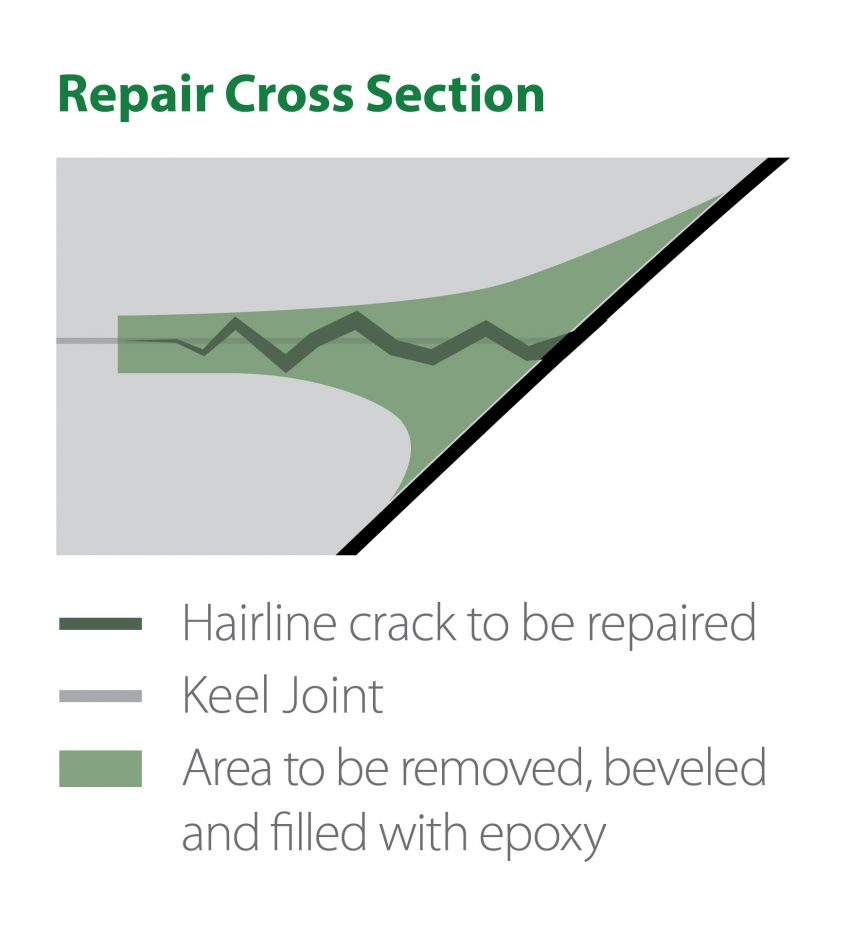

Repairing the ballast-hull crack

By Mike Barnard

For some sailors, there is a common maintenance ritual that occurs every spring—repairing the ballast-hull crack or cracks where the leading edge of the ballast keel meets the hull. This annually reoccurring crack is sometimes referred to as a “Catalina Smile” because it often occurs on Catalina sailboats. But we’re not here to pick on Catalinas because ballast-hull cracks are hardly exclusive to them.

The crack can form due to a number of causes but probably the most common reason is the hull isn’t as stiff as when it was new.

The thousands of fatigue cycles induced while sailing can leave the hull too flexible. This allows slightly more movement at the hull-to-keel joint, eventually exceeding the limitations of typical marine caulks and fairing putties causing the crack to return.

Many people try to fix this crack by fiberglassing over it, and it seems to work well… for about a year. Over a fairly short amount of time, the ballast-hull crack comes back because there is so much flexing that the repair laminate cracks and breaks. Instead, this repair should be done with a structural, yet flexible, epoxy: G/flex 655.

In the years since G/flex was introduced, we have had many customers (and employees) inquire about using it in this application. Year after year we recommend it, and year after year more sailboats are repaired like this. Several customers have used our method and been happy with the results. None of these ballast-hull crack repairs have had to be been redone.

Here is how we recommend fixing the ballast-hull crack or Catalina Smile

Open up the joint a bit with a Dremel tool or metal cutting saw blade to expose bright metal and fiberglass laminate. Once the crack is cleaned and widened, dispense G/flex 655 Resin and Hardener in equal lines on a plastic sheet (or 1.2:1 by weight) and mix by folding it over itself. Then begin applying it into the crack. The pot life of G/flex is 45 minutes, so unless a huge batch is mixed, there should be enough time to dispense it, although mixing multiple batches would give even more time. This combination has 32% elongation before breaking which helps to prevent cracks from reappearing on the joint. It can then be wet-sanded, dried, and painted for a lasting repair.