By Hugh Horton

Braided Kevlar®, or composites with Kevlar and carbon braid, are used for joints and many components of my sailing canoes. These include the hull/deck joint, cockpit coaming and spray deck rims, the leeboard bracket and retaining pin, the attachment of the mast step to the hull, the gunter’s yard heel fitting, and the seat and its major parts. (My source for Kevlar braid is A&P Technology, 4595 East Tech Drive, Cincinnati, Ohio 45245-1055, phone 513-688-3200. Their website is www.braider.com.) The techniques shown here can be adapted to many other projects.

Because of the variety of Kevlar and carbon braids available, forming intricate shapes is easy. However, after Kevlar has cured, shaping is difficult because of its toughness. Tools and abrasives must be kept sharp. Here’s how I did it.

Building the cockpit rim

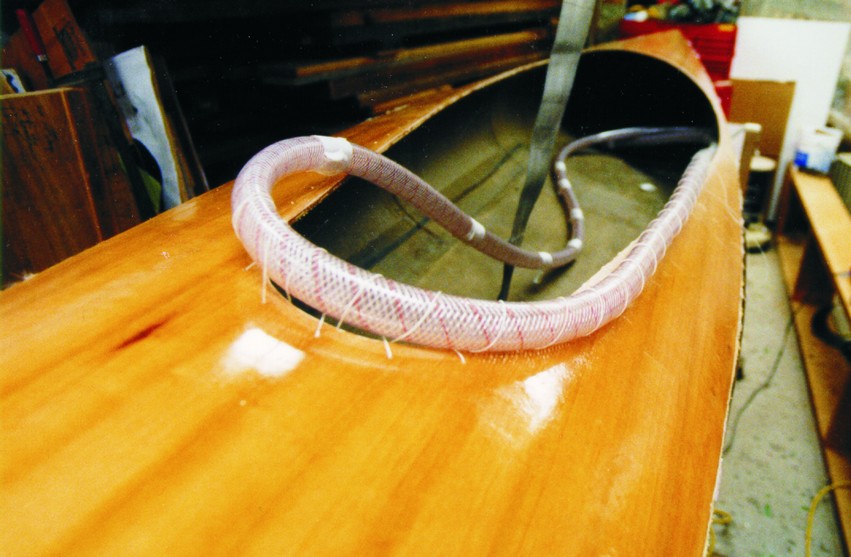

A hose is used as a mold. I pick a hose that is smooth, 1 1/8″ to 1 1/4″ in diameter and capable of bending fairly. I precisely layout the cockpit opening and fair the cutout as perfectly as I can. I round over the underside edge of the deck, although this is difficult because of the layer of kevlar. It is very important to align the hose precisely, getting it exactly at the edge. I lace the hose in position with marline, a fine thread that is strong enough to pull tightly. (Top image)

Building the leeboard bracket

The leeboard bracket is designed to transfer all of the side loads of the board through the hub and into the hull without being permanently attached to the hull. I used the hull as a mold to get perfect alignment of the attachment points.