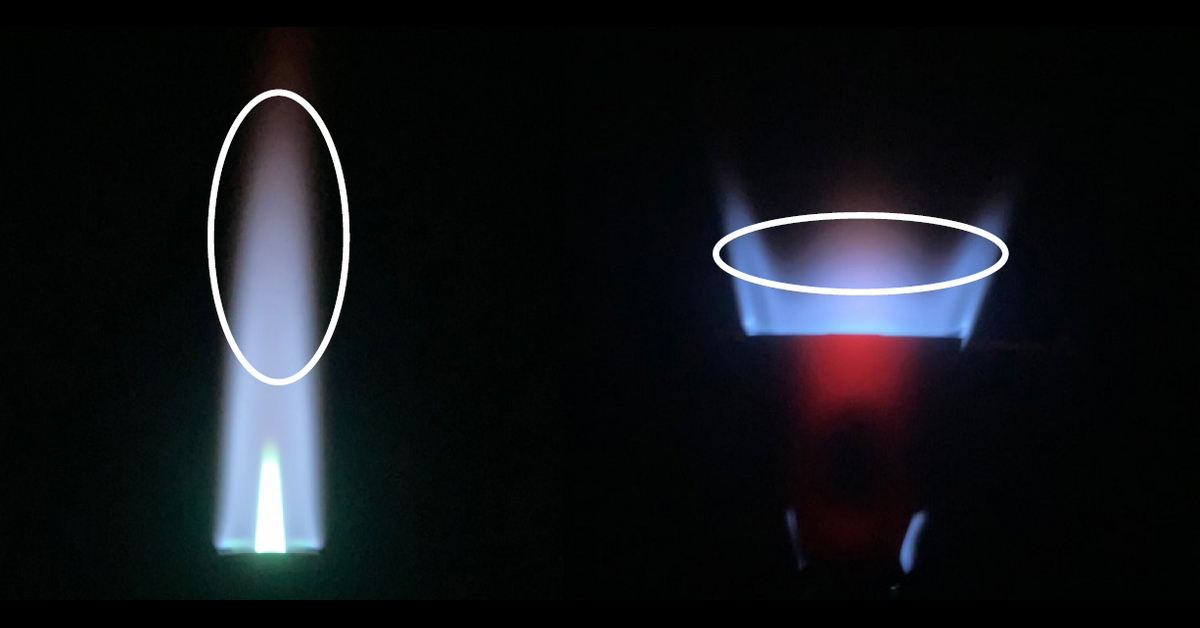

Above: The highlighted sections indicated the optimal zone for flame treating plastics. On the left is a typical propane torch flame. On the right is one with a flame spreader attachment.

by Terry Monville – GBI Technical Advisor

It’s no secret that bonding to plastic can be a challenge. Identifying what type of plastic you are working with—ABS, PVC, HDPE, LDPE, UHMWPE, and this list goes on—is your first step.

When bonding to plastic (we recommend G/flex Epoxy) surface preparation is the key. With most plastics, you achieve a higher bond strength with just an alcohol wipe and flame treatment than you would with the typical solvent wipe and sanding method required for most substrates. For example, PVC allows for an acceptable bond with a suitable solvent wipe and sanding with 80-grit sandpaper, but adhesion can be improved with flame treating. Plastics such as ABS greatly benefit from flame treating. And, for HDPE, flame treating is required, otherwise could peel the epoxy off with your fingers.

The directions that come with G/flex list how to prepare the surface for different plastics and other hard-to-bond materials. If you are in doubt about what type of plastic you are working with, sand, alcohol wipe, and flame treat for surface prep. The bond will not be impaired by the flame treatment for the plastics that do not need it.

Flame Treating Plastic to Improve Adhesion

Flame treatment is applying the exhaust from a gas flame to the surface of a material to improve adhesion.

To flame treat a plastic surface, hold a propane torch so the flame just touches the surface and move it across the surface at a rate of 12 to 16 inches per second. Keep the torch moving and overlap the previous pass slightly. Make two or three passes over the bonding area with the flame for a total of one second of exposure. When done correctly, the surface will not discolor or burn. This technique oxidizes the surface, improving adhesion without a visible change in the surface. For the best adhesion, apply the epoxy to the surface within 30 minutes of the flame treatment. The surface oxidation from the flame treatment does dissipate over time.

The flame treatment needs to be done with a flame; a heat gun will not work. At GBI we do all our characterization using a propane torch, but you can also use butane, M.A.A.P, or natural gas. Use the tip of the flame when flame treating. You can use a flame spreader to help cover more area. The flame spreader that I used created a “W” shape to the flame. Ensure the torch is close enough that the low part of the flame touches the plastic surface.

Water Break Test

The best way to test if the flame treatment was effective is with a water break test.

Oxidizing the plastic surface with a flame changes the surface from a low-energy surface to a high-energy surface. An excellent example of a low-energy surface is a waxed hood of a car. Water beads up and rolls off. An unwaxed hood would be a high-energy surface. Water sheets out, wetting the surface.

In the images below, I used blue dye in the water to make the effect on the surface before and after flame treating more obvious.

Our best product for adhering to plastics is our G/Flex Epoxy. Available in both liquid (G/flex 650) and thickened (G/flex 655), it’s a great solution to many repairs and projects with plastics.

This article is focused on bonding to solid plastic materials. When bonding a plastic fabric like Hypalon or PVC, we do not recommend flame treating the fabric surface. A simple solvent wipe and sanding with 80-grit will be the most effective on these fabric surfaces.

You can have confidence in your plastic repair or project when flame treating the surface and using our G/Flex adhesive. Flame treating solid plastic surfaces will improve the adhesion of epoxy, paint, and more.

Top: One half of a plastic board was flame treated and the other half was left natural. Water, with blue dye added for contrast, was applied. The natural side beads up ; the flame treated side sheets out. Bottom: The same board from above was wiped clean and left for an hour. The dyed water was then reapplied. The flame treatment is wearing off; the water beads up on both sides.