By Tom Pawlak — GBI Technical Advisor

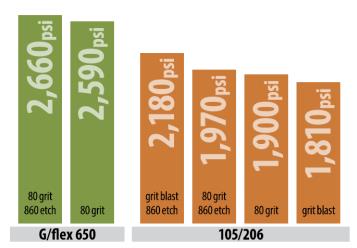

Because a newer epoxy formulation we offer is great for aluminum adhesion, we stopped offering the 860 Aluminum Etch Kit in the WEST SYSTEM product line in 2015. Before making that decision we ran a series of tests that compared bond strength of 105 Resin/206 Hardener and G/flex 650 Epoxy on aluminum surfaces prepared a variety of ways. As usual, we used the PATTI (Pneumatic Adhesion Tensile Test Instrument) to test aluminum adhesion.

In the charted data you’ll see that G/flex achieved the highest bond strength. Based on past adhesion testing, that is what we expected. From this data we concluded that 860 Aluminum Etch is not as important now as it was in the past. Prior to the development of G/flex Epoxy it was worth the time and effort to apply the 860 Etch because it improved adhesion of 105 Resin/206 Hardener by 371 psi over grit blasting alone. Given that G/flex adhesion to just abraded aluminum is greater than the bond to aluminum using 105 Resin/206 Hardener when abraded and treated with 860 Aluminum Etch, it would seem to make the 860 Etch Kit obsolete. In other words, if someone calls us and asks for our recommendation for gluing to aluminum, we will recommend grit blasting or sanding the aluminum with 80-grit sandpaper and choosing G/flex Epoxy as the adhesive.

860 Aluminum Etch will be on store shelves for a while until it is sold. After that, aluminum etching products are available at Aircraft Spruce as of this writing.