By Bruce Niederer — GBI Technical Advisor

In the previous issue of Epoxyworks, we looked at the start up process employed by the craftsmen at Van Dam Custom Boats as they built LUV N IT, affectionately referred to as the Limousine in Van Dam Custom Boats-Part One. We ended our “tour” of this build with the hull stained and pre-coated with WEST SYSTEM® 105 Resin/207 Special Clear Hardener, and the custom-built stainless steel cutwater being fitted for installation.

Let’s pick up the build with the cabin top being installed…

Our photo gallery picks up this build with the cabin top being installed and ends where the boat is delivered to its proud new owners.

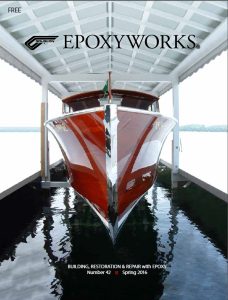

Cover Photo: Nokomis, the sister ship to LUV N IT. Photo credit: Michel Berryer