By Pat Dammer – GBI Lab Technician

At Gougeon Brothers Inc., customer service and support are paramount. Throughout the decades (five strong and counting), we’ve built our WEST SYSTEM® product line on a model that places customer satisfaction at the forefront. Many WEST SYSTEM users know first-hand that we strive for customer success no matter the project. Our customers’ projects range across an extremely wide spectrum. What many users may not know is the extent of product support that grinds away behind the scenes before a batch of our epoxy even hits the retail shelves. I’ll provide a look at just one of our churning gears that isn’t so obvious at first glance-quality control (QC).

When our Operations team makes a batch of a WEST SYSTEM product, they drop off a sample at our laboratory in the Technical Department for evaluation. Our Operations department labels each batch with a unique, identifying lot number designating the product, date of manufacture, and which batch it was, as they make multiple batches within a day. For example, if the lot number retain sample is 1059213B, this means the product is 105 (105 Resin), the last digit of the year of manufacture is 9 (2019), the Julian day of manufacture is 213 (August 1), and the batch of 105 produced on that specific day is B (second batch of the day).

The Technical Department begins by performing a number of tests tailored to ensure each product will perform exactly as expected out in the field. The first order of business, no matter what the product might be, is temperature conditioning. Many products are heated throughout the manufacturing process, so we must be sure the temperature at the time of testing is always consistent. We place each quality control sample, or QC retain as we call it, into a temperature-controlled bath. These baths operate at a constant temperature of 72.0°F (22.2°C) and are precise to within one-tenth of a degree. We periodically check the samples with a calibrated thermometer until they have reached the desired test temperature of 72°F.

The reactivity, or cure profile, is a very important facet of our products. It is absolutely necessary that each product cures exactly as designed. This is not only important regarding the expected cure time, but also to the end product’s performance and physical properties. There are two tests that ensure our products meet the cure profile characteristics: Peak Exothermic Temperature and Differential Scanning Calorimeter (DSC). Viscosity testing is used to evaluate the physical handling characteristics. I’ll shed some light on these analytical tests without going into the dizzying details.

Peak Exotherm

Quality control testing for Peak Exotherm is pretty simple; the title says it all. We cure a 100-gram mass of mixed resin/hardener in a standardized 120cc beaker. We place a thermocouple into the mixture and a program written specifically for this analysis monitors the heat generated vs. time. Once the mixture’s temperature hits its peak, the test is complete. Now we can view how long it took the combination to reach peak temperature during its exothermic reaction. Both the peak temperature and the time it takes to reach it must fall within a set of limits we determined through rigorous testing during product development. When the product meets the acceptable criteria, we’re confident it is curing properly and will achieve the desired properties.

Differential Scanning Calorimeter

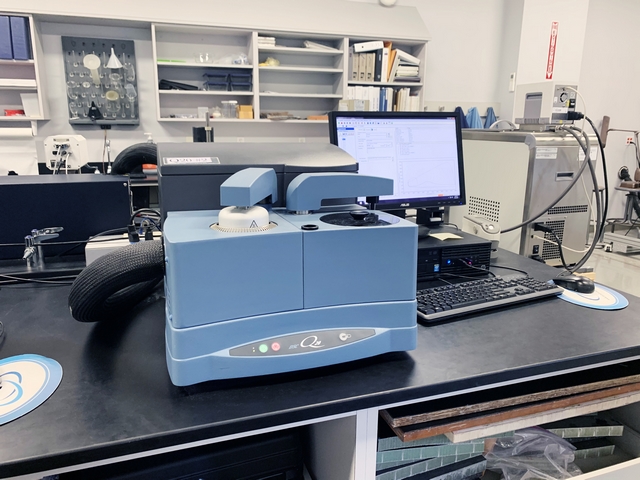

The other reactivity test is the DSC. Think of it as a tiny oven that has extremely precise temperature control and sensors to monitor the slightest change in the temperature of whatever we place in it. In addition, this oven/calorimeter can be programmed to control its temperature in any fashion ranging from -40°F to 750°F (-40°C to 400°C) via its complex software app. And to a precision that might make your head spin. As the droplet sized sample of mixed resin and hardener is put through a temperature ramp, the sensor monitors every minute change in heat flow within the sample. This data is plotted in real-time for monitoring and automatically saved once the test is complete. After interpretation, which may look like voodoo to some, we obtain specific values that directly correspond to the cure profile and thermal properties of that specific system.

The DSC is typically used to test slower curing systems where finer accuracy and a more controlled environment is needed instead of our standard Peak Exotherm test. With the slower systems, external factors such as airflow can have a greater impact skewing the test results. Again, it is through exhaustive testing that we determine the precise acceptable ranges for each resin or hardener.

Viscosity

Lastly, and maybe the simplest of the quality control tests, is measuring the material’s viscosity, or thickness. Think of the difference between water, catsup, molasses, etc. Viscosity is a property crucial to the success of each of our epoxy products.

Each product combination is designed for certain applications. Viscosity is one of the first characteristics we consider during development. In the lab, we use four viscometers to analyze the thickness and consistency of the product. In a very fancy and complex way, these instruments stir the individual resins and hardeners while monitoring their resistance to flow. The data generated provides specific values inherent to that product which must also fall within a very tight tolerance.

Other Tests

Quality control testing does not always stop at the three tests described. We have many products designed for many applications, and use other tests to ensure our specialty products perform as expected before shipment. These include color analysis, resistance to slump or sag on vertical surfaces, and even the use of lasers and mirrors… literally. However, Epoxyworks magazine does not have enough pages to attempt to explain that one.

In addition to QC testing, we measure the hardness, compression yield, tensile strength and modulus, and flexural strength and modulus of our products. We provide these cured properties to our customers on our Technical Data Sheets so they can make informed decisions about which product is best for their projects.

Final Steps

Once a product has passed all of our quality control tests with flying colors, we automatically notify our Operations Department through a company-wide quality monitoring system. Monitors/screens are located at each production station where our operators can view the progress of QC testing for each individual batch of epoxy made. This way they know as soon as each sample has passed, so they can package and ship the product.

In the lab, when the “Testing Complete” box is checked, we shelve a 16 oz. QC retain of that product batch-labeled with the unique lot number identification I explained earlier-and keep it on hand for three years. This is our record of every batch produced within that time frame, which allows for future observation and testing if needed. Every time you buy one of our WEST SYSTEM Epoxy resins or hardeners there is a sample from the same batch on standby in our lab.

We take all of these steps, every time, before allowing a batch of epoxy to go out the door, through the marketplace and into the hands of our customers.