by William D. Bertelsen

Ticonderoga is a 220 ft. sidewheel steamboat built in 1906. She carried passengers on Lake Champlain until 1953. The Shelburne Museum wanted to replace the decks and cover them in a way that recreated the appearance and texture of the original canvas sheathing. But it was equally important that the authentic looking decks be durable enough to survive the unrelenting foot traffic inevitable for such a magnificent museum centerpiece.

Of particular concern was the threat posed by high-heel shoes. The restoration team, led by Chip Stulen, wanted to cover the new, clear-vertical-grain douglas fir deck planking with two layers of 3-mm okoume laid in opposing diagonal strips. The okoume, a relatively soft, delicate wood, had to be protected without sacrificing the authentic look. Part of the solution was WEST SYSTEM® 105 Resin and 206 Slow Hardener. It could be used to wet out and apply a textured reinforcing fabric to the surface. But which fabric and how many layers would provide adequate protection for the least amount of time and money?

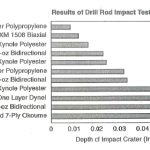

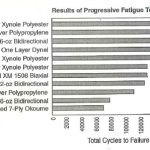

The Shelburne Museum contacted our technical staff for advice. They asked the Gougeon lab to evaluate the fabrics Shelburne considered most likely to meet the need without busting the budget. The candidates were: 6 and 12-oz. bi-directional E-glass fabrics, 15-oz. biaxial E-glass fabric with 3/4-oz. mat, 4-oz. Polypropylene, 3.6-oz. Dynel, and 4-oz. Xynole Polyester.

Jim Derck of the Gougeon technical staff constructed the test specimens using 7-ply okoume plywood as the substrate. He hand wet-out various combinations of the fabrics and squeegeed them onto the okoume surface with WEST SYSTEM 105/206 epoxy. He deliberately left the fabric weave of the outer layer incompletely filled to afford a comfortable, grainy walking surface. He also made a point of weighing the 6″ x 6″ okoume blanks before and after fabric application, so that it would be possible to calculate the weight of epoxy required to apply each type of fabric. I later compiled some surprising statistics on the excessive “thirst” of some fabrics for epoxy. More on that in a future article.

To estimate the resistance of each deck preparation to high-heel shoe traffic, I subjected the specimens to two types of tests. In one test, the sample was placed on a concrete floor and subjected to the impact of a 3/8″-diameter steel drill rod dropped from a height of four feet. The rod weighed 1.41 lb. and was guided by a vertical PVC tube to assure a consistent, perpendicular impact. The rod was ground flat on the striking end. I quantified the impact resistance by simply measuring the depth of the resulting crater.

The other test, a progressive fatigue test, utilized the repeated-load capabilities of the newest MTS servo-hydraulic test machine in the Gougeon lab. These tests could be called “repeated prodding” using a flat-ground, square-section (3/8″ x 3/8″) steel spike. The spike was clamped securely in the grips of the test machine so that it would make perpendicular contact with the surface of each specimen. The controlled force of the test machine could thus be concentrated on one tiny area of each specimen via the spike. The machine was programmed to make the spike load rise and fall smoothly with the passage of time like the undulation of a sine wave. The prepared specimen surface would undergo five complete load repetitions every two seconds.

I conducted the fatigue tests using a stress ratio of 0.1. That means the minimum load on each cycle was 1/10th of the peak load value. All tests were begun with a 200-lb. peak load on the spike. Since the cross-sectional (contact) area of the spike was only 0.141 square inches, the initial maximum contact pressure would be 1,419 psi. I programmed the test machine to increase the peak load by 0.1% of that value (by 0.2 lb. or 1.41 psi) every 100 cycles. The effect was to double the original peak load after 100,000 cycles. I stopped each test when the impression in the surface of the test sample reached a depth of 0.031 inches (1/32″). The spike administered a concentrated load which grew larger with every 100 repetitions, so only the most durable surface preparations survived beyond 130,000 cycles.

You will find the results of the impact and fatigue tests presented in the accompanying bar graphs. The performance of the various combinations in each event are listed in rank order, with best performers at the top of the list.

Using the test results, the Shelburne Museum was able to make an educated decision rather than a blind guess in choosing the appropriate materials for their worthy project. The TICONDEROGA test series is another good example of how the technical staff, backed by the Gougeon lab, can help customers to do better work with WEST SYSTEM products.

Photos courtesy of the Shelburne Museum.