by Ben Gougeon

An autopilot steering failure on his sailing scow Yello Thing forced Meade to withdraw from the 2010 Everglades Challenge. When he reached the shore, he was already thinking about building another boat for the next race.

The next boat needed to be more substantial to handle rough seas. It needed to be trailerable and comfortable yet still meet the race’s natural requirements. Meade and Jan began looking into the i550, an 18′ sportboat designed by Chris Beckwith. The pair decided that with a few modifications the i550 would be perfect for the race. They ordered the plans and construction began.

The i550 Sportboat Solution

The Gougeon Brothers technical staff constructed the hull in their shop with Captain James R. Watson overseeing the building process. The i550 sportboat is built with plywood stitch and glue construction. We used ¼” 5-ply Okume plywood and judiciously placed 5 oz carbon fiber. The entire boat was built with WEST SYSTEM® 105 Epoxy Resin® and 207 Special Clear Hardener®.

With all of the bulkheads in place the ties were cinched tight before fillets and fiber-glass tape were applied to reinforce the joints.The next boat needed to be more substantial to handle rough seas. It needed to be trailerable and comfortable yet still meet the race’s natural requirements. Meade and Jan began looking into the i550, an 18′ sportboat designed by Chris Beckwith. The pair decided that with a few modifications the i550 would be perfect for the race. They ordered the plans and construction began.

The first task was to scarf three 4′ × 8′ pieces of the marine plywood together using the WEST SYSTEM 875 Scarffer™. We constructed a simple jig to enable the proper cut point on the plywood to minimize waste. After cutting the panels, we bonded them together with a mixture of 105 Resin and 207 Hardener thickened with 406 Colloidal Silica filler. Then we lightly sanded the panels with a random orbital sander to clean the scarf joints and prepare the surface for a coating of 105/207 mix. We “flow coated” the surface by applying mixed epoxy with a 10″ drywall knife. This was an efficient, yet effective method to coat three 22′ × 4′ panels with epoxy prior to construction.

With the panels coated, we overlaid the Tyvek™ patterns (provided by Watershed Sailboats) on the panels and made reference marks to transfer the pattern shape for accurate cutting. Using a handheld jigsaw, we cut the patterns from the panel, careful to leave the original reference marks intact. It’s always easier to remove extra material later than it is to put it back on.

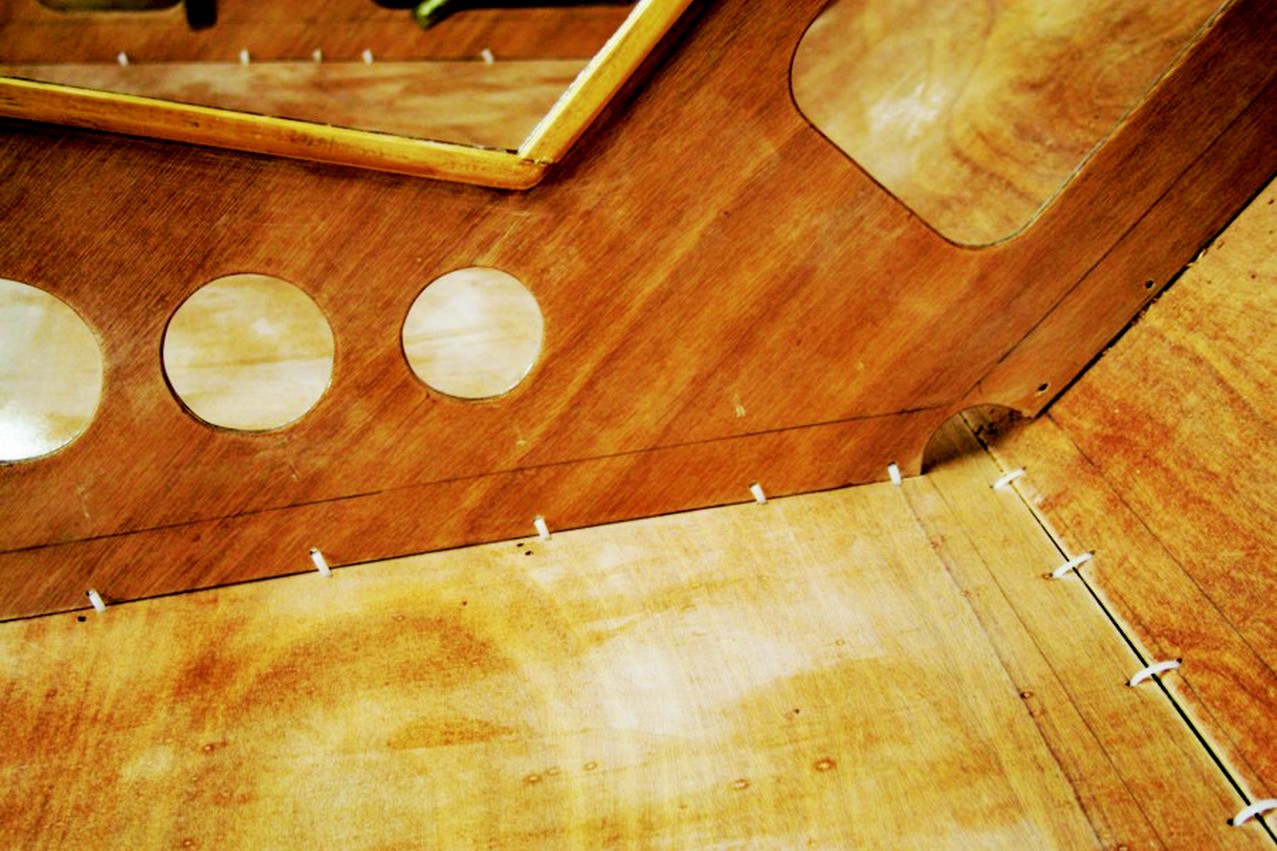

Captain JR Watson built an ingenious jig we used to set a scribe mark around the perimeters of the cut and trimmed panels. From this point, we drilled holes at 8″ intervals to allow for the HDPE zip ties to “stitch” the panels together.

We loose-fit the panels with the zip ties in place to achieve something close to the desired hull shape. With bulkheads fitted in the same manner, the i550 was starting to look like a boat.

After cinching the zip-ties we added some spacer modifications to the bulkheads to alter the hull camber midship and forward of midship. We tabbed the seams with WEST SYSTEM 732 Episize 9 oz fiberglass tape. When the epoxy had thoroughly cured, we removed the zip ties.

We then completed the cockpit, deck, stem, and stern using techniques detailed in the book, The Gougeon Brothers on Boat Construction. After completing the hull, we moved the boat across the street to the Gougeon Brothers boat shop for Meade and Jan to finish. They made a few modifications and customized the boat to fit the needs of the race. The i550 sportboat is a one-design class that allows modifications.

The Keel

The first thing we looked at was the bulb keel called for in the plans. Because we needed a shallow draft, we built a straight keel that fully retracts into the hull. This flush keel arrangement is ideal for moving the boat over land. The Everglades Challenge requires all boats to be manually moved from the beach to the water.

We cast a NACA 12% lead foil and attached it to a board with the same section. An aluminum crane fitted with a winch lifts the keel through the daggerboard case. This arrangement provides a sufficient mechanical advantage for one person to raise the keel to the desired height. The boat can be sailed with the keel up, down, or at any position in between. When portaging, the keel would be raised until flush with the bottom. The keel allows for sailing in shallow waters and for it to be easily trailered. With the keel cranked all the way down, the i550 is very seaworthy and has tremendous righting-moment.

Meade and Jan will use three heavy-duty, reinforced 10″ × 48″ beach rollers to move the craft over land. The rollers, stowed beneath the cockpit, serve double duty as positive flotation.

The Rig

The next thing we focused on was the rig. We bought a 25′ 6″ carbon fiber mast from C-Tech in New Zealand. Because the rig has to be lowered during the portage and pass beneath a 10′ high train bridge, we fitted the craft with a tabernacle instead of a standard mast step. This tabernacle allows one to raise and lower the mast without assistance. No gin pole or stay guides are required. All internal halyards pass into the tabernacle and route to the cockpit.

The Rudder Assembly

Because the rudder was the major source of malfunction on Yello Thing, Meade knew the i550 sporboat needed a forgiving steering system. He designed a daggerboard-style adjustable draft rudder with a blowout safety feature. The rudder foil is set into a case with a non-destructive breakaway system that involves a moveable trailing edge tensioned with a shock cord. The boat can be sailed with the rudder fully extended, or in shallow water, partway up. This rudder configuration eliminates any chance of damage when grounding, while retaining a balanced helm at any depth of rudder setting, permitting shallow water control.

The Pole

Instead of a retractable pole that protrudes from one side of the bow, common to sportboats, we experimented with a pivoting pole that can be adjusted off-center up to 30° for better downwind performance. The bowsprit is hinged at the bow and attached to a cross-line at the base of the cockpit. This allows the spinnaker to be articulated from inside the cockpit.

With this final change complete, the i550 is now ready to take on The Everglades Challenge. We wish Meade and Jan, along with all the participants of The Everglades Challenge, the best of luck this year.

Anyone who is interested in building their own i550 sportboat may contact Watershed Sailboats at www.i550sportboat.com. Our WEST SYSTEM technical advisors are happy to assist anyone considering this project. Call us toll-free Monday through Friday 9-5 ET, 866-937-8797.