For Good Adhesion

by Brian Knight—GBI Technical Advisor

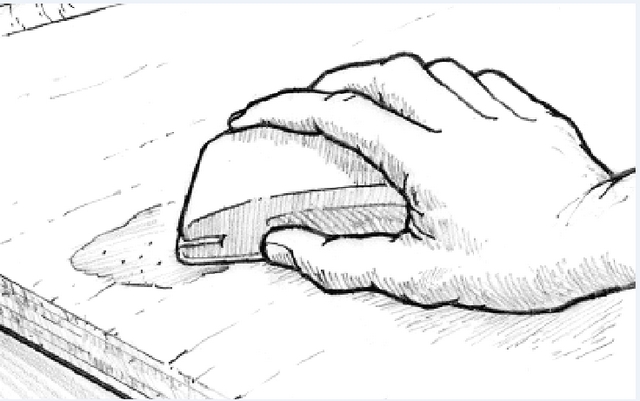

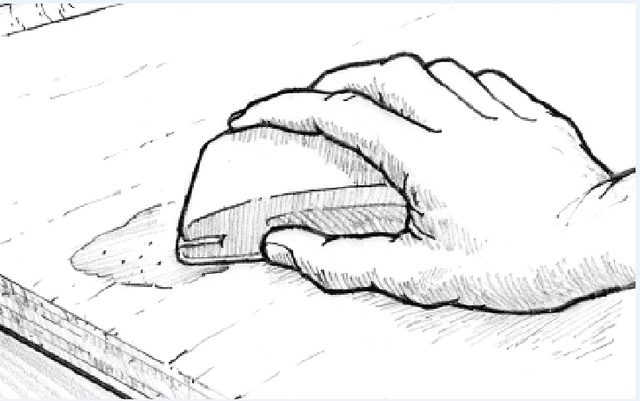

Above: Sanding the bonding surface is important to good adhesion with epoxy.

“Cleanliness is next to Godliness,” the old expression goes. This is certainly true when preparing a surface for an epoxy application. The surface has to be clean to begin with or there may be adhesion problems. But often, our good intentions with respect to cleaning a surface result in contaminates deposited on the surface. Below are some potential surface contaminates, ways to avoid them, and an almost foolproof method to determine if a surface is clean or contaminated.

Oil, grease, wax, etc.

Generally speaking, there is no good reason to wipe a surface with an organic solvent unless there is good evidence that an organic contaminate is present on the surface. We are all familiar with solvents like acetone, lacquer thinner, and proprietary mixtures like DuPont Prep-Sol™ that are made to remove specific contaminants. Most solvents of this type will remove organic contaminants such as oil, grease, wax, etc. So wiping a surface with an organic solvent may seem like a great idea. However, the solvents are also capable of dissolving contaminates from rags and depositing them on the work surface. This is not good. For example, silicone is a well-known mold release and incidentally an ingredient in many home laundry fabric softeners. We know of many instances where a surface was contaminated by silicone that was extracted from a rag by a solvent. In addition, many organic solvents are capable of dissolving man-made fibers found in rags. Your wipe down with acetone could be depositing plastic on the surface you are trying to clean. These dissolved plastics can act just like a mold release.

If you suspect a contaminated surface and you need to use a solvent to remove it, use plain white or unbleached paper towels to wipe the solvent on, and fresh paper towels to dry the surface. Do not use rags. To avoid re-depositing the contaminant on the surface, wipe the solvent off while it is still wet. Change paper towels frequently both for the wipe-on operation and the drying operation.

See Surface Preparation in the WEST SYSTEM User Manual.

Sanding dust

Despite the dust, a freshly sanded surface is about as clean as a surface can get, but there is always an urge to rub your hand over it to check for smoothness. This is not a good practice unless you are wearing a clean glove. The naturally occurring oil that helps protect your skin has just been spread over the surface. Not only does this contaminate polyester or epoxy surfaces but the salt on your skin also speeds the corrosion of metal surfaces, which may cause adhesion problems.

Every last particle of sanding dust does not need to be removed to get good adhesion. Get the bulk of it off and consider the remaining dust as an epoxy filler. Good methods for removing sanding dust are to vacuum it off, sweep it off with a non-contaminated bench brush, or wash it off with water.

The manufacturers of sticky tack rags maintain that wiping a surface with their products will not leave a residue. However, it is probable that the rag does leave a residue although most paints and varnishes have enough solvent to remove or dissolve the residue. Epoxy, in contrast, contains none of these aggressive solvents, and the residue from sticky tack rags can cause adhesion problems and fisheyes in subsequent coats of epoxy. An alternative to a tack rag is a static wipe that is used dry and leaves no residue.

It is a common practice to use compressed air to remove sanding dust. However, aside from the mess created by blowing dust, it is possible that blowing compressed air on the surface will contaminate the surface with compressor oil or water.

Other sources of contamination

Some shop heat sources are very capable of contaminating a surface. “Torpedo” (salamander) heaters do not burn cleanly. They are capable of exhausting large amounts of moisture and hydrocarbons, which can quickly accumulate on a work surface.

Zinc stearate is applied to some types of sandpaper to keep it from loading quickly. Stearate, a chemical similar to animal fat, has the potential to create a contaminated surface just by sanding. We suggest you use aluminum oxide or waterproof wet/dry sandpaper that has not been treated with stearate.

Amine blush may be formed when epoxy cures. Amine blush is water-soluble. Many organic solvents are completely ineffective for removing it. That is why we suggest washing an epoxy surface with water (water clean enough to drink) using a Scotch Brite™ pad (or wet sanding with waterproof wet/dry sandpaper) and drying it with paper towels before continuing with another operation. Soapy water, or water with ammonia or bleach, is unnecessary and may leave a residue or other possible surface contamination.

How clean is clean enough for good adhesion?

How do you know the surface you have prepared is truly clean? Wash it with water. This unsophisticated water break test takes advantage of the fact that many contaminants repel water (that is, they are hydrophobic). In this test, water is applied to the surface with a Scotch Brite pad. If the water sheets off the surface evenly, the part is “clean.” If the water channels or beads on certain areas, the surface needs additional cleaning. You can do this test on small and large parts with equal ease. To be effective, the water used must be free of surfactants or other contamination that would cause the water to flow evenly even in the presence of contamination. The water break test will not indicate soap residues or other water-soluble films but will help remove them.

There are some materials that epoxy does not adhere to very well no matter how well you clean the surface. However, most adhesion problems can be traced to some form of surface contamination. The sources of contamination can be subtle or obvious, but when you absolutely must have good adhesion, the substrate has to be clean.

3 Steps for good adhesion

For good epoxy adhesion, bonding surfaces should be clean, dry, and sanded.

- Clean—Bonding surfaces must be free of any contaminants such as grease, oil, wax, or mold release. Clean contaminated surfaces with lacquer thinner, acetone or another appropriate solvent. Wipe the surface with paper towels before the solvent dries. Clean surfaces before sanding to avoid sanding the contaminant into the surface.

- Dry—All bonding surfaces must be as dry as possible for good adhesion. If necessary, accelerate drying by warming the bonding surface with a hot air gun, hair dryer or heat lamp. Use fans to move the air in confined or enclosed spaces. Watch for condensation when working outdoors or whenever the temperature changes.

- Sanded—Sand smooth non-porous surfaces—thoroughly abrade the surface. 80-grit aluminum oxide paper will provide a good texture for the epoxy to “key” into. Be sure the surface to be bonded is solid. Remove any flaking, chalking, blistering, or old coating before sanding. Remove dust and avoid contaminating the surface after sanding.

Special preparation for various materials

Cured epoxy—Amine blush can appear as a wax-like film on cured epoxy surfaces. It is a byproduct of the curing process and may be more noticeable in cool, moist conditions. Amine blush can clog sandpaper and inhibit subsequent bonding, but it is water-soluble and can easily be removed. It’s a good idea to assume it has formed on any cured epoxy surface. See the recommendation in the article (left) for removing blush.

Epoxy surfaces that are still tacky may be bonded to or coated with epoxy without washing or sanding. Before applying coatings other than epoxy (paints, bottom paints, varnishes, gelcoats, etc.), allow epoxy surfaces to cure fully, then wash and sand.

Hardwoods—Sand with 80-grit paper.

Teak/oily woods—Wipe with acetone 15 minutes before coating. Solvent removes the oil at the surface and allows the epoxy to penetrate. Be sure the solvent has evaporated before coating. G/flex 655 is the best choice for good adhesion to oily wood species.

Porous woods—No special preparation needed. If the surface is burnished, possibly by dull planer or saw blades, sand with 80-grit paper to open pores. Remove dust.

Steel, lead—Remove contamination, sand or grind to bright metal, coat with epoxy and then (wet) sand freshly applied epoxy into the surface. Re-coat or bond after first coat gels.

Aluminum—Sand and wipe clean. G/flex 650 is the best choice for good adhesion to aluminum

Polyester (fiberglass)—Clean contamination with a silicone and wax remover such as DuPont Prep-Sol™ 3919S. Sand with 80-grit paper to a dull finish.

Plastic—Adhesion varies. If a plastic is impervious to solvents such as acetone, epoxy generally will not bond to it. Soft, flexible plastics such as polyethylene, polypropylene, nylon, and Plexiglas fall into this category. Hard, rigid plastics such as PVC, ABS, polycarbonate, and styrene provide better adhesion with good surface preparation and adequate bonding area. After sanding, flame oxidizing (by quickly passing a propane torch over the surface without melting the plastic) can improve bonding in some plastics. G/flex 655 is the best choice for good adhesion to plastics

It’s a good idea to conduct an adhesion test on any plastic (or any other material) that you are uncertain about.