by Brian Knight—GBI Technical Advisor

Bud Hauschild, from Hastings, Michigan, sent us this idea for a drill guide used to accurately drill holes through irregularly shaped surfaces. Additionally, you can use this guide to drill from both sides of a thick beam and have the holes line up. Orthopedic surgeons use a similar device to drill holes in bone for screws or pins.

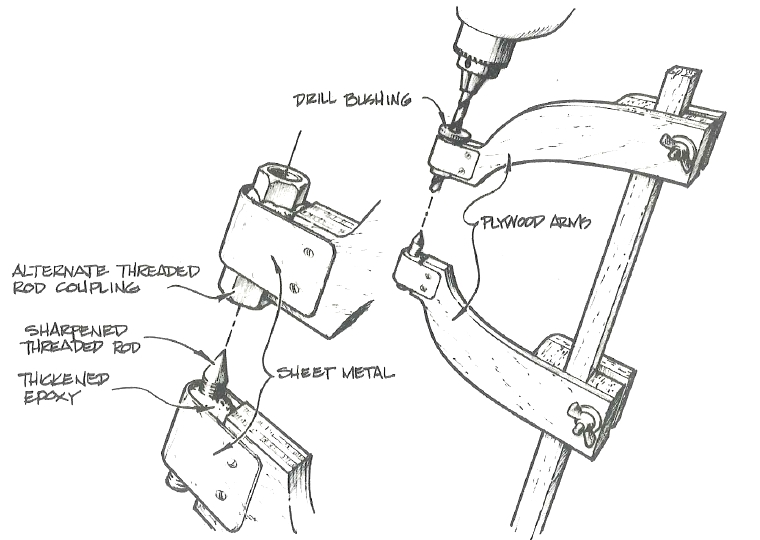

Bud’s guide consists of two identical curved arms mounted on a slide rod. A pointer tip is epoxied to one arm and a drill bushing is epoxied to the other arm in line with the pointer tip. They look like giant calipers.

To use the guide, you place the pointer where you want the drill bit to emerge from the work and locate the drill guide where you want the bit to enter. When the hole is drilled, it will be located exactly where you anticipated.

Make the slide rod out of a piece of straight scrap wood of rectangular or square cross section. Build the curved arms using scrap 1/4″ or 1/2″ plywood. Attach them to the slide rod as shown in the drawing.

Bud used sheet metal and thickened epoxy to mount the pointer and construct the socket for the drill bushing. He cut a small piece of metal from a coffee can, bent it to form a sleeve large enough for the pointer or drill bushing to fit inside, and bolted it to the plywood arm. He filled the sleeve with thickened epoxy, inserted the pointer and drill bushing into the wet mixture, and allowed the epoxy to cure.

To build a slightly more versatile (albeit slightly more expensive) assembly, bond a ½”dia. threaded rod coupling (20 tpi) to the end of each arm with some scrap fiberglass cloth and epoxy. Grind a point on the end of a bolt or short piece of ½” threaded rod and screw it into the insert on one of the arms. On the other arm, screw an appropriate drill bushing into the coupling. Threaded drill bushings in several different sizes are available from Rockler Woodworking & Hardware.

Threaded rod couplings are available at many hardware stores, although the fine thread coupling might have to be special ordered.

To use the guide, slide the arm with the pointer to a convenient location on the slide bar and lock it in position. Place the pointer where you want the drill bit to exit and slide the arm with the drill bushing to the location where you want the drill to enter. Lock this arm to the slide bar, insert the drill bit into the drill bushing, and drill the hole. If you need a hole larger than the capacity of the drill bushing, first drill a small hole to create a pilot and then enlarge it with the proper size bit.