by Jim Derck

Why do centerboards and rudders need durable edges? When centerboards and flip-up rudders drag across the bottom, the first fiberglass to abrade away is usually the leading edge at the bottom. This exposes the end grain of the wood, allowing water to be absorbed the length of the centerboard or rudder. The wood then expands, cracking the fiberglass along the leading edge and causing more problems. When it is time to repair the tip, it usually takes a long time to dry the wood for an effective repair.

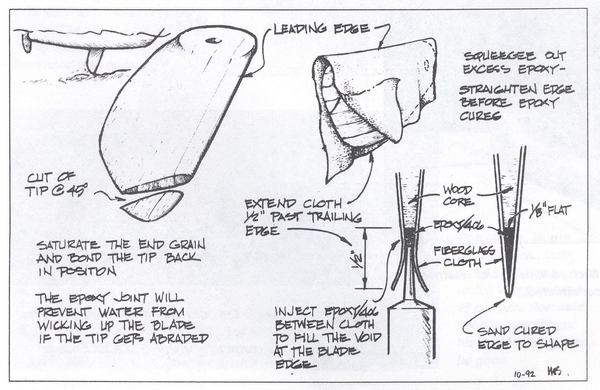

To isolate the end grain before applying the fiberglass, cut diagonally from the leading edge to the bottom, apply several coats of epoxy to both pieces, and bond the tip back on. In the future, if the fiberglass cloth abrades away and the wood gets wet, it is quick to dry out the short length of end grain prior to making the repair.

Here is a technique for fiberglass covering that has proved over the years to provide a long-lasting trailing edge. When rebuilding an existing blade or before applying fiberglass cloth to a new blade, plane a flat on the trailing edge about 1/8″-wide (wider for large rudders and centerboards). When applying the fiberglass cloth, position the rudder or centerboard horizontally so the leading edge is up. Drape the fiberglass over the foil and trim so that it extends 1/2″ past the trailing edge. If you make a full-scale drawing of the trailing edge of your board or rudder, you will get a better idea of exactly how much fiberglass cloth to leave.

After the fabric is wet out, use an 807 Syringe to apply epoxy thickened to a non-sag mix with 406 Colloidal Silica to fill the gap between the two layers of fiberglass cloth.

Squeegee out excess epoxy and align the trailing edge so that it is straight. If necessary, clamp a plastic-covered straight edge in place to make the fabric conform to the shape of the trailing edge. After the epoxy cures, do the final shaping with a sander or sandpaper and a block of wood. Use caution, the edge can be very sharp!

For more information on constructing centerboards and rudders, see How to Build Rudders & Centerboards.

Editors note: G/flex epoxy, which had not yet been formulated when this article was originally printed in 1992, is an excellent choice for adding durability to the edges of centerboards, rudders, and paddles.