by Brian Knight—GBI Technical Advisor

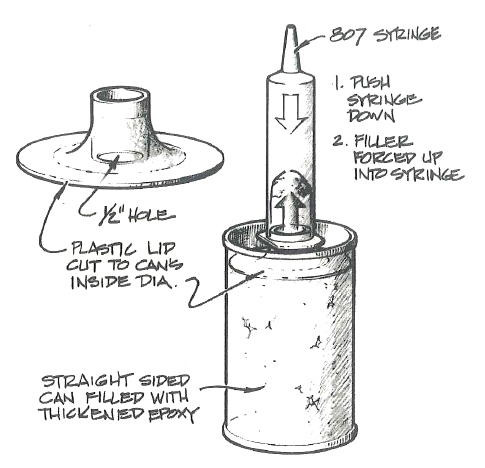

WEST SYSTEM® 807 Syringes are handy for injecting epoxy into hard-to-reach areas, but it’s difficult to load the syringe with thickened mixtures that won’t pour into the syringe body. With this gadget, loading non-sag mixtures is easy. It consists of a flat plastic disc with a short length of PVC pipe bonded over a hole cut in the center of the disc. Push the disc down in a container of thickened epoxy and epoxy is forced out through the hole in the disc, through the PVC tubing, and into the syringe.

Make the plunger with smooth plastic for easy cleanup. I used the plastic lid from an empty WEST SYSTEM filler can. Trim the edges from the lid with a utility knife to make a flat disc and drill a 1/2″ hole in the center. Bond a short piece of 1/2″ PVC pipe to the plastic disc over the drilled hole, using epoxy thickened with 406 Colloidal Silica to make a fillet between the pipe and the plastic disc. Since the outside diameter of 1/2″ PVC pipe is about 5/8″, the syringe body fits snugly over it.

Unless you properly prepare the surface, epoxy won’t stick very well to the plastic disc or the PVC. Begin the preparation by cleaning the surfaces of the disc and the pipe with a solvent and paper towel to remove any contamination. Lacquer thinner, acetone, or denatured alcohol will do an adequate job. Then heat both the disc and the PVC tube with a propane torch. When the plastic has cooled, set the PVC pipe over the hole in the plastic disc and bond it to the disc with a fillet of thickened epoxy. Leave ¼” of the pipe extended above the fillet. The syringe body will fit snugly over the pipe.

After the epoxy has cured, use scissors or a utility knife to cut the plastic disc to fit inside the container you have selected. Use a small, straight sided can that doesn’t have stiffening ridges formed in the sides (like a tomato paste can or a small juice can). If you cut the disc carefully, there won’t be too much filler squeezing past the edge of the disc when you press down on the assembly.

To use the syringe filler, mix a batch of thickened epoxy in a mixing pot and transfer it to the can. Set the plunger inside the can on top of the filler, place the syringe body over the PVC tubing and push down. This forces the thickened mixture out of the can and into the syringe. Since it is easier to put the mixture into the can than the syringe, filling the syringe goes quickly.

Clean the can and the plunger with lacquer thinner, acetone, or denatured alcohol when you have finished the project. A small tomato paste can will hold enough thickened epoxy to fill an 807 Syringe three or four times.