The right epoxy resin tools for the job

By Avery Jorgensen, GBI Composite Materials Engineer

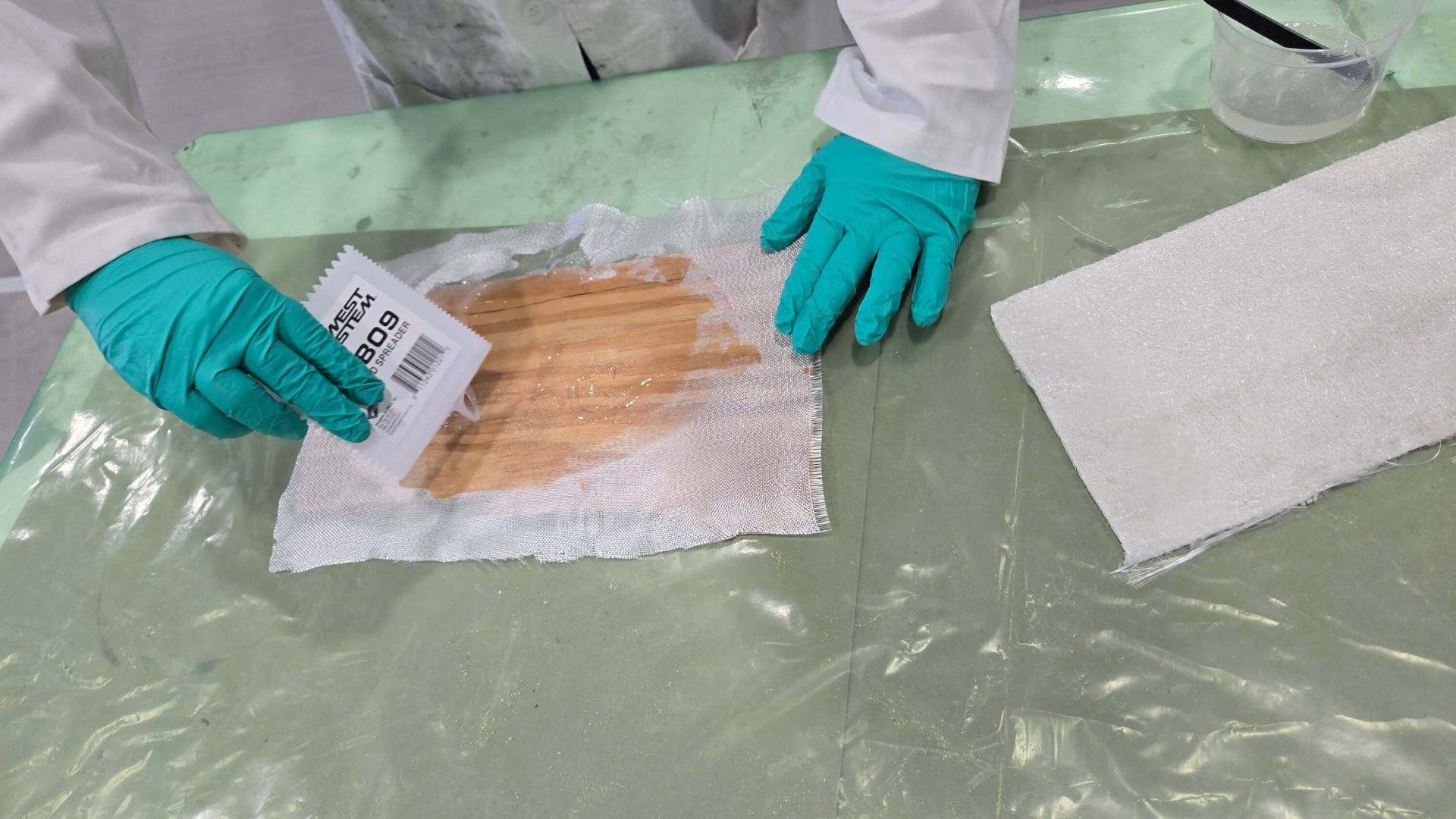

Wetting out fabric is very important when making or repairing any composite part. Encapsulating each fiber in resin assures the highest level of strength and durability possible. Most of us do it without thinking about what the best way might be—even I catch myself using the wrong instrument for the job sometimes. This article could help you speed up your process, make your laminates more consistent, or even save you a bit of money.

There are so many different wet-out tools, and searching online brings up hundreds of results. This article will go over several different epoxy resin tools, when we recommend using them, and when it is okay to just start going at it with your gloved hands.

What does wet out look like?

In order to select the best tool for the job, we need to understand what a properly wet-out reinforcing fabric looks like. A wet-out reinforcing fabric is one in which every fiber is coated in epoxy. When the epoxy fully encapsulates the fibers, loads can be evenly distributed among them. The fibers are much stronger than the resin, so if that load is not distributed to the fibers, the resin can fracture, and the composite may fail.

When working with fiberglass, you can easily tell when the fabric is fully saturated. As the fiberglass gets wet, it becomes translucent, which makes it easy to see. In contrast, carbon fiber looks the same when wet as it does when dry—both appear black. As you push the epoxy into the small gaps in the reinforcing fabric, air bubbles rise through the epoxy and pop. The popping sound indicates that air is being forced out.

Our Fiberglass Boat Repair & Maintenance manual describes wet and dry application methods for wetting out reinforcing fabrics. One effective technique for working with heavy fabrics is called back wetting, which combines both wet and dry methods. First, lay the fabric out dry and then fold it back onto itself. Apply epoxy to the backside of the fabric. When you flatten the fabric again, the epoxy pushes through the backside, rather than applying it from the top down as in the typical wet method. This approach makes it much easier to saturate the fabric.

Spreaders & Squeegees

Our 808 Reusable Flexible Spreaders are an inexpensive and effective method of moving epoxy. They enable you to apply pressure to the weave to allow the infill of the yarns. Holding the spreader at a low angle makes it particularly effective at filling the yarns. Spreaders are an ideal epoxy resin tool if you are applying a lightweight fabric to a hard and smooth surface.

Spreaders are helpful when making a surfboard or applying 4 oz fabric to a cedar strip canoe. They also work well for fairing repairs after you have finished glassing. Using one of these plastic spreaders on thicker 17 oz fabric is possible, but it will take a long time, and your hand might start cramping before you finish. Any fabrics heavier than that are difficult to fully wet out with just a plastic spreader, leaving dry fibers and stress concentrations in any repair or part you are making.

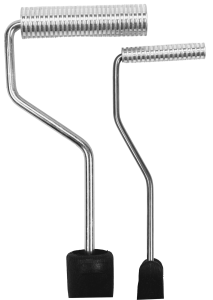

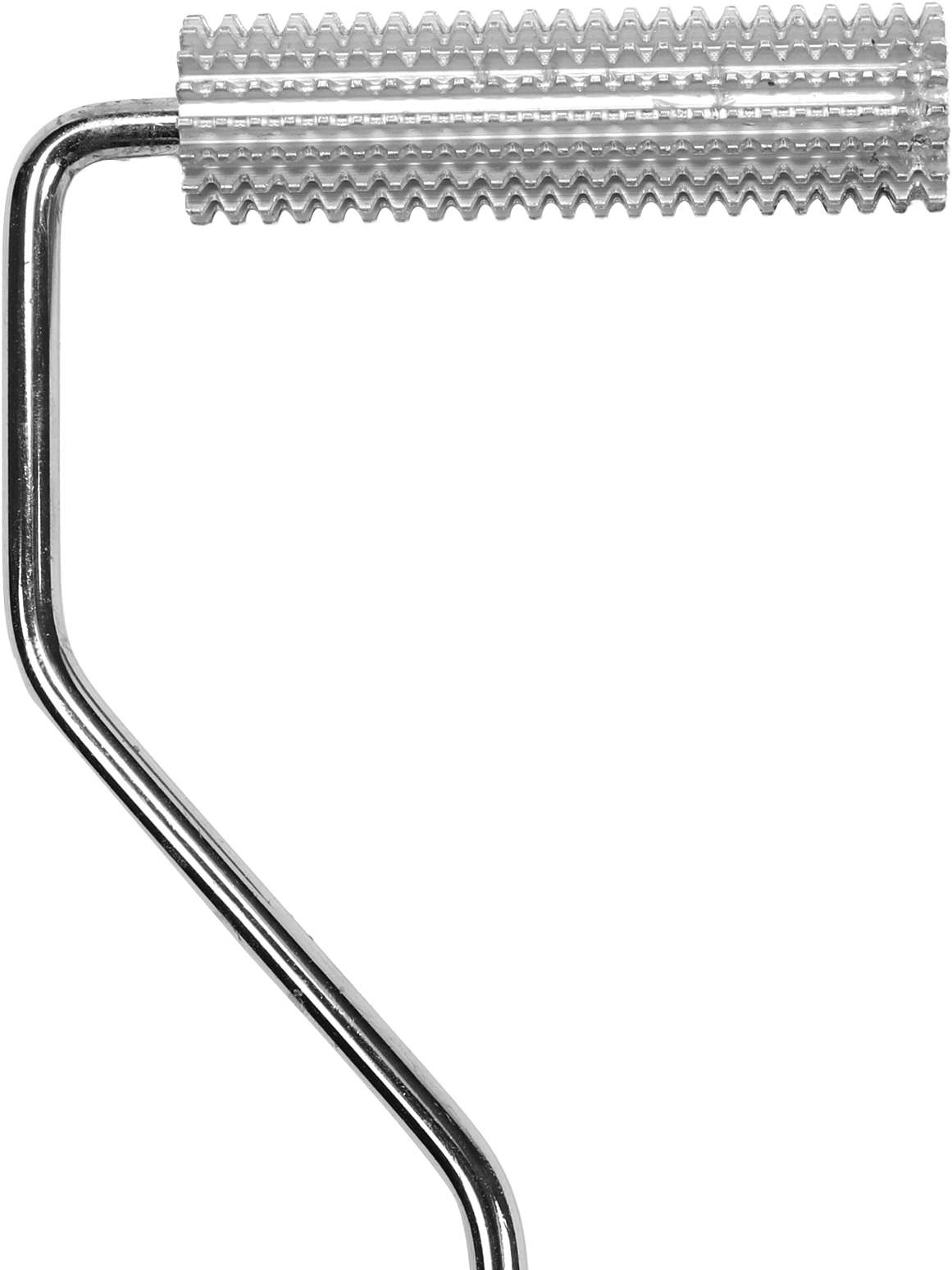

Serrated Rollers

Serrated rollers are typically metal, usually aluminum, with deep grooves in them. This means they are substantially more expensive than plastic spreaders but still reasonable. These are particularly useful epoxy resin tools when wetting out heavy fabrics, especially if you have multiple layers of heavy fabrics. The serrations help focus your downward force into a more concentrated area and the grooves allow air to escape. This allows the epoxy to penetrate deeply into thick fabrics. These can move quickly over thick fabrics but begin to skid and slide when used with thinner fabrics.

While plastic spreaders work well on thin fabrics, using alternative tools is often more efficient. Although many people treat plastic spreaders as disposable, I prefer not to buy new rollers every time I need to wet out fabric. Therefore, I find it important to keep them clean. You can do this by disassembling them and wiping them down with acetone, lacquer thinner, or denatured alcohol.

Corner Rollers

Although corner rollers are unnecessary for wetting fabric, I felt I should mention them. They are often available in a kit with other rollers and are made of metal, featuring several differently-sized wheels. Nothing gets into a corner like these, especially in hard-to-reach places like under a bench or in a cabinet. These tools primarily press pre-wetted laminates into challenging corners, ensuring that no air gaps remain. These provide the same mechanical advantage that the serrated rollers do by focusing the downward force of your arm into a small area, greatly increasing the pressure. Because these are so narrow, it would take way more time and effort to use one of these guys to wet out any considerable amount of fiberglass.

Bristle & Knob Rollers

Bristle and knob rollers take that mechanical advantage and dial it up to 10. The applied force now focuses on either the points of the knobs or the tips of the bristles on several small metal strips. These typically saturate very heavy fabrics or chop strand mats. While we don’t recommend using epoxy with chop-stranded mats, this is what we would use if we did. Using a thick fiber with bristle rollers enhances application on porous surfaces. The bristles can penetrate the foam carrying the epoxy with it. This helps create a mechanical bond between the core and the laminate. However, they work well for thick fabrics and mats, and they work just as poorly on light fabrics. They don’t move the epoxy around nearly as well as a plastic spreader.

Hands

Hands are a great tool, and I’m pretty attached to my set. They are an excellent tool for lifting and manipulating fabric, which helps ensure that specific areas receive adequate wetting. Even though they don’t provide the even pressure like a roller or plastic spreader would, but they will certainly do in a pinch. They won’t penetrate as deeply as any rollers, but hey–they’re free! Finally, they won’t put fabric into the corners or corner rollers, but they are certainly better than nothing. Like all tools that aren’t disposable, you should do everything you can to protect them. When working with epoxy, wear gloves and cover any exposed skin that may get epoxy on it.

Wrapping Up

Consistently and thoroughly wetting out your fibers is one of the most important aspects of composite repair and fabrication. Plenty of epoxy resin tools could aid this process instead of simply using your hands. Plastic spreaders and squeegees are great for light fabrics on hard surfaces when moving epoxy around is the most important thing. Serrated rollers help force the epoxy into thicker fabrics by concentrating the force of your rolling. Corner rollers help move fabric where it needs to go, but are too small for wetting fabric out. Finally, bristle rollers and knob rollers increase the applied pressure and force epoxy into very thick fabrics.