Home-built camping trailers

By Mike Lance

These two trailer projects came about after my good friend Orrin and I had been messing around with WEST SYSTEM products for the past forty years. After building and racing a hydroplane in the Seventies, we built a 21′ cedar strip two-person kayak in 1980 and an 18’6″ cedar strip canoe in 1981. In 1981 we placed second in the 320-mile canoe race across New York state using our kayak. Both boats are shown in May/June 1985 edition of The Boatbuilder, Gougeon’s precursor to Epoxyworks.

After I had competed in the Sikaflex® Challenge races over a number of years, a book on teardrop trailers caught my interest. Having some plywood leftover from the Seventies I started thinking that I could build a small camping trailer for my wife and me. There existed a real problem: would my wife actually sleep in something this small? With encouragement from my daughter, Karen, to build it for the sheer fun of building, I mentioned the idea to my wife, Terry, saying that I would understand if she declined. Her response: “How dare you try and exclude me from your next adventure?” Game on.

The “Go-Lo” Trailer

Construction started with an eight-foot utility trailer from Harbor Freight Tools. My very talented neighbor, Tom, did all the necessary welding. This included raising the bed of the trailer 3″ for road/tire clearance and moving the front part of the frame 15″ forward as it would be in the way of people entering the cabin. With the welding done, a 5/8″ plywood deck was fastened to the steel frame. Time now to mix up some WEST SYSTEM 105 Resin/206 Slow Hardener and start constructing the walls.

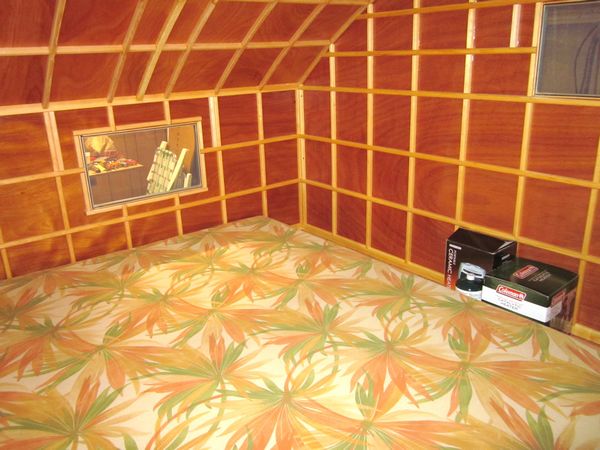

The four walls were built with select eastern white pine and 4mm okoume plywood. Each top frame piece was built using two pieces of Sitka spruce, 3/8″ thick by ¾” wide. Steaming was not necessary since the curve was gentle enough for the glue to hold the piece in shape when it came out of the jig. The door, vent, and windows were made from scratch. After the portable toilet and fold-down sink were installed and the electrical work was completed, all that remained was the painting. Two coats of 105/206 were applied to the outside with a quick sanding between coats. Sanding was needed again after the second coat. The owner of a small collision shop allowed me to work with him on final sanding and taping before he sprayed the primer and the final coats.

The “Go-Lo” trailer, as we call it, cost $4,200 to build and weighs 840 lbs. This concluded my construction of trailers, or so I thought.

The Teardrop Trailer

My daughter and her husband visiting from Seattle one Christmas saw it and liked it. The next Christmas my son-in-law, Thadd, commissioned me to build one for them. They have two young daughters and wanted a true teardrop trailer, not one with 6′ of headroom.

So, how do you squeeze two active kids and two adults into an even smaller trailer? The answer was a trailer with a slide-out unit.

Some key differences would be necessary with the second trailer. I couldn’t ask Tom to do all that welding again, so I started with a more expensive Sure-Trac trailer. Thadd loves to cook, so the galley in the back includes a sink, lift-up counter, and a reversible table for the stove or for outdoor snacks at night. The sharper curved top required steaming the ribs for the roof. To save time, I purchased a fan, door, and window. The second trailer cost $6,800 and weighs 1,020 pounds. The teardrop does not have a potty, but they are young and sleep through the night. Now I am certainly done building trailers, but I will never be done using WEST SYSTEM Epoxy.

That became apparent 35 years ago on a golf course when my wooden three-wood shattered into three pieces. I used 105/206 to glue it back together. It’s the best club in my bag today. Clearly, I build and fix things better than I golf.