by Jim Derck—GBI Technical Advisor

After living in our house for eight years and watching the ends of the threshold slowly deteriorate away and a few cracks and checks develop, I decided to replace the storm door, and figured now was a good time to restore the threshold.

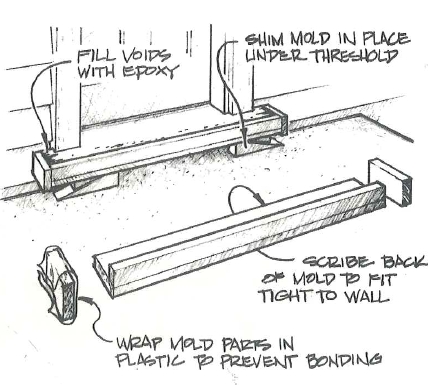

To make it easier to control the shape of the repair, I built a simple female mold. I made a one-piece mold to make it easier to prop in place, but a small mold for each end would have worked just as well. As I cut each piece for the mold I wrapped it in Polyethylene plastic (garbage bag plastic) so the epoxy would not stick to it.

I waited for dry weather to make sure the wood was very dry. Using a rasp, I removed loose fiber from the ends of the threshold. Because the cracks and checks were quite small, I opened them up with a chisel to make it easier to apply the epoxy. I coated the end grain and the cracks and checks with a mixture of 105 Resin and 206 Slow Hardener. I kept applying the epoxy until the ends of the threshold stayed glossy. I added 406 Colloidal Silica to make a non-sag mix and applied this to the inside corners of the mold. I smeared some thickened epoxy around the end of the threshold and propped the mold in place under the threshold. I poured epoxy into the ends of the mold to fill any remaining spaces. With a putty knife I finished filling the cracks with thickened epoxy.

After the epoxy cured hard, I removed the mold. With a file and sander I did a little final shaping. I painted the repaired threshold, and a year later it still looks like new. I only wish I would have made this repair years ago!