by Brian Knight—GBI Technical Advisor

Rectangular or square edge strips tend to get out of alignment between mold stations, especially where the bend is tight and the planks have to be forced into position. You can build intermediate mold stations in these areas to support the planks in more places.

Tom Pawlak of our Technical Staff maintains plank alignment another way. When he had problems aligning thin planks, he drilled a small diameter hole vertically through the strip. Then he broke one end of a toothpick (the round, tapered kind) off and stuck the pointed end into the hole. He forced the plank into position and tapped the toothpick into the plank below, like a wooden nail. Tom suggests that you over-align the planks because there is some slop in the system from the taper on the toothpick.

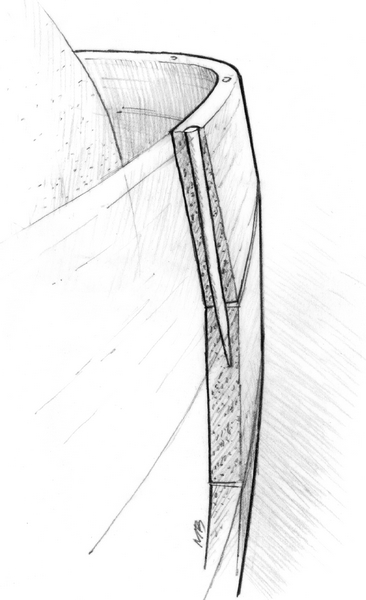

On thicker planks, use dowel rods glued in pre-drilled holes. It is a good idea to use a drill bit a few thousandths of an inch smaller than the dowel. The friction helps to draw the planks together.

You can also fasten edges with metal fasteners, but inevitably a couple of fasteners will break through one of the planks. Metal fasteners are hard to remove and equally difficult to fair smooth. On the other hand, wooden dowels that break through the surface are easy to fair.