.

Starting freshman year, students learn about what a composite material is and where composites can be found in the world around us. They go on to learn about the properties of materials and recognize when to use different types of reinforcements. Students engage early on with the composites industry as they tour local composite businesses in Winona, listen to experienced speakers, and get engineering internships.

Composite Materials Engineering Program Internships and Opportunities

Students intern in many different areas of the composites industry. They do anything from working year-round at a local material supply plant conducting different types of material testing to a summer internship in another state, working on renewable energy technology. Winona offers a wide expanse of opportunities for students to apply what they’ve learned in classes, increase their knowledge, and figure out which part of the industry they’re passionate about and would like to work in after graduation.

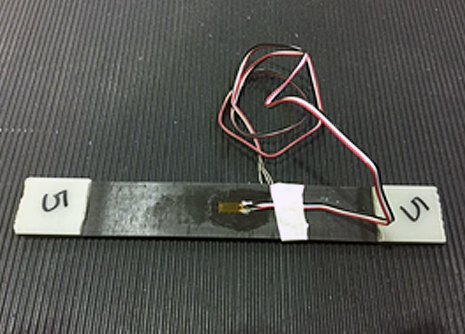

During junior and senior year, students get more opportunities to work with composites in a shop setting. In addition to typical engineering topics such as Statistics, Thermodynamics, and Fluid Mechanics, course topics unique to the program include Mechanics of Composites, Polymer Science and Characterization, and Engineering Seminar. They make reinforced panels and test them at the beginning of their junior year. The academic and hands-on experience culminates with the senior design project. Students engineer and produce a product that they believe there could be a market for. They explore the different aspects of manufacturing from material selection, to researching the potential market, to assessing production costs.

Support, Material Discounts and Scholarship Program from Gougeon

Gougeon Brothers Inc. has supported Winona State University’s preparation of students for jobs in the growing composites industry through material discounts and by employing graduates of Winona State. Students become familiar with epoxies in the lab thanks to Gougeon’s support. The company also started a scholarship program for students at Winona State in the engineering program in memory of Mike Barnard. He was both a Winona graduate and a Gougeon employee. This scholarship helps students to pursue their goal of making an impact on the composites industry, as Mike did here. As a current employee of Gougeon Brothers and as a Winona State alumnus, I am grateful for Winona State’s preparation and Gougeon’s support of education in the composites field of study.