By Joe Parker

Customers frequently ask us about calculating epoxy or the amount of fiberglass fabric necessary to build or repair a fiberglass laminate. My son Brad and I are about to build a fiberglass canoe, so I will use that as an example to describe how to determine material needs for a project.

While explaining to Brad how to calculate our glass and epoxy material requirements, I realized I was describing a technique he had recently learned about in school. It’s known as approximation and described in The New Lexicon Webster’s Dictionary as “a method of solving problems by a progressive approach to an exact solution.” He had explained the concept to me about a week earlier, and I realized I have used the approach most of my life without knowing that it had a name. I am going to describe all of the steps necessary to arrive at a weight and volume prediction, but in many cases, you can skip some of the steps.

Calculating the area

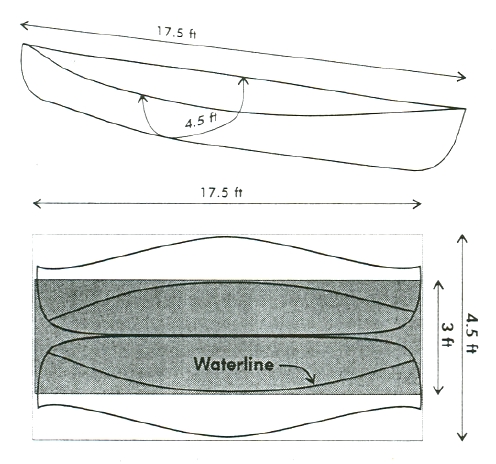

The canoe is 17.5 feet long, and has a maximum girth of 56 inches (measured around the bottom from gunwale to gunwale). Now let’s approximate the rectangular shape of the canoe if it were laid out flat. The length is 17.5 feet and the width is 4.5 feet (rounded to the nearest ½ foot) for a total surface area of 79 square feet. [17.5 × 4.5 = 79 sq. ft.]

I think I want to use two layers of WEST SYSTEM 738 Episize Biaxial Fabric over the whole thing, and an additional layer on the area below the waterline on the outside of the core. So next we need to figure out the area below the waterline. Again, 17.5 feet multiplied by the width at the waterline (34 inches, rounded to 3 feet) is 52.5 square feet. [17.5 × 3 = 52.5 sq. ft.] Next, we calculate the total area of all of the layers combined. Two overall layers of 79 square feet plus one partial layer of 52.5 square feet is 210.5 square feet. [(79 sq. ft. × 2) + 52.5 sq. ft. = 210.5 sq. ft.]

Calculating linear yardage of fiberglass

Now that we have the total area, we can calculate the number of linear yards and weight of the glass fabric. To calculate the linear yards, divide the total square feet by 12.5, which is the number of square feet in a linear yard of 50-inch wide fabric. [210.5 sq. ft. ÷ 12.5 = 16.8 yd.] Now we know that a 20 linear yard roll of glass will be sufficient to build the canoe, but we do not know how much it will weigh, or how much epoxy to buy, so let’s figure that out.

Calculating fabric and resin weight

The 738 Episize Biaxial Fabric is two layers of unidirectional glass stitched together at +45° and -45° to the roll length. The stitched material weighs 15 ounces per square yard. This material also has a layer of chopped strand mat added, which weighs about 6.75 ounces per square yard. The total weight of the material rounded to the nearest ½ ounce is 22 ounces per square yard. To determine the area in square yards, we divide the total square foot area by 9, the number of square feet in a square yard. [210.5 sq. ft. ÷ 9 = 23.4 sq. yd.] Now that we have the area in square yards and the weight of the fabric per square yard, we can determine the total weight of the glass. Area times weight per unit of area equals the total weight in ounces. Then we divide the weight in ounces by 16 to get pounds. [(23.4 sq. yd. × 22) ÷ 16 =32.2 lb.]

I know that if I take my time and wet the fabric properly, the laminate will have a resin to fiber ratio of about 50% by weight. After figuring out how many pounds of glass I have, I can use an equal amount of epoxy to wet it out. I usually add 15% to my estimate as a waste factor. You may find you have more or less waste, but this is a good place to start. So, 32.2 pounds of glass times 1.15 for a total of 37.02 pounds, rounded to 37 pounds [32.2 lb. × 1.15 =37.02 lb.]

I also know that the laminate will weigh the total of the glass fabric plus the epoxy to wet it out. [32.2 + 37 = 69.2] Wow, the canoe is going to be heavier than I had hoped. Now I need to decide if I really need that much glass in the laminate, and if I want to vacuum bag the part to reduce the weight. Remember, we used a rectangle to figure our areas, so the narrower ends will take some weight out.

Recalculating for a lighter craft

I figure the laminate schedule I started with would be a real rock basher, so I can probably take some of the glass out of the canoe and it will still be fine for general use. I am going to switch to 737 Episize Biaxial Fabric (15 oz. biaxial fiberglass without mat) for the inside skin, and for the additional layer of glass below the waterline on the outside of the core.

For the new outer skin, we will need 79 square feet of 738 Biaxial Fabric with mat, plus 52.5 square feet of 737 Biaxial Fabric for the additional layer in the bottom, plus an additional 79 square feet of 737 for the inside skin. Here is the formula to calculate all of the glass for the new laminate schedule. I am putting together the segments we used earlier for quick calculation.

79 sq. ft. ÷ 9 = 8.77 sq. yd.

8.77 sq. yd. × 22 oz = 192.04 oz.

192.04 oz. ÷ 16 = 12.59 lb. of 738 Episize Biaxial Fabric.

(79 sq. ft. + 52.5 sq. ft.) ÷ 9 = 14.61 sq. yd.

14.61 sq. yd. × 15 oz. = 219.15 oz.

219.15 oz. ÷ 16 = 13.7 lb. of 737 Episize Biaxial Fabric.

12.59 lb. + 13.7 lb. = 26.29 lb. total glass weight.

The total glass now weighs 26.29 pounds. Using our resin multiplier we see that we need 30.23 pounds of epoxy to wet out the glass. [26.29 × 1.15 = 30.23 lb.] The new total for resin and glass is 56.6 pounds. That’s a little better, but still kind of heavy. Let’s see if we can get the weight down a little more by vacuum bagging the laminate to reduce the resin content in the finished laminate.

Predicting vacuum bagged laminate weight

The amount of epoxy necessary to wet out the glass remains the same, but we will squeeze some of it out when we vacuum bag the laminate. Based on prior experience, I know that a good vacuum bagged laminate can yield a resin content of about 38% by weight in the finished part. The weight of the glass will remain constant, so we can figure out how much resin we will squeeze out, and predict the weight of the finished laminate.

First we have to arrive at a multiplier for the glass weight to get the resin weight. Divide the target resin content (38%) by the target glass content (62%) to get the multiplier. Multiply that number by the weight of the glass to determine the weight of the resin in the finished part. [38 (% resin content) ÷ 62 (% fiber content) = 0.6129; 0.6219 × 26.29 = 16.11 lb.]

Now we add the resin and the glass together to predict the weight of the finished laminate. [26.29 + 16.11 = 42.4 lb.] Now I can get Brad to carry this thing down to the river. That is the kind of canoe I want.

Now that we know the weight of the epoxy, it is very easy to determine the volume of resin and hardener. Divide the number of pounds of epoxy by the weight of a B group (gallon kit) of 105 Resin and 209 Hardener, which is 12.19 pounds. [30.23 lb ÷ 12.19 = 2.48.] To build the canoe, we need 2½ B groups of epoxy plus a little for the core.

If you were so inclined, it would be simple to put these formulas into a computer spreadsheet. Then you could change the fabric weight, the number of layers or the area for your laminate and get pretty good predictions very quickly.