By Don Gutzmer – GBI Technical Advisor

“What Is the Shelf Life of West System® Epoxy?”

The short answer is: It depends, but usually a really long time.

…but you didn’t come here for just the short answer, did you?

One of the big advantages of WEST SYSTEM Epoxy is that the shelf life can be many, many years when stored properly. If you have used polyester resins, you’ll know that their shelf life is only about six months before it turns to a useless jelly-like substance. This is not the case with our WEST SYSTEM Epoxy. This stability of our 105 System and specialty epoxies makes it much easier to buy epoxy in larger quantities, at a more cost-effective price, to be used in a variety of projects, or just kept on hand for when the need occurs.

Expiration Date vs Minimum Shelf Life

We do not state an expiration date on our product containers. The epoxy doesn’t suddenly go bad and stop working due to old age. We do, however, sometimes state a minimum shelf life. The minimum shelf life is three years after the manufacture date for resins and two years after for hardeners. This minimum shelf life is solely based on how long we hold on to the retained samples.

Being an ISO 9001-2015, we keep a quality control sample from each batch of resin and hardener that we manufacture. This sample undergoes a strict quality control process to ensure the product will perform as expected once it leaves the facility. After testing, this sample gets stored in a controlled environment for two to three years, depending on whether it’s a resin or a hardener. This allows us to pull to an actual sample of the material from that exact batch (that has been properly stored) should any customers ever have an issue within that timeframe.

What Happens Beyond Two-Three Years?

The bad news: We no longer have a retain.

The good news: It should still be just fine for most general applications. You just need to do a simple test.

If a customer calls beyond that two-three year window, we would recommend they mix a test batch to ensure the epoxy cures within the specifications on our technical data sheets. This would tell you if there was some sort of contamination to either the resin or hardener. For any critical structural applications, we recommend using a hardener that is no more than two years old to be safe. Otherwise, as long as the test batch is successful, the epoxy will work fine for most general applications.

How Do I Determine the Manufacture Date?

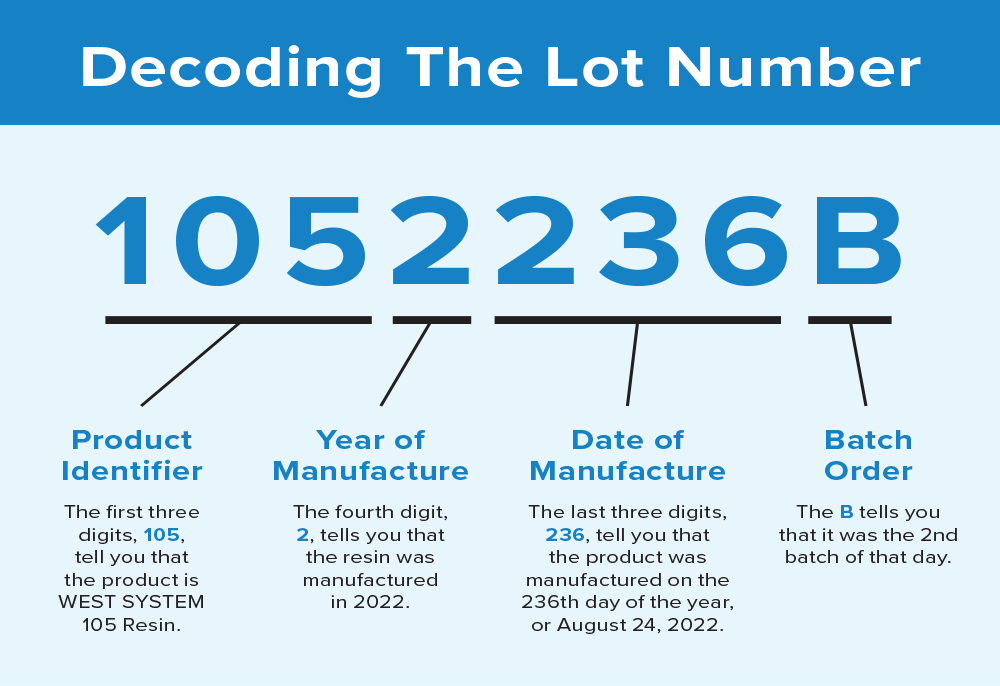

All WEST SYSTEM® Resins and Hardeners are identified with a lot number comprised of seven numbers followed by a letter. You can determine the date of manufacture by decoding the lot number.

- The first three digits identify the product.

- The fourth digit identifies the year of manufacture.

- The last three numbers are the date of manufacture, expressed as a Julian Date. These numbers can range from 001 to 366. 001 would indicate that the date of manufacture was January 1. 366 would indicate that the date of manufacture was December 31, in a leap year.

Shelf Life for Critical Structural Applications

For critical structural applications we recommend using resin that is less than three years past the date of manufacture and hardener that is less than two years past the date of manufacture. The resin and hardener should be stored in its original sealed container. The mixed epoxy can certainly still achieve full strength properties well after these dates, however the likelihood of contamination being present increases the older the epoxy gets and if the product has been opened and used for other projects previously.

These time frames are applicable to the 105 System as well as our specialty epoxies (G/flex®, Six10®, and G/5®). Our fillers and additives are good for an indefinite amount of time, provided they stay contaminate free.

Understanding Older WEST SYSTEM Epoxy

The reason why we are a little vague on giving an exact shelf life is that the epoxy can be useable for many years, depending on the application. We’ve tested epoxy over 10 years old that cures without any issues. There are some traits that will change over time, purely due to age, that you should be aware of:

- Physical properties will reduce slightly, therefore it’s always best to use fresh product for critical structural applications.

- The hardener can darken in color. The 205 Fast Hardener® and G/5 hardener are known to sometimes darken to a reddish-purple. Though it is purely a cosmetic issue, it does sometimes surprise people.

- Increased viscosity of the resin is the primary change in the handling characteristics of older epoxy.

When resin has a higher viscosity due to age, it becomes more difficult to meter and mix properly. If you warm the resin, it will help lower the viscosity and make it easier to handle. We recommend spending additional time mixing to ensure the resin and hardener are thoroughly blended.

Prolonging the Life of WEST SYSTEM Epoxy

Temperature fluctuations during long-term storage can make resin susceptible to crystallization. The ideal storage temperature is above 50°F (10°C). Fluctuations below that 50°F (10°C) threshold promote the growth of epoxy crystals. The resin is much more tolerant of heat, and it can withstand storage at 100°F (37°C) without a problem.

Crystallization

Crystallization can make the resin thicker and can make the resin appear milky or cloudy, but don’t worry! The process of crystallization can be reverted by simply heating the resin to around 120°F (49°C). The simplest approach is placing your container into warm water and occasionally gently stirring within the container until all the crystals disappear. If heavily crystallized, they can take several hours to disappear.

Another issue with aging products is moisture contamination. If hardeners are left open, they can take on moisture over time. The moisture will act as an accelerator and make the epoxy foam when curing. It’s best to store your epoxy with the cap secure to prevent contamination.

How Should I Test My Older Epoxy?

You can do a simple test to see if your epoxy is still good. We call this a pot life test. For a pot life test, you want to mix 100 grams (or 4 fl.oz.) of epoxy (total resin and hardener) in a 2″ diameter container.

Start your timer and mix the epoxy for two minutes. At the two-minute mark, stop mixing, but leave the stick in the container. As you get close to the expected gel time, move the stick to see if the epoxy flows back into the depression left by moving the mixing stick. Repeat until the epoxy no longer flows back into place. This is considered the gel time. This is when you would stop your timer.

Things to Consider When Testing:

The frequency with which you test the epoxy will vary with the speed of hardener you are working with. On the WEST SYSTEM Technical Data Sheets, we provide pot life values. These can be used as a guide to determine when to start checking if the epoxy has gelled, and ultimately whether the epoxy passed the test. If your test time is slightly off, your epoxy is still fine to use for general applications. If the gel time is drastically different, or foams, you will probably want to discard it.

Our test is performed with 100 grams (4 fl.oz.) of epoxy at 72°F (22°C). Keep in mind that temperature will dramatically affect the result of a pot life test. An increase in temperature of 18°F (10°C) above 72°F (22°C) will cut the pot life time in half.

What’s the Takeaway?

Though the minimum shelf life is only a couple years, WEST SYSTEM Epoxy can have a very long shelf life when properly cared for. Keeping your epoxy in a relatively warm environment, in sealed containers will prevent two of the biggest issues that affect epoxy’s lifespan: crystallization and contamination. Looking after your epoxy will keep it useable for many projects to come.

To learn more about WEST SYSTEM products, visit westsystem.com.