To buy or not to buy?

Do I really need the Mini Pumps?

If it’s a two-part epoxy, why are there three pumps in the package?

The pumps look the wrong size to fit my cans. Are you sure these are the right ones?

Selling WEST SYSTEM Epoxy in a retail environment for more than 20 years, those were the three most common questions I received.

These are valid questions. We’ve all been in a situation where the salesperson is trying to upsell us or has no clue what we really need. In the case of Mini Pumps, however, the salesperson is trying to do you a favor.

You really do need Mini Pumps unless you already have a set of them, or you plan on using a scale, graduated cups, or have one of our larger pumping systems in your shop.

Why Use Mini Pumps?

WEST SYSTEM Resin and Hardener—like any epoxy—must be mixed at the correct ratio to cure properly and with the published physical properties. Too much or too little hardener will not change the speed in which it cures but instead will prevent it from properly curing. Too much hardener means once all the resin has reacted with the hardener, the extra hardener has nowhere to go. This extra hardener in the mix results in softer epoxy, or what the industry calls a “plasticizing cure.”

We formulate the ratio for 105 Resin and our 200-series hardeners to have a “fudge factor” but get outside of that forgiving stoichiometric range and problems will occur. Mixing on-ratio is always ideal, but with WEST SYSTEM products, hardener lean is better than hardener rich. This is why you really want to buy a set of calibrated 300 Mini Pumps. One full pump stroke of resin to one full pump stroke of hardener will yield the proper volume of each.

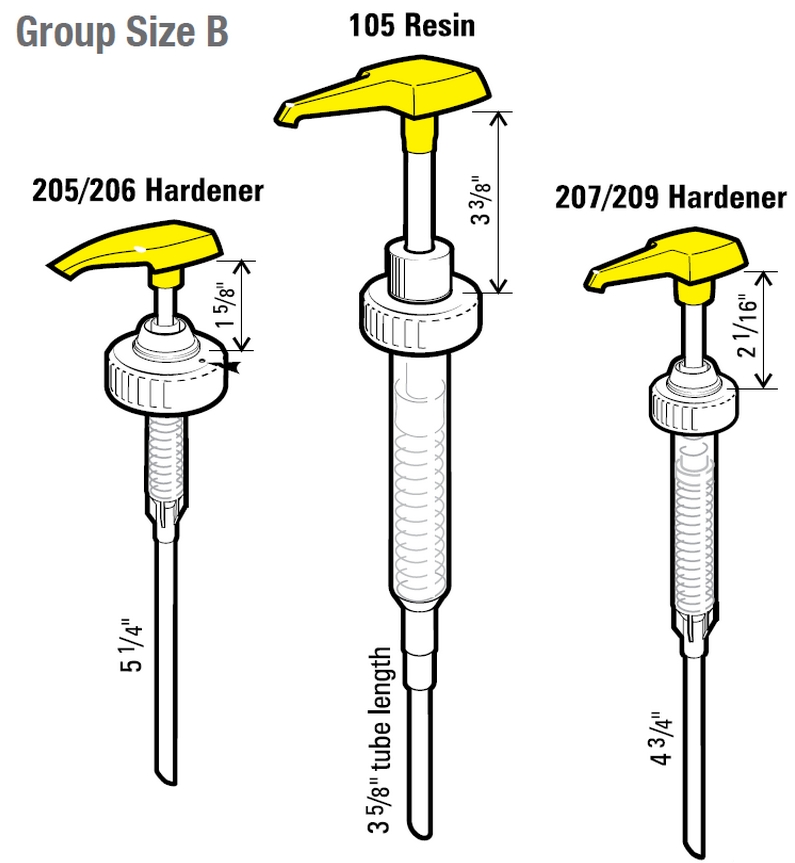

WEST SYSTEM is based on the 105 Resin and four 200 series hardeners (205 Fast, 206 Slow, 207 Special Clear, and 209 Extra Slow). When installing the pumps, put the resin pump on first. It’s the largest pump and has Resin printed on top. You are now left with two pumps with Hardener printed on the top. The larger diameter screw-on cap will fit the 205 and 206 hardeners and the one with the smaller diameter screw-on cap fits the 207 and 209 hardeners.

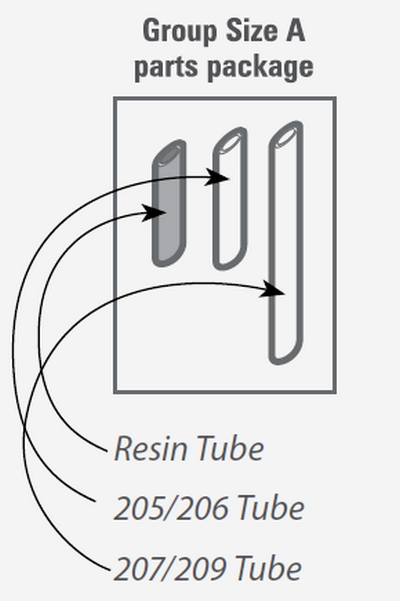

The pumps come set up to fit the “B” size group (gallon of 105 Resin) of epoxy. Shorter extension tubes are packaged with the pumps to fit the “A” size group (quart of 105 Resin). Before fitting pumps into your A-size resin and hardener cans, remove the extension tube from the bottom of the pumps and replace with the smaller extensions. If you plan on using the pumps on a “C” size of WEST SYSTEM Epoxy, you’ll find those larger extensions packaged in the box containing your “C” group resin and hardener.

Getting the most out of Mini Pumps

Now that you made the right decision and bought the pumps, here’s how to make the most of your purchase.

When you first install the pumps, check to make sure the resin pump is ready to use. Hold the white cap that screws onto the can and the clear plastic pump barrel and make sure they are screwed together snugly. You will also want to check on this from time to time.

Priming the pumps before the first use is simple but important; the instructions in the package explain how to do this. You will want to check the prime if the pumps been sitting for a long time, or when changing cans.

That’s right, when changing cans. No need to buy new pumps every time you buy new cans of epoxy. Store the pumps right on the cans and when you run out of WEST SYSTEM Epoxy you can move your pumps to the new cans of resin and hardener.

If the pumps have been sitting on the cans for a while they may develop a crust on the end of the spout. Hardener pumps particularly seem to do this. The crust is easily cleaned away: just break it off and wipe the spout. You can use warm water to clean the hardener pumps and acetone or denatured alcohol for the resin pump, if needed.

Use only full pump strokes and do not pull up on them, let them return on their own. Alternating one stroke of resin and one stroke of hardener eliminates the need to count strokes and reduces the time spent waiting for the pumps to return to the top of their stroke. Slow pump return can be an issue when using epoxy in cooler weather when the epoxy becomes “thicker” (actually, more viscous as our chemists would say). Try to keep your resin and hardener warm even if what you’re working on isn’t. Mix your epoxy indoors if you’re working at low temperatures in the garage. In the boatyard, an empty cooler and a shop light with an incandescent 15-watt bulb will keep your resin and hardener nice and warm.

Remember, warm epoxy will cure faster until it hits the cool/cold surface. Call and talk to one of our Technical Advisors about cold temperature bonding applications, or check our User Manual & Product Guide, visit westsystem.com, or see “Cold Weather Bonding” by Don Gutzmer in Epoxyworks 43.

Lastly, long-time WEST SYSTEM users may still have pumps with white tops (which we stopped selling back in 2002). The white-top pumps and the newer yellow top pumps are not compatible and should not be combined. But as long as your old white-top pumps are still delivering resin and hardener on ratio (verified by a simple pot-life test), they’re good. See, we told you Mini Pumps were reusable.